Anti-sway device for pull-down crane

A crane and pull-down technology, which is applied in the field of pull-down crane anti-sway devices, can solve the problems of excessive support arm weight and lever arm, single-dimensional anti-sway, and large crane gravity, so as to reduce the difficulty of lifting and reduce the lifting space. Wide and anti-shake effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

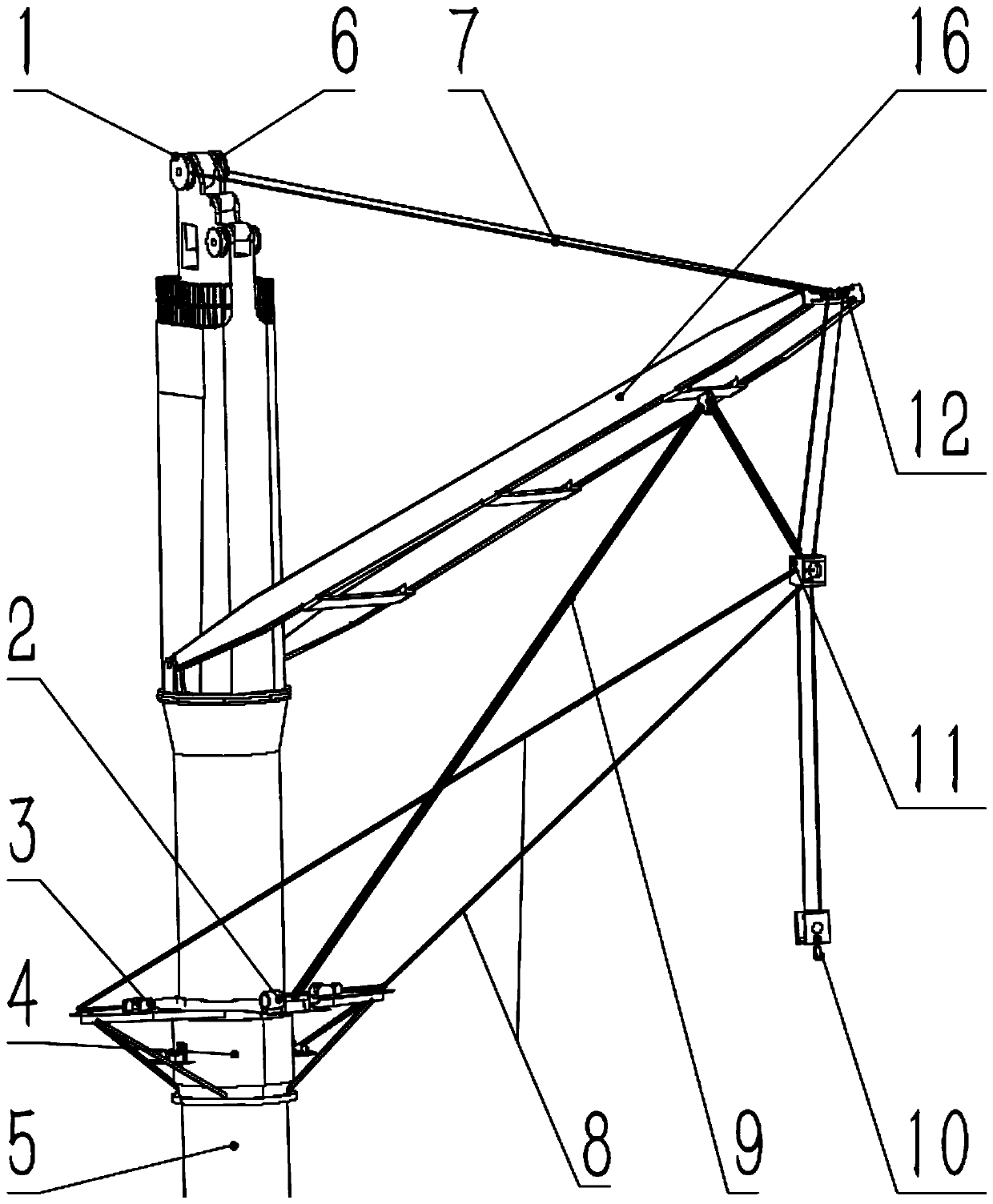

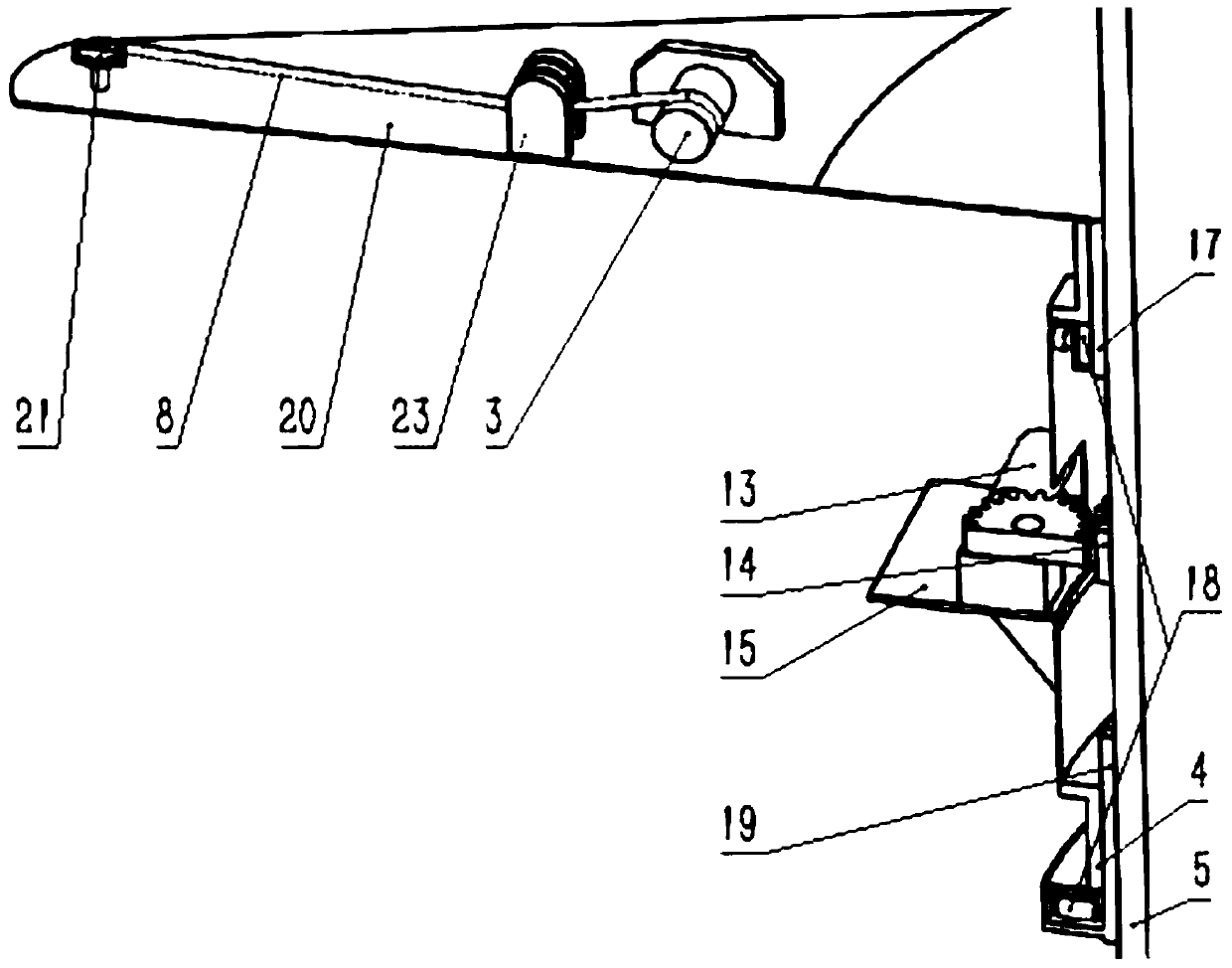

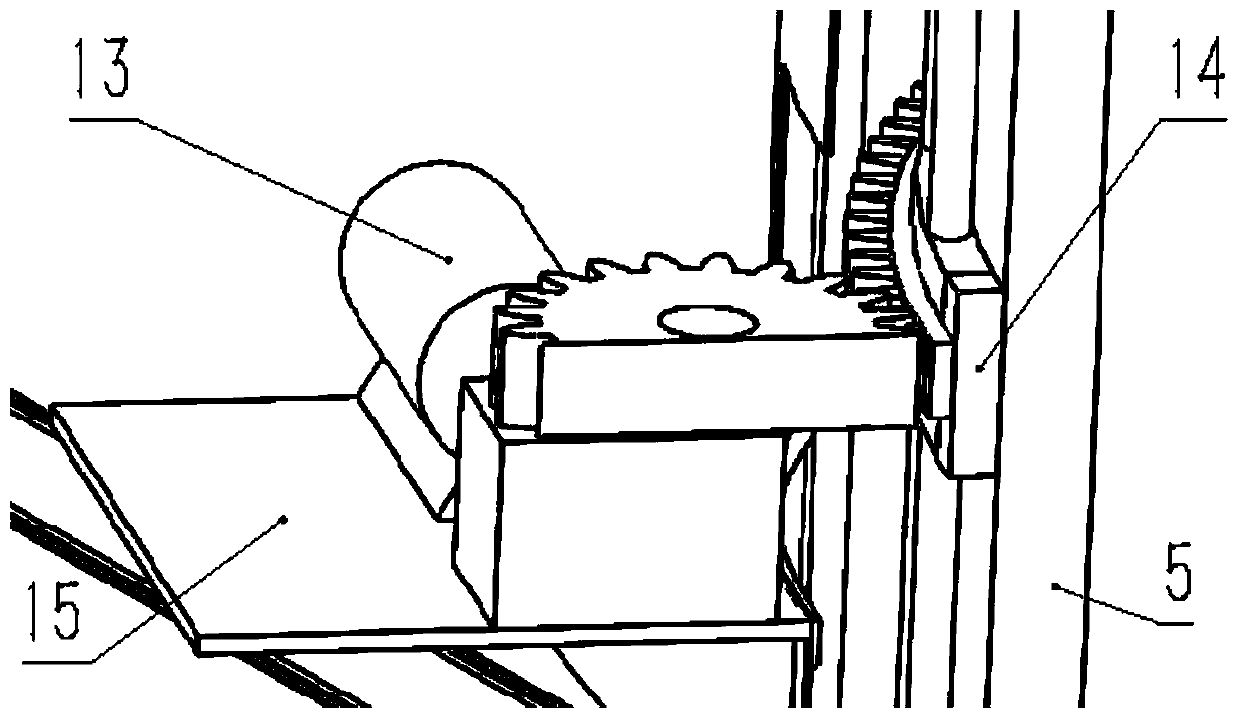

[0031] exist figure 1 and figure 2 In the schematic diagram of the anti-sway device of the pull-down crane shown, the rotating drum device is arranged on the base column 5 of the gram crane, and the base column in the rotating drum 4 is sequentially provided with a set of fixed poles along the circumference of the base