Bracket for assisting movement of automobile

A technology for automobiles and connecting blocks, applied in vehicle maintenance, shunting equipment, vehicle control devices, etc., can solve problems such as broken connecting rods, and achieve the effects of improving stability, simple structure, and obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

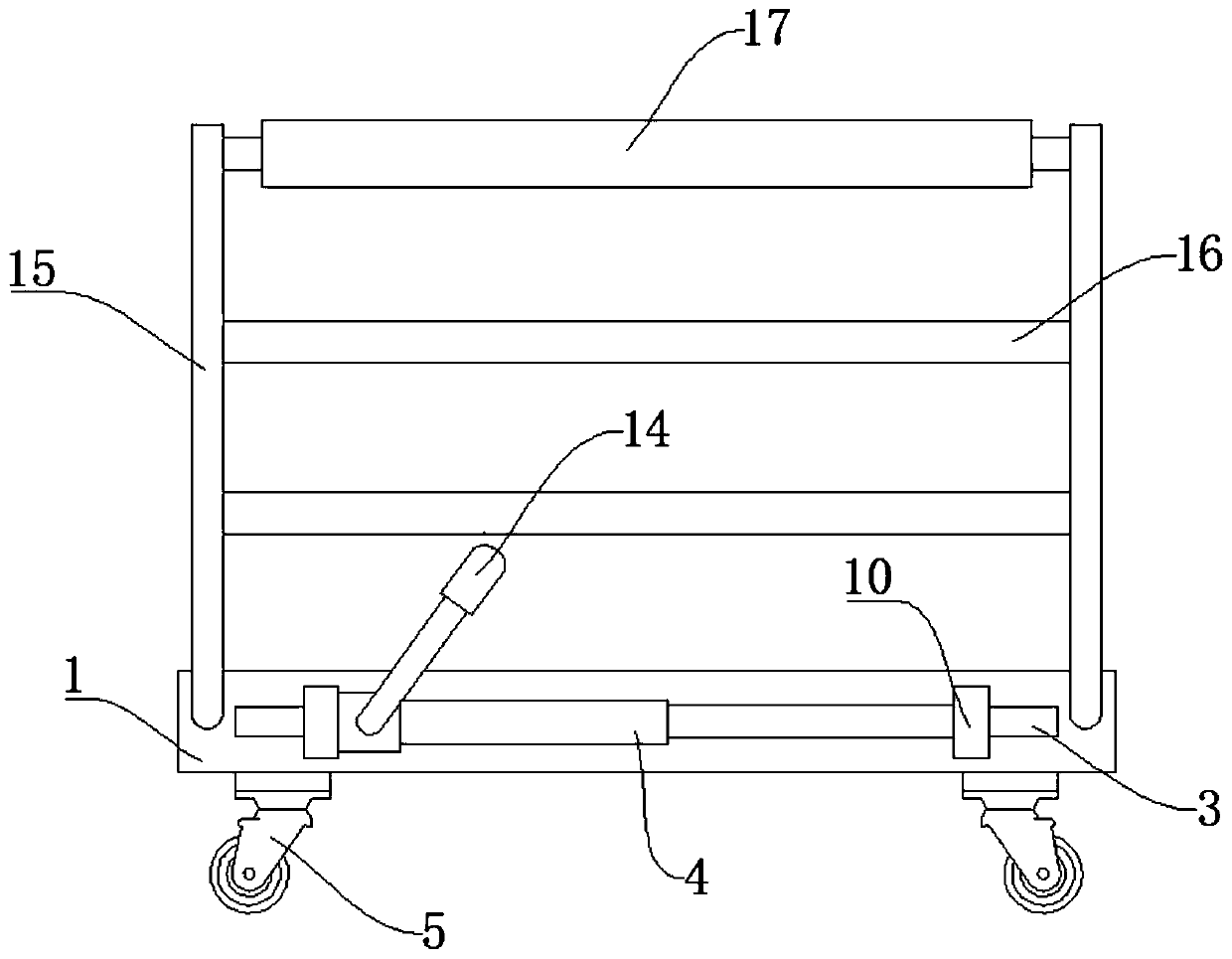

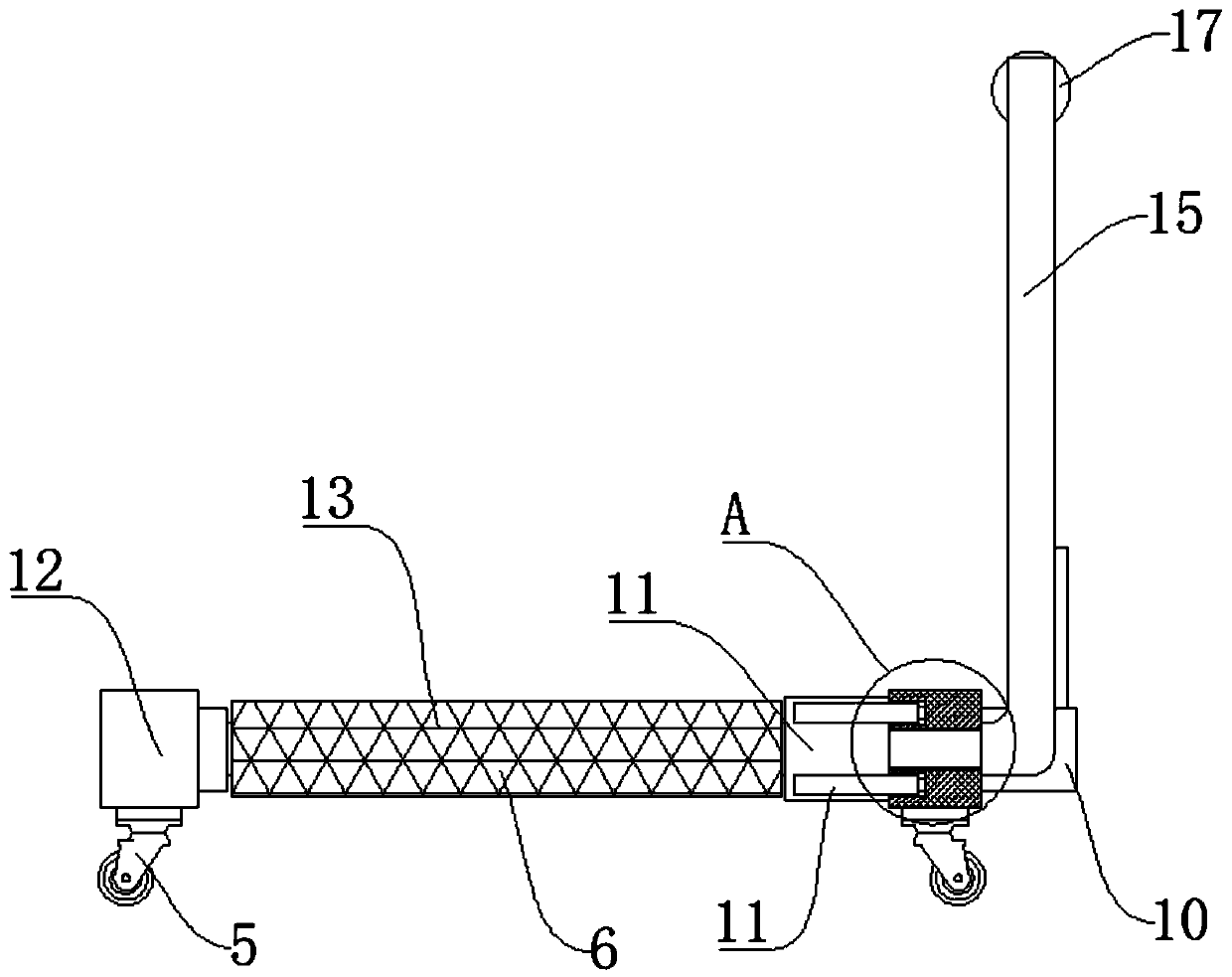

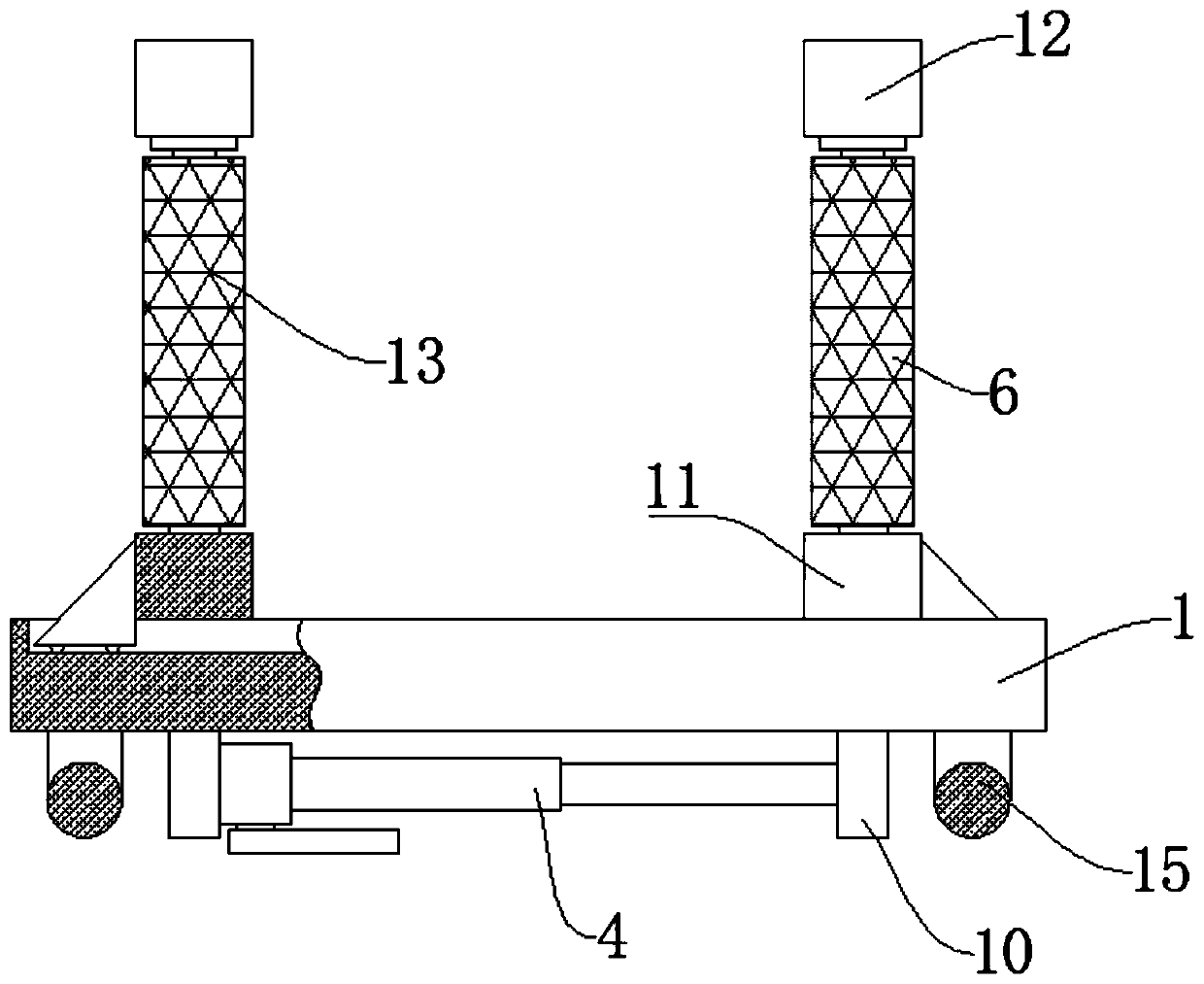

[0018] refer to Figure 1-4 , a bracket for assisting automobile movement, comprising a cross bar 1 and two third connecting blocks 12, a chute 3 is provided inside the cross bar 1, a slider 2 is slidably arranged in the chute 3, and the two ends of the slider 2 The first connecting block 10 and the second connecting block 11 are respectively fixedly welded, and the hydraulic telescopic rod 4 is fixedly connected between the two first connecting blocks 10, and the operation handle of the hydraulic telescopic rod 4 is covered with a non-slip rubber sleeve 14, The roller 6 is connected between the second connecting block 11 and the third connecting block 12 through bearing rotation, and the outer wall of the roller 6 is engraved with cross anti-slip lines 13, and the bottom of the cross bar 1 and the bottom of the third connecting block 12 are fixedly installed There are universal wheels 5, and the number of universal wheels 5 at the bottom of the cross bar 1 is two and symmetri...

Embodiment 2

[0021] refer to Figure 1-3 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the side of the cross bar 1 close to the first connecting block 10 is provided with a protective mechanism, and the protective mechanism includes two fixed welded on the side wall of the cross bar 10 The two right-angle bars 15 are fixedly welded with equidistantly distributed connecting rods 16, and the connecting rod 16 at the top of the right-angle bars 15 is provided with a cylindrical handle 17. The setting of the protective mechanism is to prevent the car from moving. When the corners are touched and damaged, it is also convenient for us to hold the cylindrical handle 17 mobile bracket.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com