An optical fiber distribution frame with a multifunctional module

An optical fiber distribution frame and multi-functional technology, which is applied in the field of optical fiber distribution frames, can solve the problems such as the inability to use double-sided optical fiber distribution frames, and achieve the effect of reducing the use cost and preventing loosening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

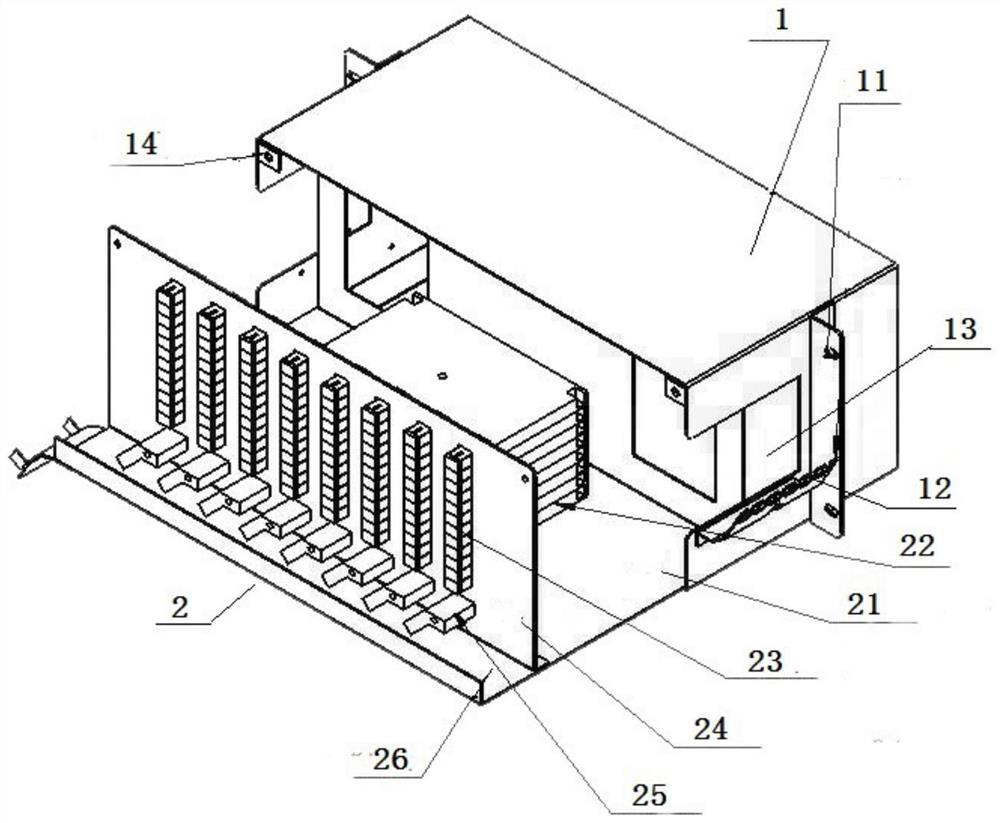

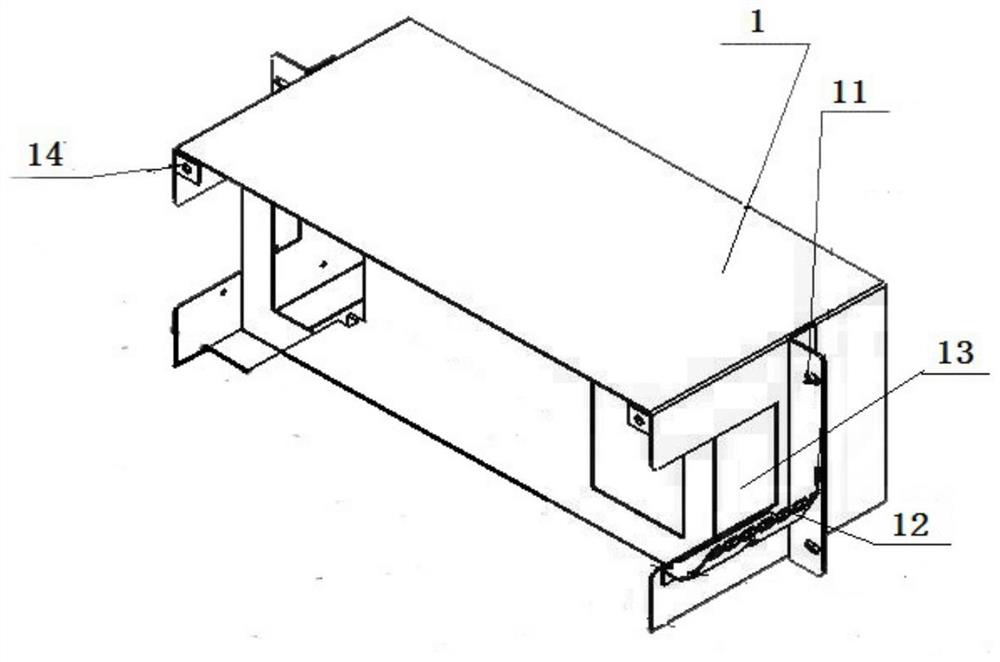

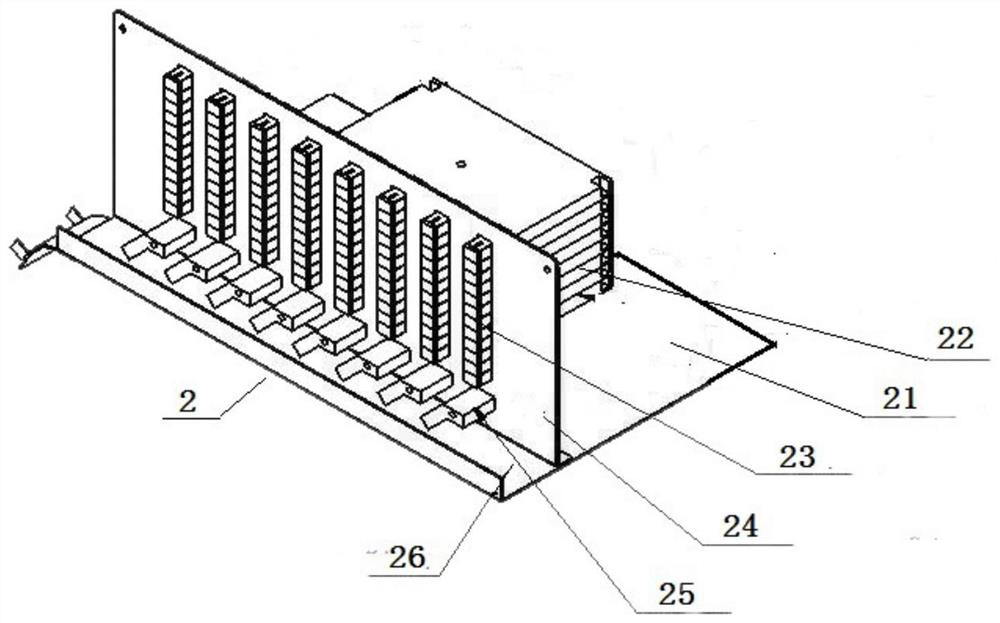

[0029] Such as Figure 1 to Figure 4 As shown, a fiber optic distribution frame with multi-functional modules includes a multi-functional module box 1 and a module frame 2; It is connected with the rack; the module frame 2 is provided with a fiber splicing tray 21 and a splicing tray 22, and the splicing tray tray 21 can be drawn and placed in the multifunctional module box 1, and the splicing tray tray 21 is placed A splicing tray 22 is installed, and the splicing tray 22 provides a place for fusion splicing of the incoming optical cable and the pigtail, and the pigtail is connected with the adapter 23 . The side wall of the multifunctional module box 1 of the distribution frame is equipped with an incoming optical cable fixing plate 12, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com