Crane suitable for roadway hoisting

A crane and hoisting technology, applied in cranes and other directions, can solve the problems that the lifting height cannot be reached, the maximum lifting height of heavy objects is limited, and the collision and interference between heavy objects and the boom can be achieved. The effect of raising altitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

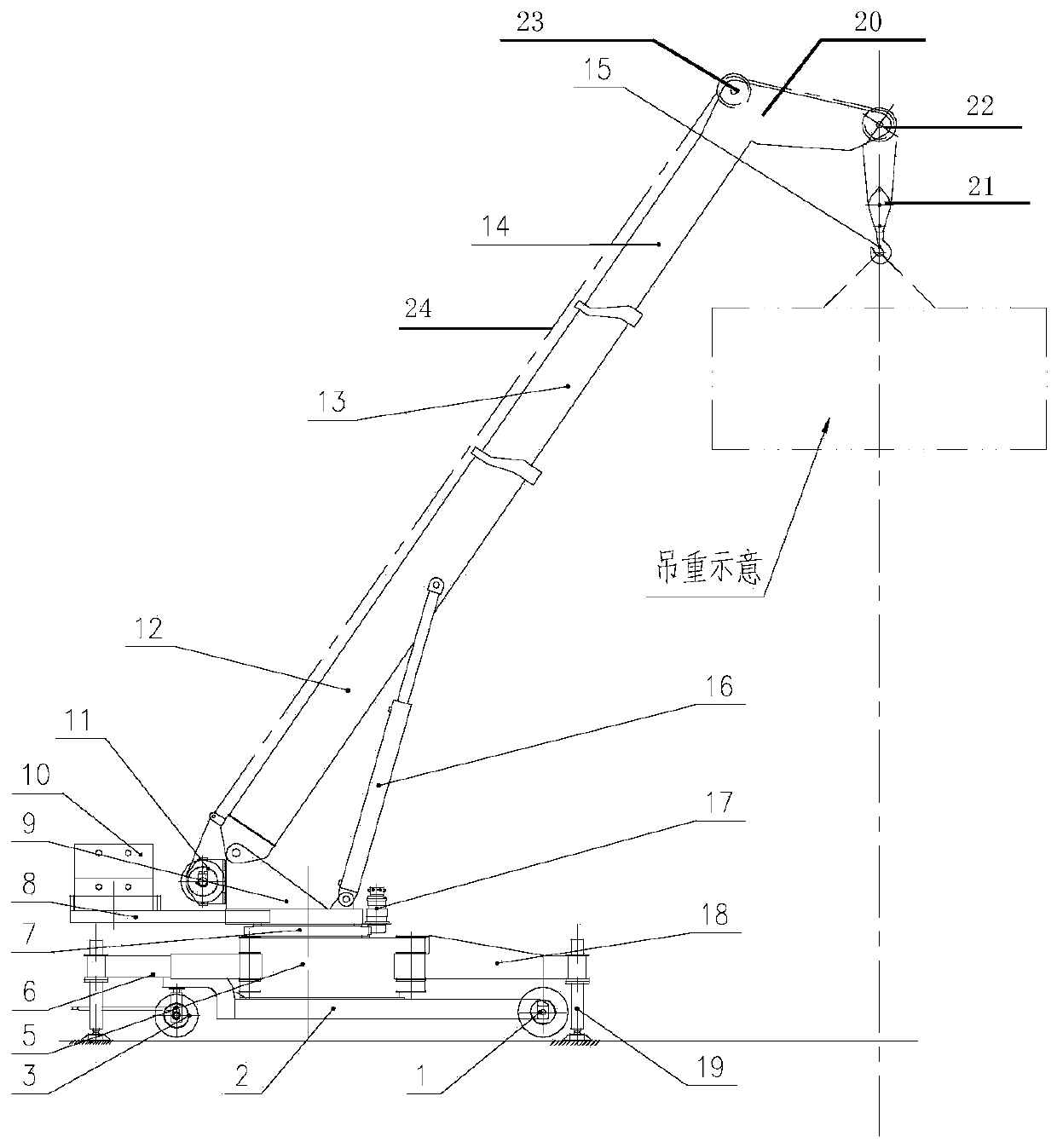

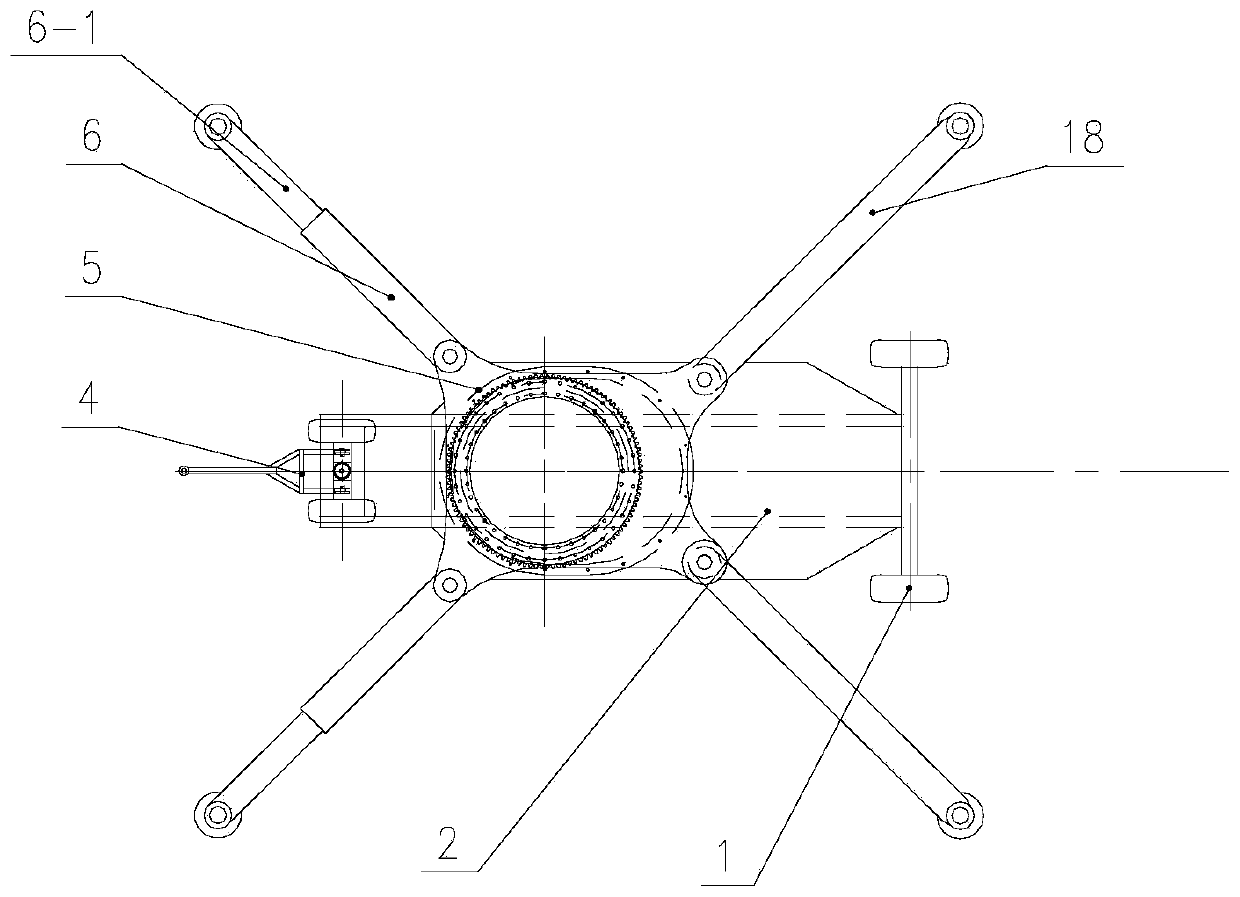

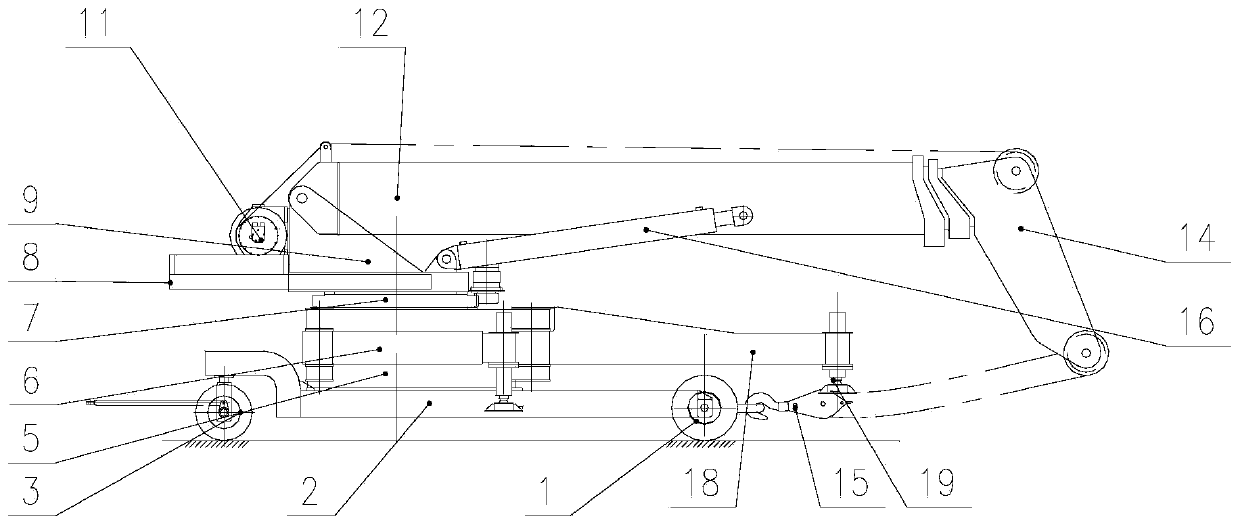

[0023] Such as Figure 1 to Figure 4 As shown, a roadway crane provided by the present invention includes a rear wheel 1, a vehicle frame 2, a front wheel 3, a drawbar 4, a base 5, a front leg 6, a slewing bearing 7, a rear leg 18 and a leg cylinder The part of getting off of 19 forms also comprises the part of getting on the car that is made up of telescoping support 8, turntable 9, counterweight iron 10, winch 11, boom, suspension hook 15, lifting oil cylinder 16 and swing motor 17. The chassis structure composed of pot-shaped base and frame is adopted, and the external structure is small, and it can pass through narrow spaces such as roadways, tunnels, and culverts by being towed by other vehicles; when working, the crane is unfolded, which can provide a large lifting capacity; effectively solves the problem of hanging The problem of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com