Belt ply laminating drum mechanism with two supported sides

A technology for laminating drums and belt layers, applied to tires, other household appliances, household appliances, etc., can solve problems such as sagging of rubber belt layers, achieve the effects of improving the effect, improving product quality, and reducing product costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

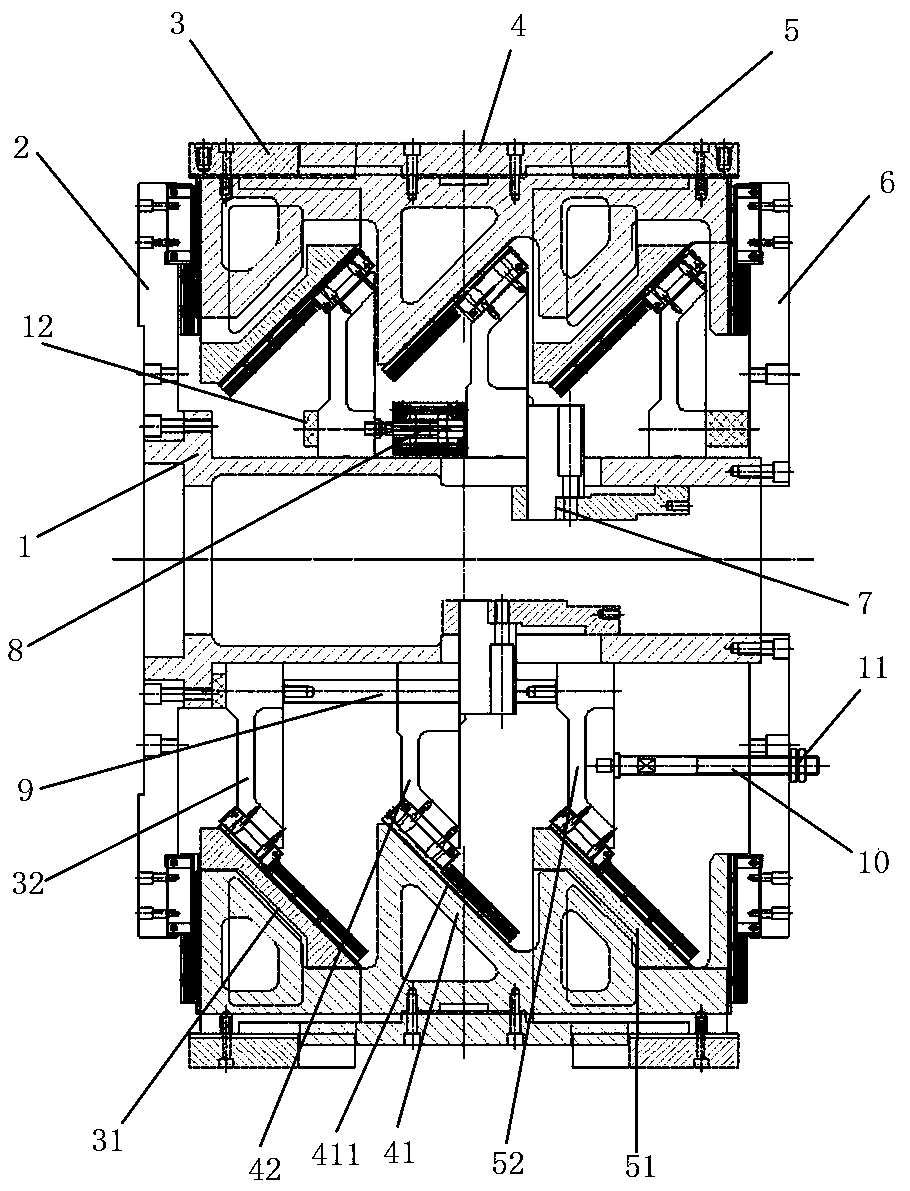

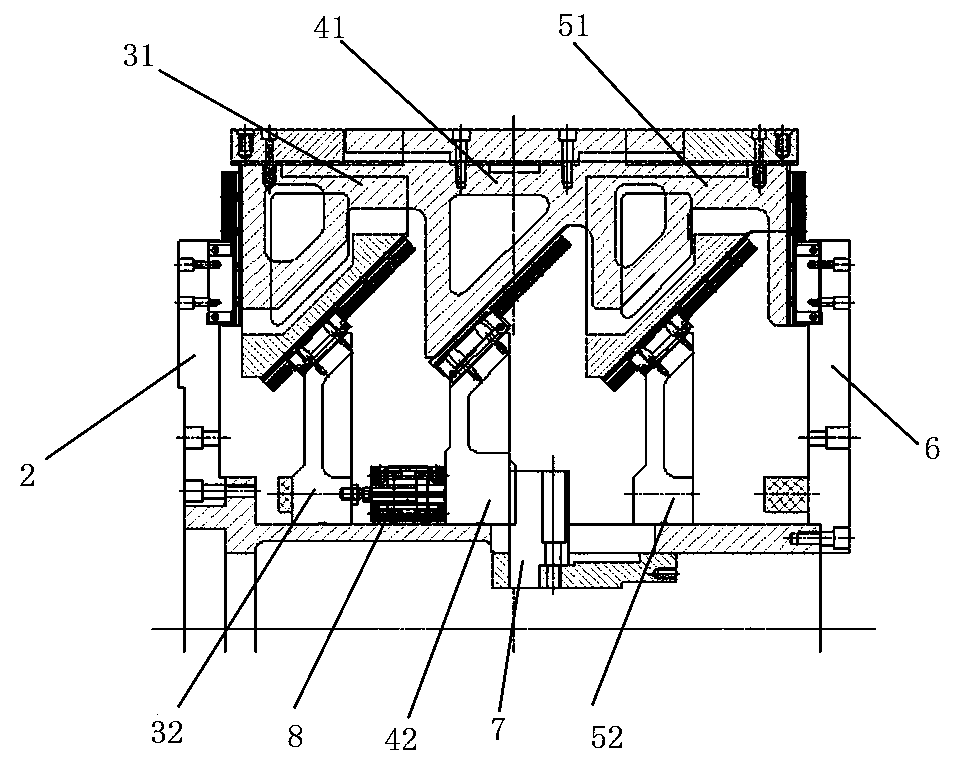

[0015] As shown in the figure: a belt laminating drum mechanism supported on both sides, including a main shaft 1 and a left guide disc 2, a left drum plate 3, a middle drum plate 4, a right The drum plate 5 and the right guide plate 6, the left drum plate 3 forms a radial sliding connection with the left guide plate 2 through the left slider 31, and the right drum plate 5 forms a radial direction with the right guide plate 6 through the right slider 51. Sliding connection, the middle drum plate 4 is fixedly connected with the middle slider 41, the middle slider 41 includes an inclined surface 411 and is slidably connected with the middle sliding seat 42 through the inclined surface 411, a push rod 7 is arranged inside the main shaft 1, The push rod 7 protrudes from the middle position of the main shaft 1 and is fixedly connected with the middle sliding seat 42. The middle sliding seat 42 moves back and forth along the axial direction of the main shaft 1 under the push of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com