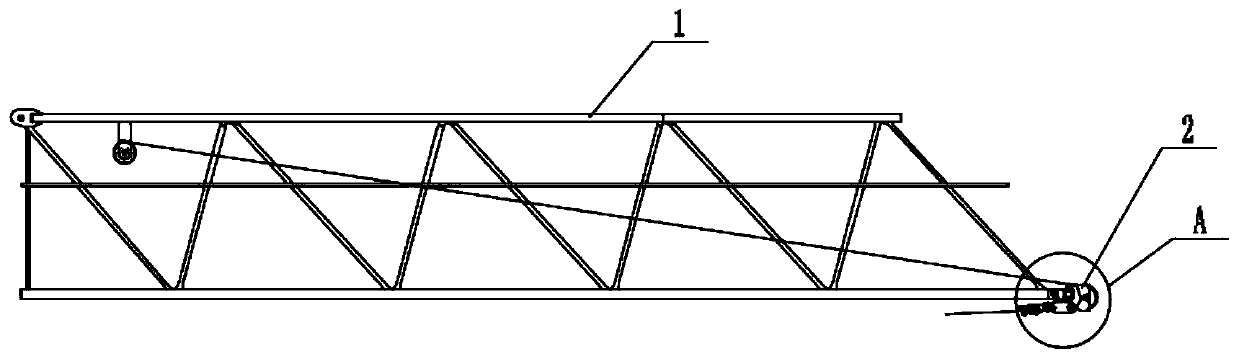

Hoisting jib and hoist

A boom and crane technology, which is applied in the direction of cranes and the like, can solve the problems of the complex connection structure of the boom tip section and the poor versatility, and achieve the effects of increasing the maximum lifting capacity, improving the versatility and simple connection structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