column from top to bottom. Connected upper swivel guide rail 17, rotating gear 14 and lower swivel guide rail 19, the upper and lower ends of the drum are provided with upper and lower sets of casters 18 that are respectively pressed against the upper and lower swivel guide rails, and the drum driving device 13 includes a drive Motor and driving gear, wherein the driving motor is fixed on the rotating drum driving device fixing plate 15 on the rotating drum drum wall, the rotating drum drum wall above the rotating drum driving device fixing plate is provided with an opening, and the driving gear is located on the driving motor on the output shaft and meshes wi...

Embodiment 2

[0043] Symmetrically arranged inner and outer two sets of cable mechanisms with the same structure, such as Figure 10 As shown, the cable actuator 24 is located in the middle of the wing-shaped support frame, that is, between the cable drive device 3 and the cable fixed pulley 21, and the lower end of the cylinder barrel of the cable actuator is fixedly connected to the wing-shaped support frame. The upper end of the cylinder is connected with the lower end of the guy wire actuator, and a guy wire actuator pressing pulley is arranged at the upper end of the guy wire actuator, and two guy wire pressure rollers 23 are fixed on both sides of the guy wire actuator cylinder. One end of the dragline 8 is drawn out from the dragline driving device, and the other end respectively goes around the dragline pinch roller, the dragline actuator pinch pulley, another dragline pinch wheel and the dragline fixed pulley, and finally fixes it on the pulley. on a rectangular frame. Other compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com