Automatic decorticator for ramie

A ramie stripping machine, automatic technology, applied in mechanical processing, fiber mechanical separation, textiles and papermaking, etc., can solve the problems of unclean ramie tail peeling, high labor intensity, high ramie glue content, and achieve convenient field. Moving or working in the field, low labor intensity, good quality of hemp stripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

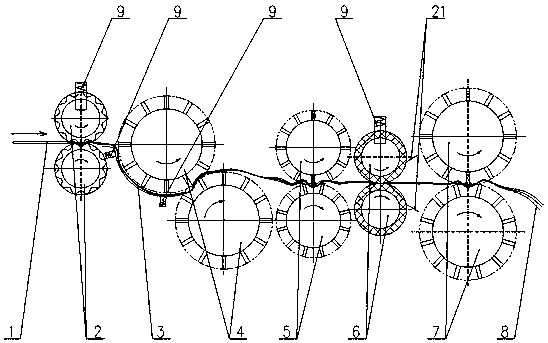

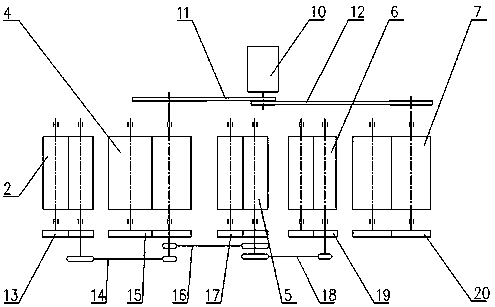

[0027] Such as figure 1 Shown, a kind of automatic hemp stripping machine comprises: hemp pressing roller 2, concave plate 3, stripping hemp roller 4, clamping hemp roller 5, drawing hemp roller 6, anti-wrapping hemp device 21, combing hemp roller 7, from feeding From the mouth to the discharge port, there are successively provided with a pressing roller 2, a peeling roller 4, a clamping roller 5, a pulling roller 6, an anti-wrapping device 21 and a combing roller 7, and the peeling roller 4 is composed of the upper peeling roller. Constituted with the lower hemp-peeling roller, the concave plate 3 is arranged under the upper hemp-peeling roller, and the spring 9 is arranged below the concave plate 3, which can automatically adjust the gap between the concave plate 3 and the upper hemp-peeling roller to prevent material from clogging.

[0028] Described embossing roller 2 is made of upper embossing roller and lower embossing roller, and the roller surface of upper embossing ro...

Embodiment 2

[0039] Such as figure 1 Shown, a kind of automatic hemp stripping machine comprises: hemp pressing roller 2, concave plate 3, stripping hemp roller 4, clamping hemp roller 5, drawing hemp roller 6, anti-wrapping hemp device 21, combing hemp roller 7, from feeding From the mouth to the discharge port, there are successively provided with a pressing roller 2, a peeling roller 4, a clamping roller 5, a pulling roller 6, an anti-wrapping device 21 and a combing roller 7, and the peeling roller 4 is composed of the upper peeling roller. Constituted with the lower hemp-peeling roller, the concave plate 3 is arranged under the upper hemp-peeling roller, and the spring 9 is arranged below the concave plate 3, which can automatically adjust the gap between the concave plate 3 and the upper hemp-peeling roller to prevent material from clogging.

[0040] Described embossing roller 2 is made of upper embossing roller and lower embossing roller, and the roller surface of upper embossing ro...

Embodiment 3

[0049] Such as figure 1 Shown, a kind of automatic hemp stripping machine comprises: hemp pressing roller 2, concave plate 3, stripping hemp roller 4, clamping hemp roller 5, drawing hemp roller 6, anti-wrapping hemp device 21, combing hemp roller 7, from feeding From the mouth to the discharge port, there are successively provided with a pressing roller 2, a peeling roller 4, a clamping roller 5, a pulling roller 6, an anti-wrapping device 21 and a combing roller 7, and the peeling roller 4 is composed of the upper peeling roller. Constituted with the lower hemp-peeling roller, the concave plate 3 is arranged under the upper hemp-peeling roller, and the spring 9 is arranged below the concave plate 3, which can automatically adjust the gap between the concave plate 3 and the upper hemp-peeling roller to prevent material from clogging.

[0050] Described embossing roller 2 is made of upper embossing roller and lower embossing roller, and the roller surface of upper embossing ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com