Blasting safety analysis method and analysis system based on continuous digital vibration measurement

A safety analysis and vibration measurement technology, applied in the direction of measuring blasting force, analyzing materials, measuring devices, etc., can solve the problem of difficult to accurately reflect the actual situation, and achieve the effect of timely alarm and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

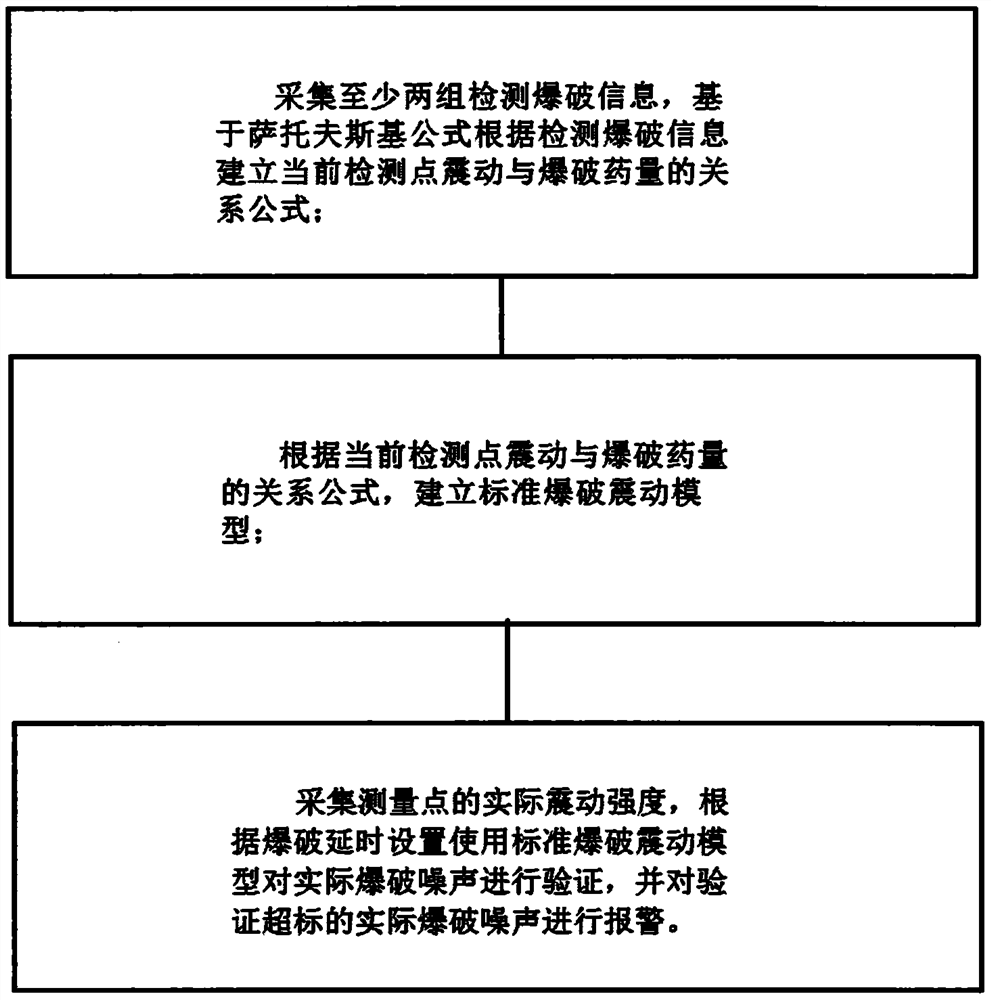

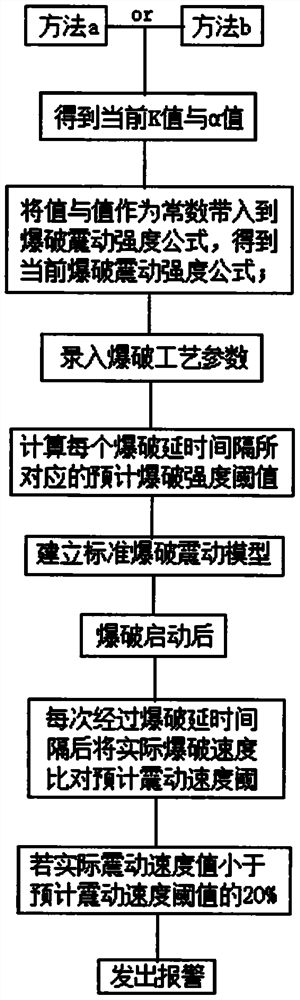

[0041] like figure 1 As well as 2 It shows a blasting safety analysis method based on continuous digital vibration, including establishing a standard vibration model and continuous inspection blasting vibration.

