Compressed garbage truck

A garbage truck and compression type technology, which is applied in the directions of garbage receptacle, transportation and packaging, can solve the problems of energy consumption of hydraulic system and unfavorable efficient utilization of energy, and achieve the effect of improving compression efficiency and reducing the number of repeated compressions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

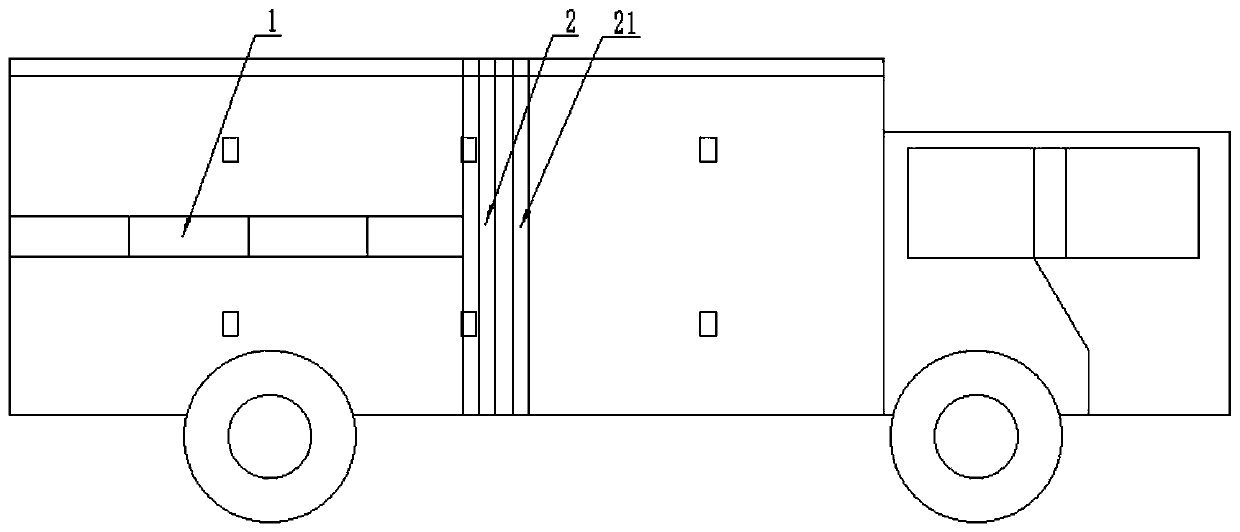

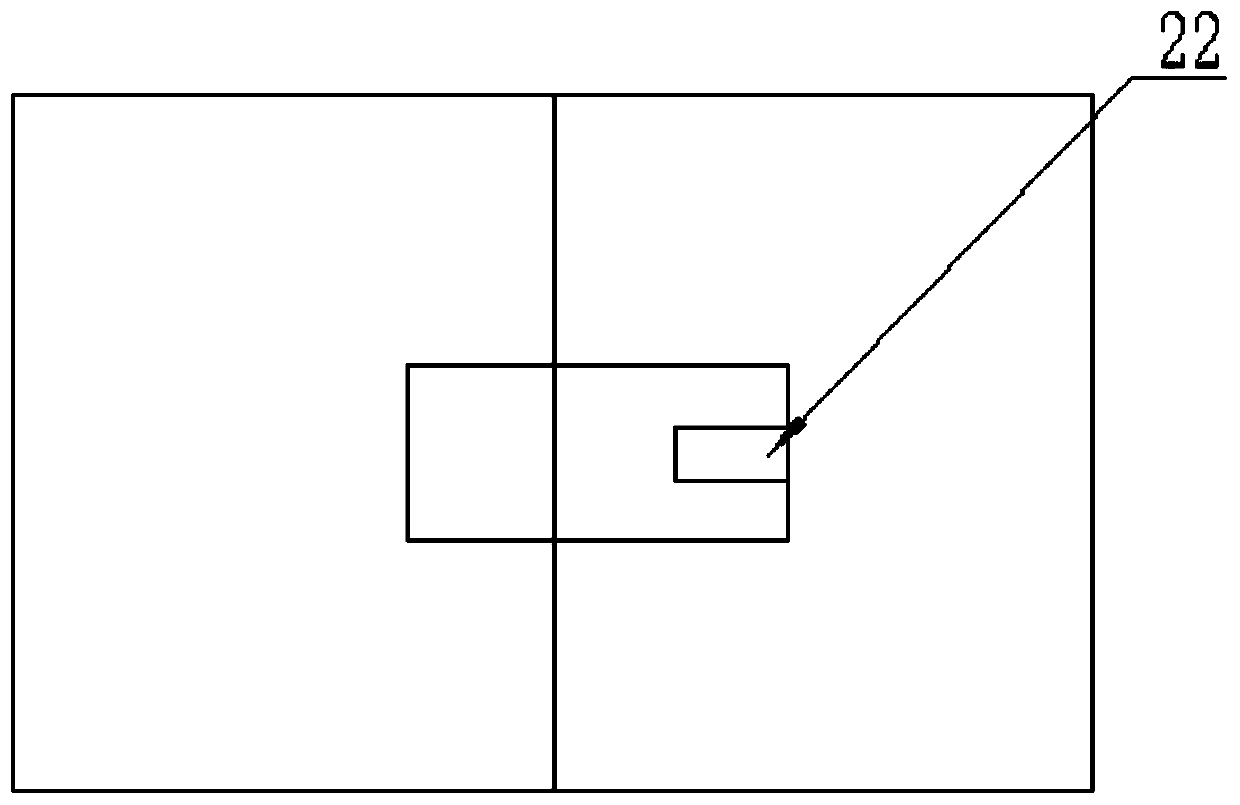

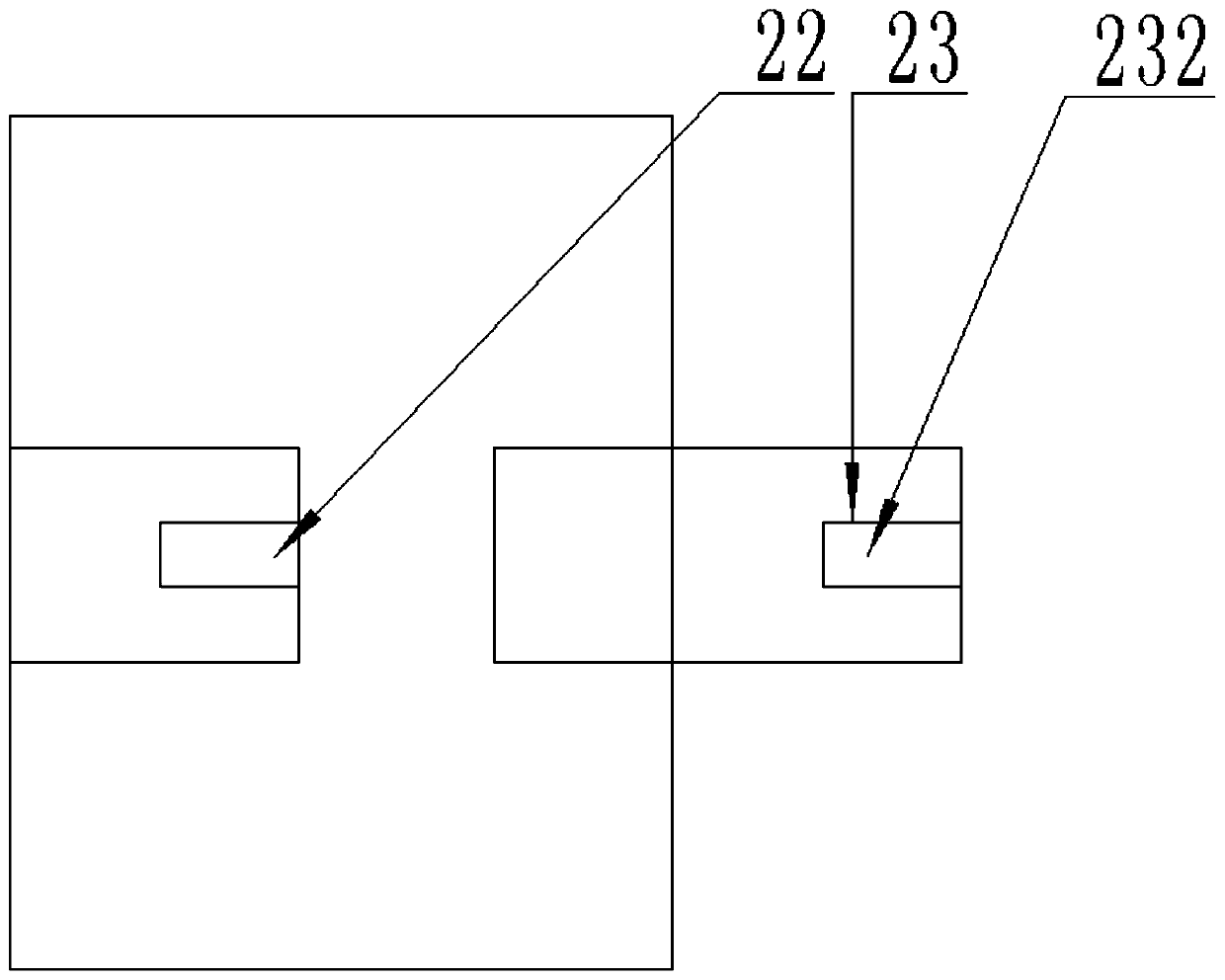

[0018] A compression garbage truck is provided based on the above purpose, the compression garbage truck includes a head and a carriage, and a compression module is arranged behind the carriage. The compression module includes a hydraulic compression rod 1 and an extruding plate 2 arranged at the end of the hydraulic compression rod 1; the extruding plate 2 protects the multi-layer sub-pressing plate 21 stacked on top of each other, and the side of the sub-pressing plate 21 facing the direction of the front of the vehicle is provided with a convex Out of the buckle, the side of the sub-press plate 21 facing away from the direction of the front of the car is provided with a groove that cooperates with the protruding buckles of other sub-press plates 21; the side wall of the groove is provided with a locking groove 22, and the side wall of the protruding buckle is provided with There is a receiving hole 23, and a movable block 232 cooperating with the locking groove 22 is arrange...

specific Embodiment 2

[0023] Further, in order to be able to identify the alignment time of the receiving groove 24 and the positioning hole and control the time window for separating the adjacent sub-press plate 21, a slide rail is provided on the inner top of the compartment, and an insertion slide rail is provided on the top of the sub-press plate 21 There are several trigger switches in the slide rail, the number of rows of trigger switches is the same as that of positioning holes, the vertical plane of the row of trigger switches coincides with the vertical plane of the row of positioning holes, and the trigger switches are respectively connected to the The two telescopic rods are electrically connected with the pressure sensor. When the pressure sensor detects that the pressure received by the outermost sub-platen 21 reaches the set reset value, when the trigger switch is touched by the slider, the trigger switch controls the extension of the second telescopic rod, and the positioning block 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com