Super-long water filtering pipe wire wrapping machine

A technology for a water filter pipe and a wire wrapping machine, which is applied in the field of an ultra-long water filter pipe wire wrapping machine, can solve the problems of power consumption, manpower and material resources, affecting the progress of the downhole, and poor pressure resistance of the assembled welded water filter pipe.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

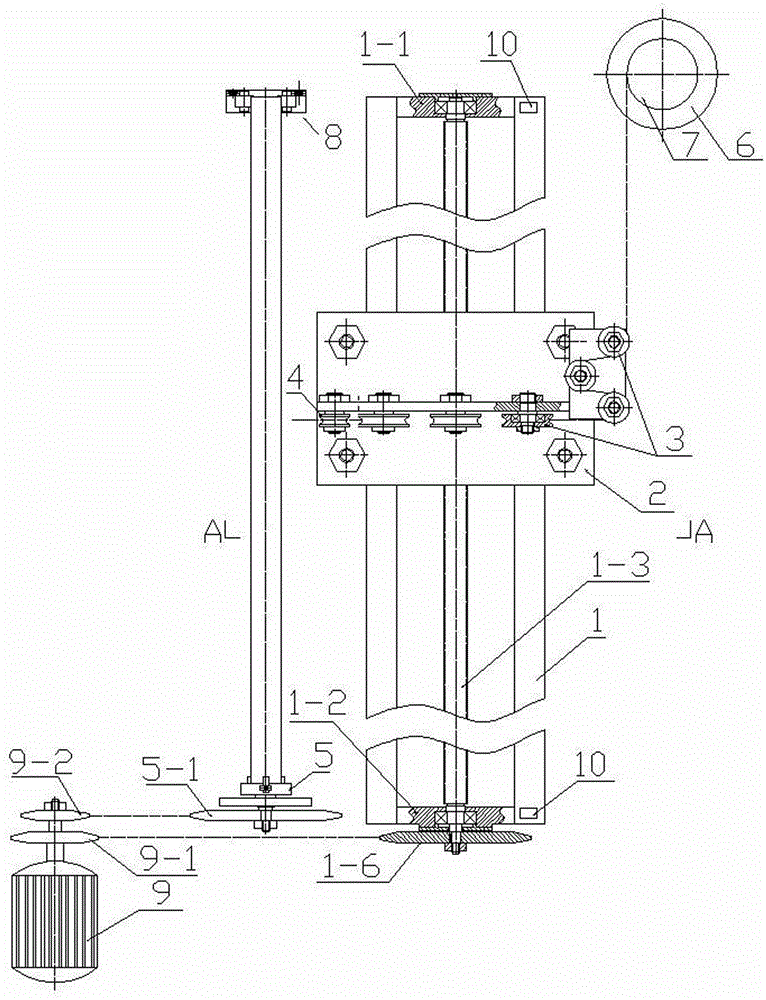

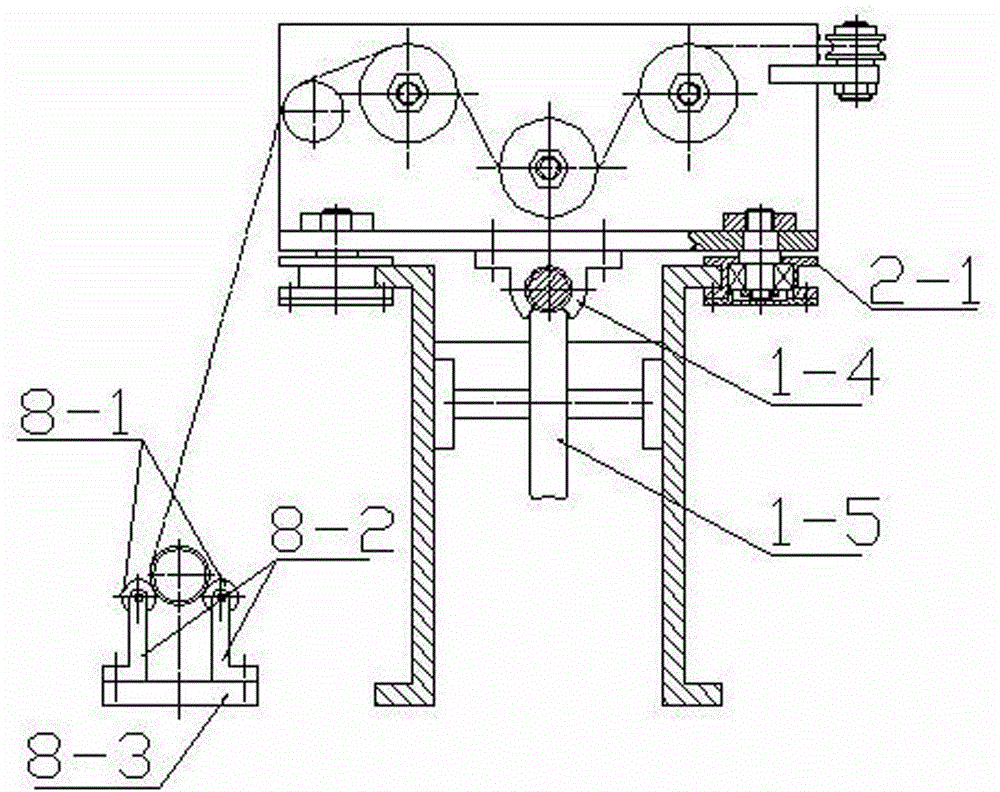

[0014] As shown in the figure, the ultra-long filter pipe winding machine is composed of a power mechanism, a winding mechanism and a wire releasing mechanism 6. The winding mechanism includes a frame 1 and a tube chuck 5 and a tube The end lifting device 8 is fixed with bearing blocks 1-1, 1-2 at the two ends of the H-shaped frame 1, and is fixed with a screw 1-3 by the rotation of the bearing blocks 1-1, 1-2, and is fixed on the frame 1. The middle part is provided with the shuttle-shaped lifting wheel 1-5 that prevents the lead screw from jumping, and the traveling pallet 2 is provided on the frame 1, and the screw-shaped lifting wheel 1-5 is screwed on the leading screw 1-3. The shuttle-shaped nuts 1-4 that pass through without obstacles are provided with a thread adjusting wheel group 3 and a head stabilizing wheel 4 on the walking pallet 2, and the power mechanism is connected with the tube chuck 5 and the lead screw 1-3, and the tube clamps The speed of rotation of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com