Cleaning tool for optical connector

A technology for optical connectors and cleaning tools, which is applied in the coupling of optical waveguides, instruments, optics, etc. It can solve the problems of pushing the cleaning body that cannot clean the tool, and the shell that cannot fit the shell and the backplane connector. , to achieve the effect of easy fitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

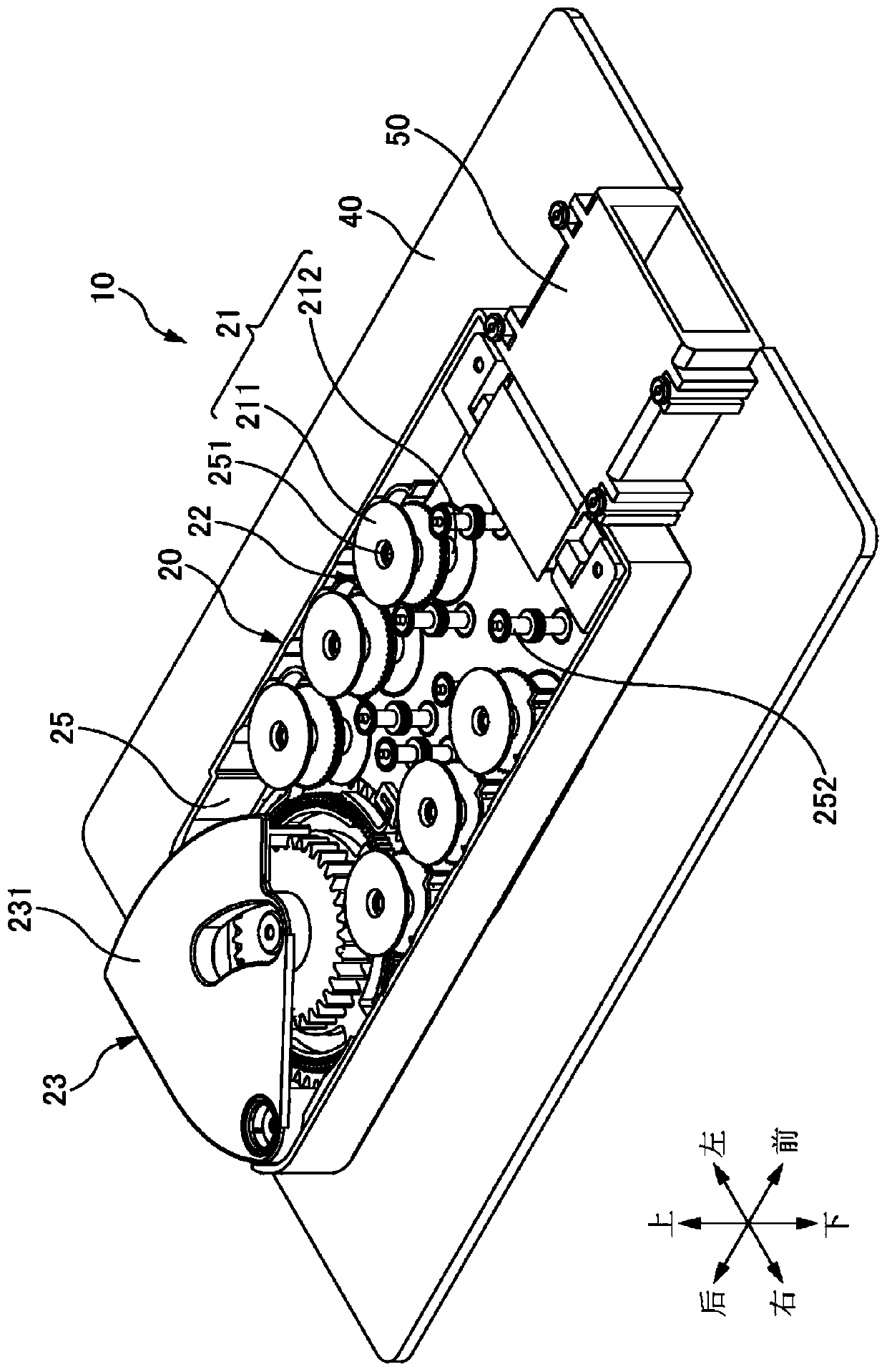

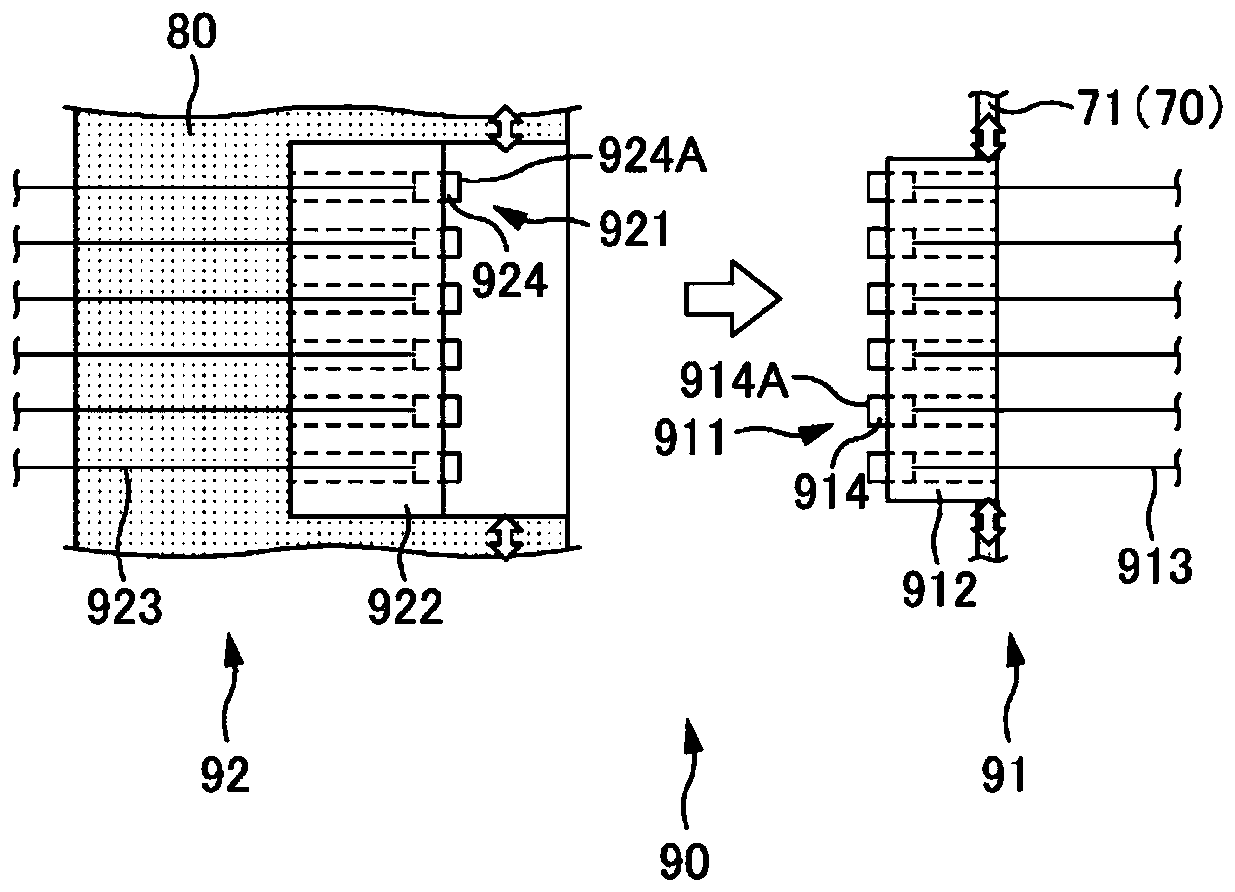

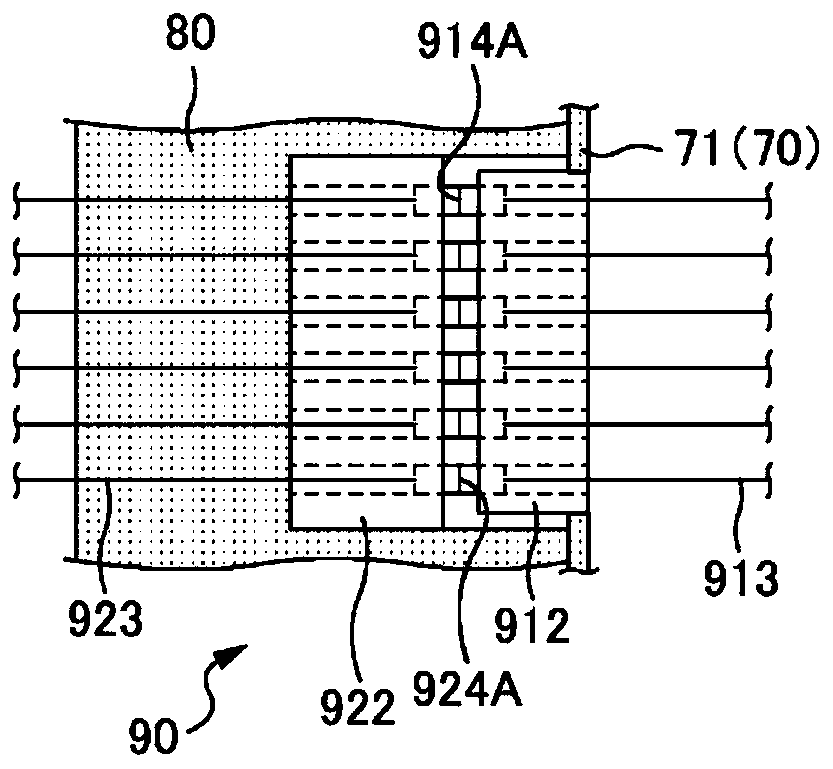

[0022] At least the following matters are clear from the description in the specification and drawings described later.

[0023] A cleaning tool for an optical connector, which can be clearly characterized as having: a main body; a base plate on which the main body is fixed; and a head unit that pushes the cleaning body against The head of the above-mentioned optical connector and the head housing for accommodating the above-mentioned head are formed so as to be fitted with the housing of the above-mentioned optical connector, and the above-mentioned head unit is provided so as to be capable of facing each other. Move on the above substrate. According to such a cleaning tool for an optical connector, the cleaning tool can be easily fitted to the housing of the optical connector to be cleaned.

[0024] It is preferable to include a stopper mechanism that restricts a movement range of the head unit relative to the substrate. Thereby, detachment of the head unit from the substr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap