Transmission shaft forging forming process and forging die

A forming process and transmission shaft technology, applied in the field of forging, can solve the problems of high energy consumption, large consumption of materials, and increased projection area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

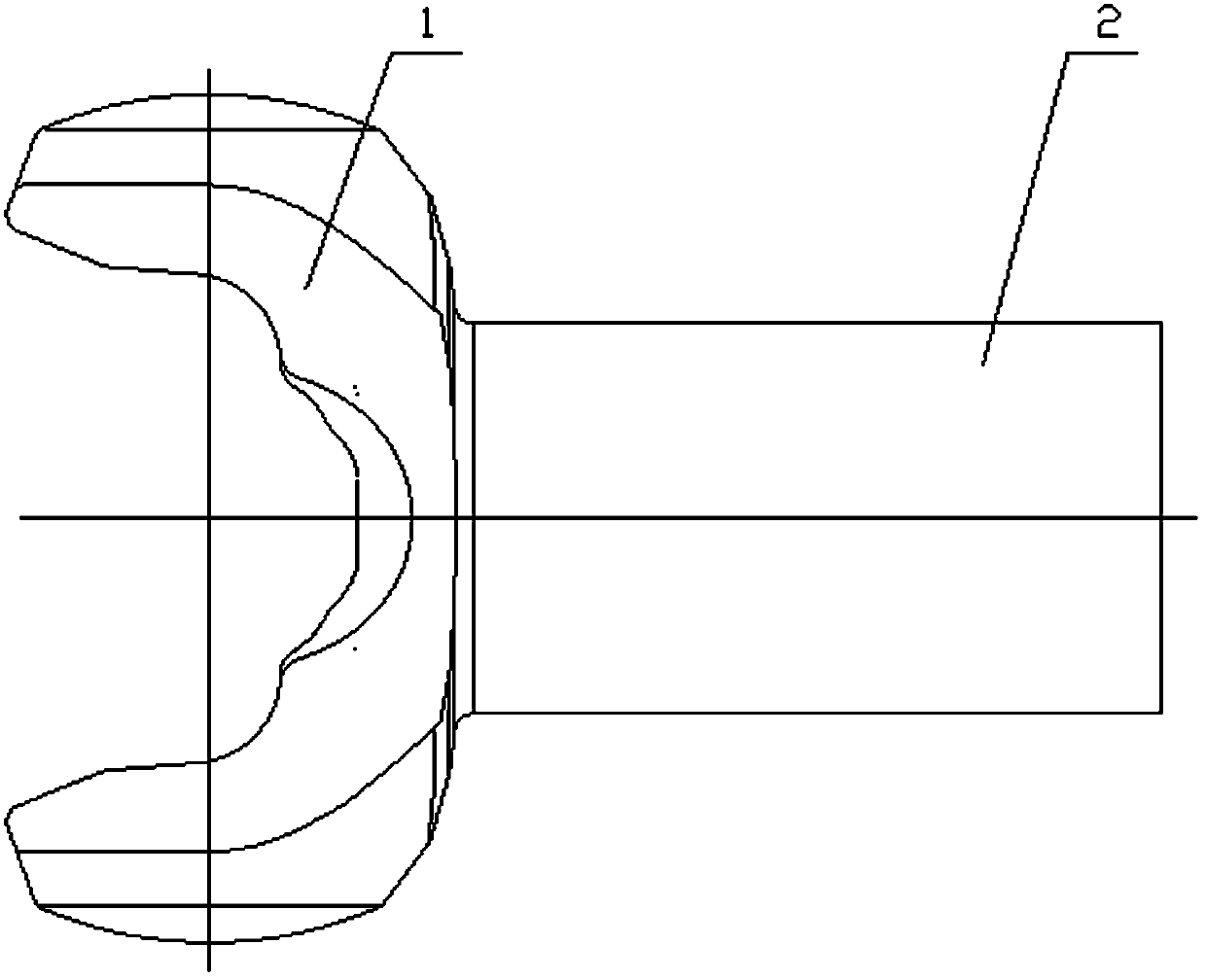

[0026] A transmission shaft forging forming process, which includes the following processing steps: blanking - heating - heading - forging - trimming - heat treatment, using small-sized bars for blanking, and upper and lower forging. Die vertical forging, such as image 3 As shown, the transmission shaft forging is formed by connecting the fork 1 and the rod 2. The parting surface of the transmission shaft forging is a curve designed according to the shape of the fork, and the parting surface is composed of B1-B2-B3-B4 -The six points of B5-B6 are connected to form a curve, and the parting surface can divide the fork head into upper and lower parts.

[0027] Adopting the above-mentioned technical scheme, because the small-sized bar is used for processing, and the parting surface is designed based on the fork head, and the vertical forging is used instead, the production efficiency is improved, the deficiency of the existing technology is overcome, and the forming force of the ...

Embodiment 2

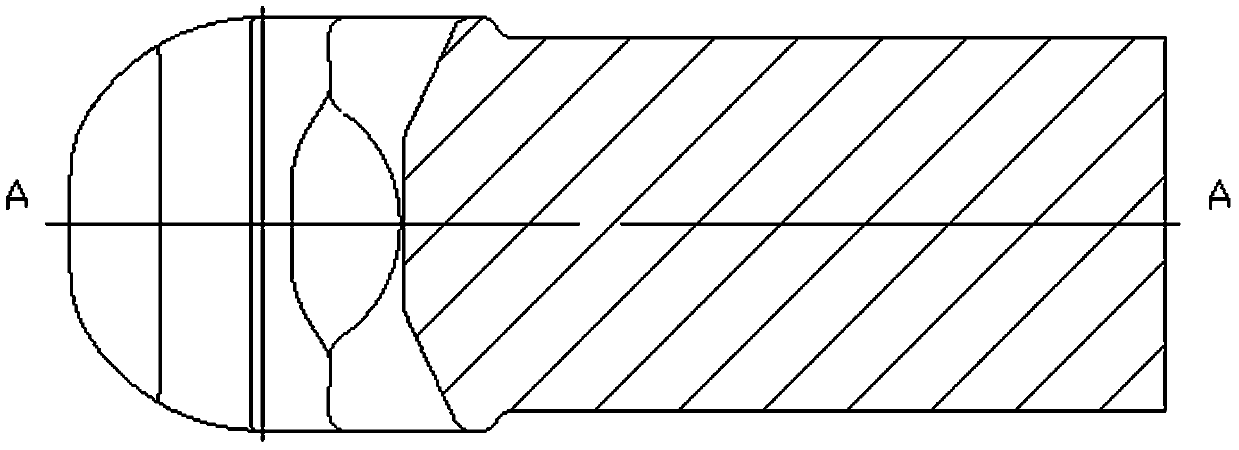

[0029] A transmission shaft forging die, the transmission shaft is formed by connecting a fork and a rod, such as Figure 4 , 5 As shown, the forging die includes an upper die 3 and a lower die 4, the die surface of the lower die 4 is provided with a cavity 4a adapted to the shape of the outer surface of the drive shaft yoke and bridges on the left and right sides of the cavity 4a part 4b, the bridge part 4b communicates with the cavity 4a; a through hole 4c is provided downward in the center of the bottom of the cavity 4a, and the aperture of the through hole 4c gradually becomes smaller from top to bottom; the mold surface of the upper mold 3 is provided with A downward protruding punch 3a, the structure of the punch 3a is adapted to the shape of the inner surface of the transmission shaft yoke, the mold surface of the upper die 3 is respectively provided with a groove 3b on the left and right sides of the punch 3a, and the left and right sides The grooves 3b are symmetrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com