[0042] Generate current blasting vibration strength formula

[0043] First detect the currently changing parameter K value and α value, the K value and α value are the environmental coefficient and attenuation index related to the current blasting point to the detection point, including the two methods of A and B, which are specific. as follows:

[0044] Methods A. Set up detecting civil explosive products on the blasting working surface. The detection of civilian explosive products is the same as the current project for the use of civil explosive products. In order to reduce the detection cost, the detection of the explosives of the civilian product is 1-2 units of thunder tubes, digital traces, and explosives of 1-2 units. For the people of the people, the inspection o...

Embodiment 2

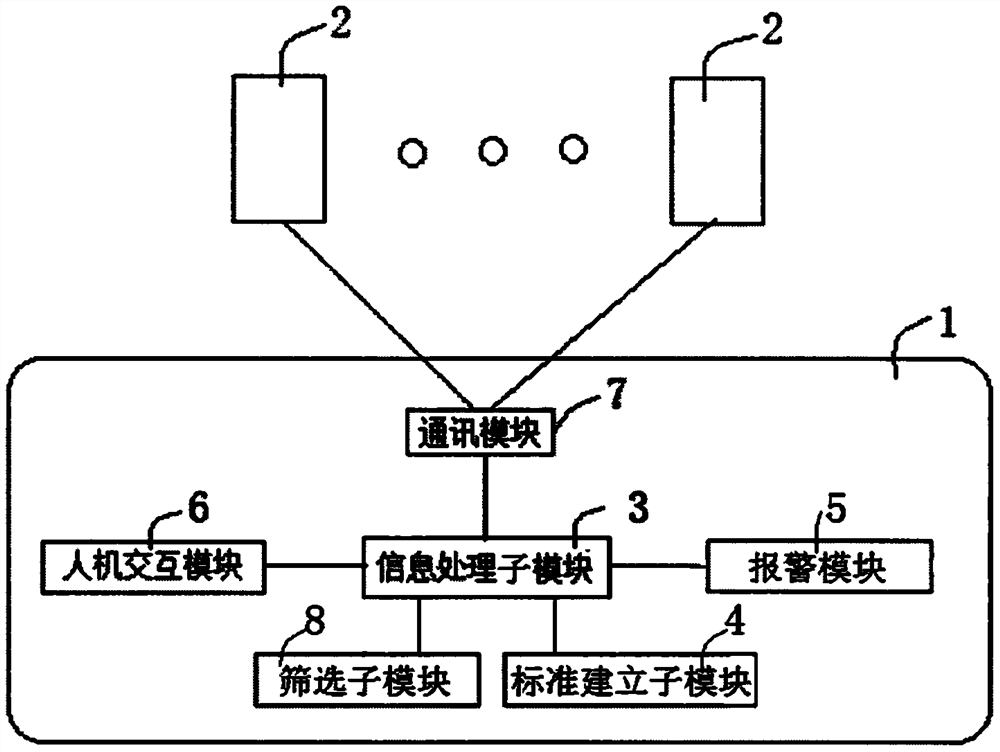

[0082] like image 3 Show, an analysis system that uses a blasting safety analysis method based on continuous digital vibration, including data processing center 1 and vibration meter 2. 6. Communication module 7, the processor connects the alarm module 5, the human -machine interaction module 6 and the communication module 7, the communication module 7 between the communication connection between the communication module 7 3 and Standard Create Sub -Module 4.

[0083] like Figure 4 The product model of the microprocessor 9 is STM32F103RCT6. The microprocessor 9 has an information processing submuct 3 and a standard for establishing a sub -module 4. The lattice module function is as follows:

[0084] At least two sets of inspection parameters received by information processing submissions 3 are passed to the standard establishment submissile 4, standard establishment of sub -module 4 receiving detection parameters and calculating the current blasting vibration strength formula thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com