Axial elastic gear and flexible joint mechanism

A technology of flexible joints and elastic gears, applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve problems such as restricting the flexibility of the driven shaft and affecting the normal operation of machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

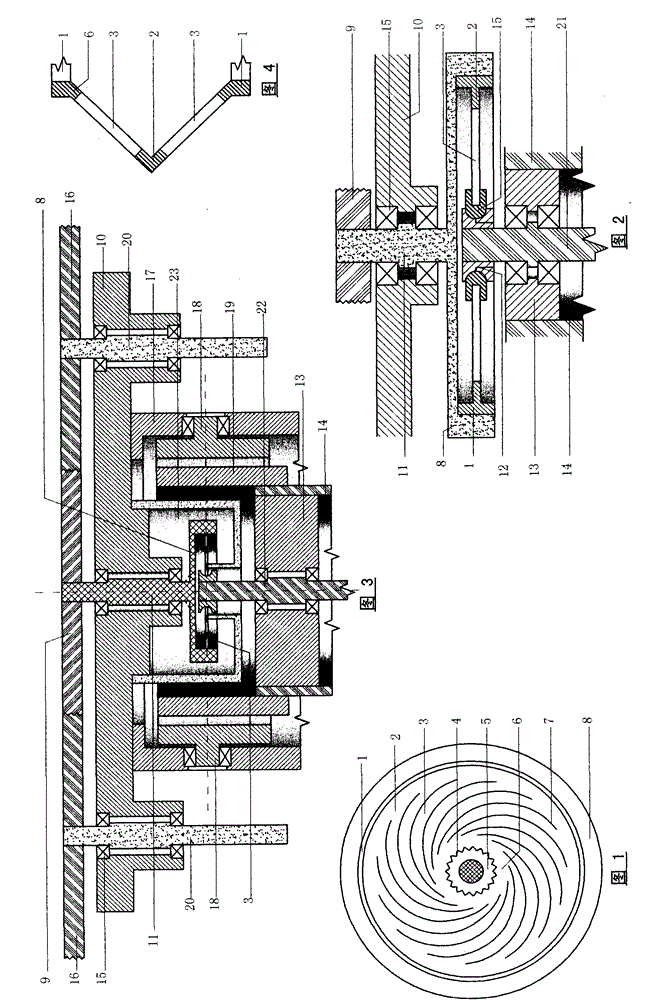

[0026] Select the mechanism shown in Figure 2, and press the disc with the teeth shown in Figure 1.

[0027] 1. Making disc teeth

[0028] 1. Make a disc:

[0029] a. Select a spring steel plate and cut it into 2 rings;

[0030] b. Cut the middle of the ring into the involute or other arc type shown in Figure 1 by means of laser cutting, etc., and divide the middle into several spiral spokes;

[0031] c. Cut the inner holes of the two rings into inner teeth (round-head core teeth are not used in this example).

[0032] 2. Production of dish teeth:

[0033] a. First make a rigid ring with an inner diameter equal to the outer diameter of the disc, as a mounting rib for the disc teeth;

[0034] b. Stack and fix the two discs according to the spiral direction of the involute, one reverse and one forward, and leave a certain gap between the two discs so that the axial elastic deformation capabilities of the two discs do not affect each other;

[0035] c. Fix the stacked and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com