Vinyl chloride polymerization terminator, its preparation method and application

A vinyl chloride polymerization and terminator technology, which is applied in the field of resin synthesis, can solve the problems of poisonous phenolic antioxidants, etc., and achieve the effects of improving aging whiteness, high termination efficiency, and high whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

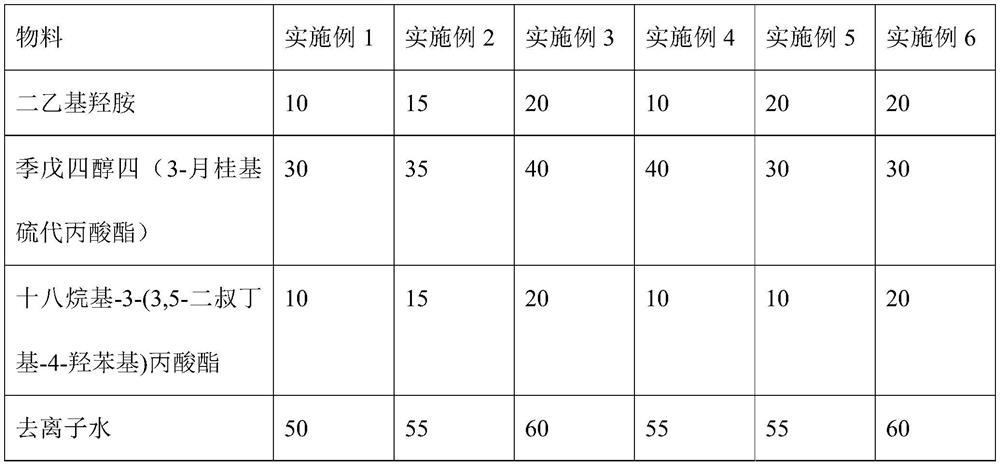

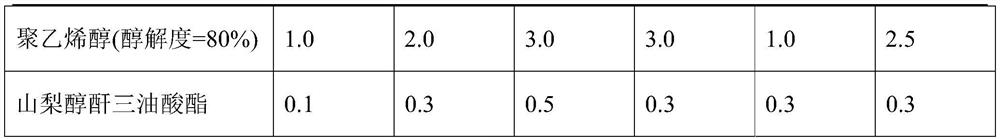

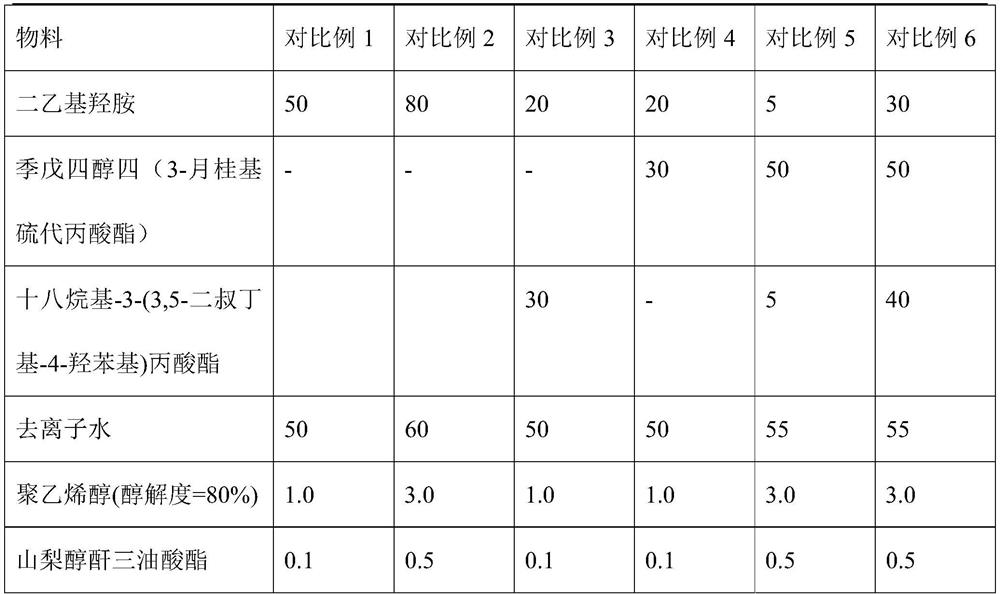

[0021] A vinyl chloride polymerization terminator, the components and contents of Examples 1-5 are shown in Table 1.

[0022] Each material component was weighed according to the proportioning in Table 1. Mix 30~40g of pentaerythritol tetrakis(3-lauryl thiopropionate), 10~20g of octadecyl-3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate, 0.1~ Put 0.5g of sorbitan trioleic acid and 50-60g of deionized water into a 250mL glass beaker, stir and heat to 55°C-60°C, keep it for 10 minutes, then cool down to room temperature 23±2°C. Then add 10-20g diethylhydroxylamine to the glass beaker, 1-3g polyvinyl alcohol () aqueous solution with a degree of polymerization of 350, a degree of alcoholysis of 80%, and a concentration of 5%, stir well and pour into high-speed shear emulsification After emulsifying in the machine at 2000r / min for 30min, a vinyl chloride polymerization terminator in which each component exists uniformly and stably in the emulsion is obtained.

[0023] Table 1

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com