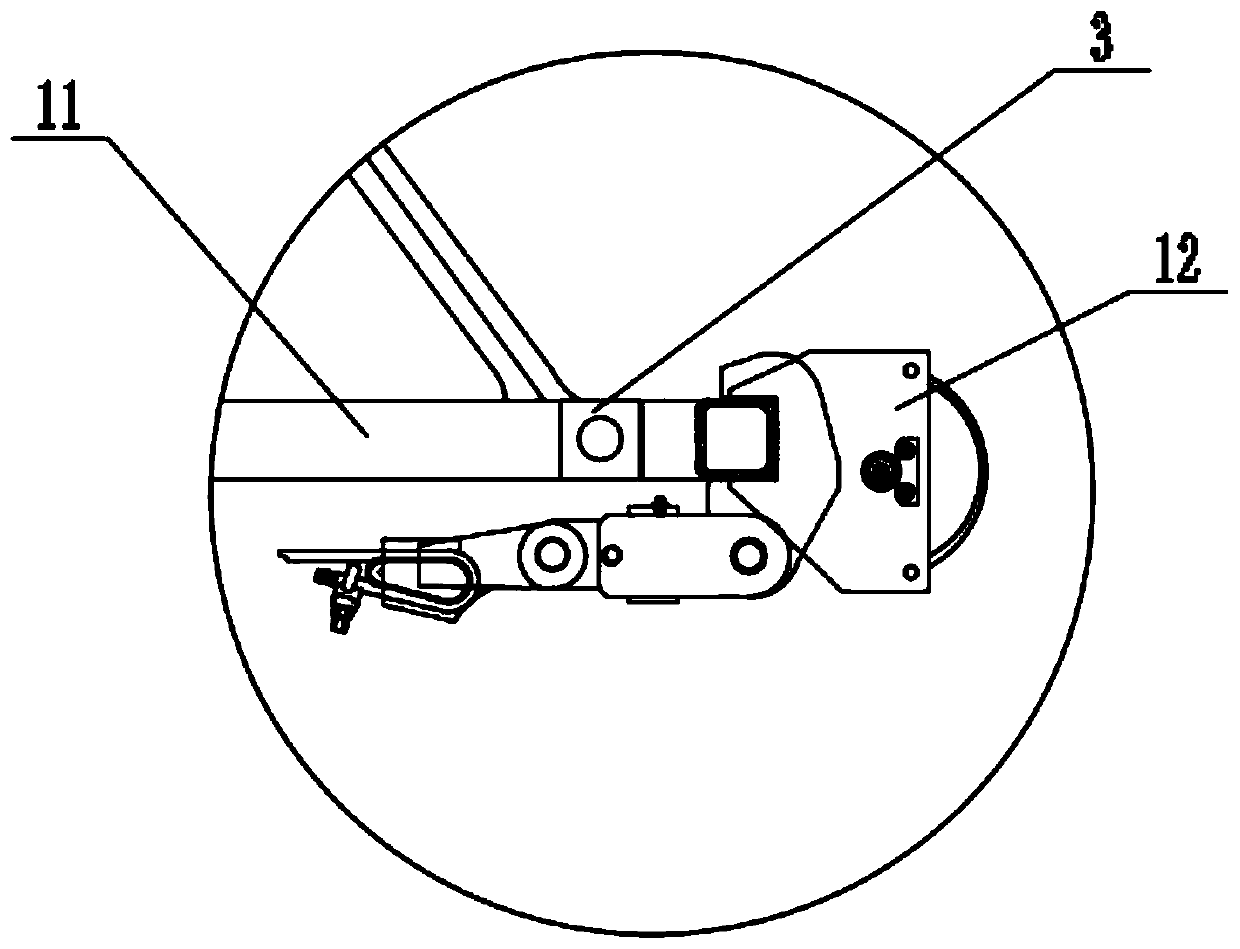

[0048] According to another embodiment of the present invention, one end of the first connecting block 31 is connected to one end of the second connecting block 32 by bolts, and one end of the first connecting block 31 is connected to the second connecting block 32 Corresponding screw holes are respectively provided at one end of each, and the bolts are installed in the screw holes, and the axial direction of the bolts is parallel to the extending direction of the end boom section 1 .

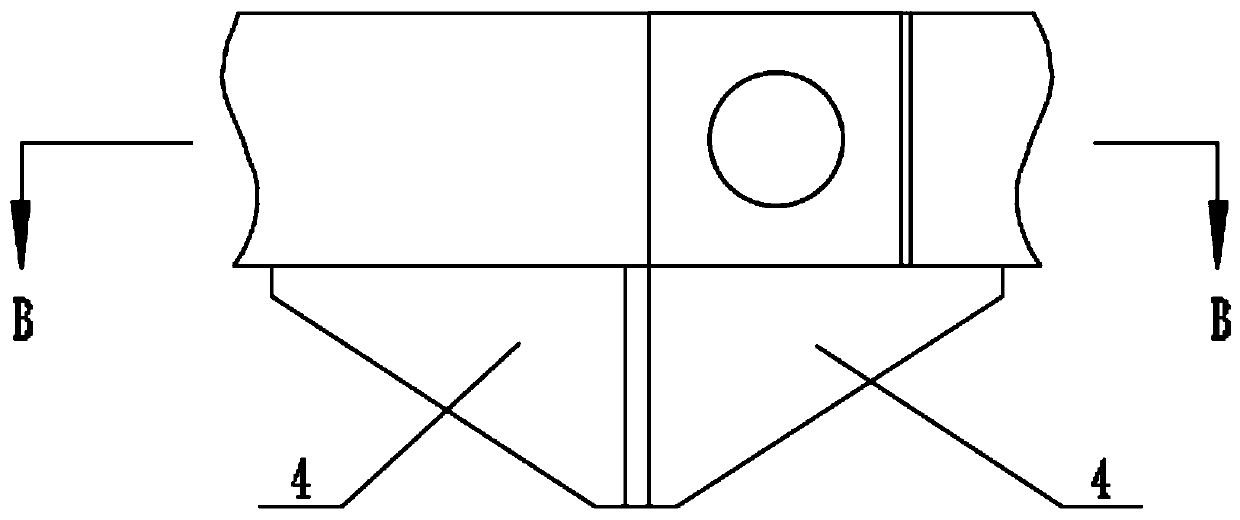

[0049] In order to increase the maximum bending moment that the arm tip section 2 can withstand, according to an embodiment of the present invention, the bottoms of the first connecting block 31 and the second connecting block 32 are respectively provided with reinforcing blocks 4, and the first The reinforcement blocks 4 of the first connection block 31 and the second connection block 32 are in surface contact with each other. Such an arrangement increases the contact area between the first co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com