Vinyl chloride polymerization terminator as well as preparation method and application thereof

A technology of vinyl chloride polymerization and terminator, which is applied in the field of vinyl chloride polymerization terminator and preparation, can solve the problems of decreased stabilization effect of terminator and hydrolysis of phosphite stabilizer, and achieves high termination efficiency, excellent transparency, high The effect of transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

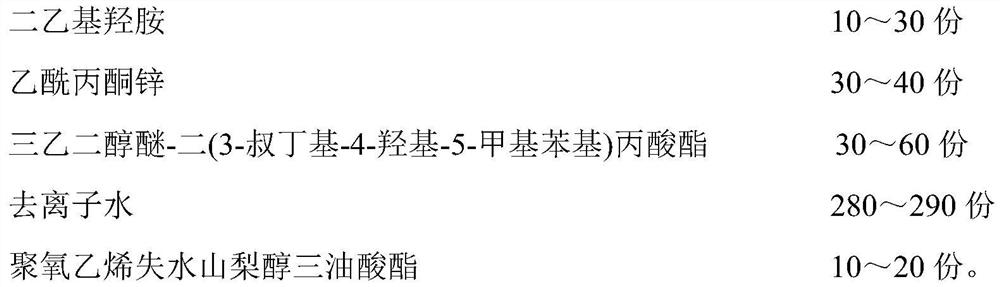

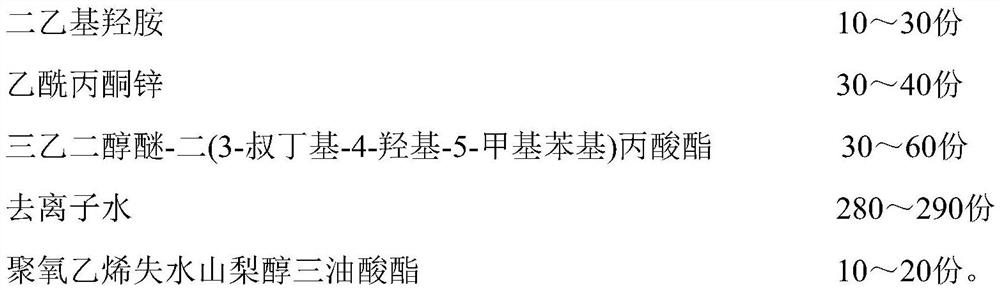

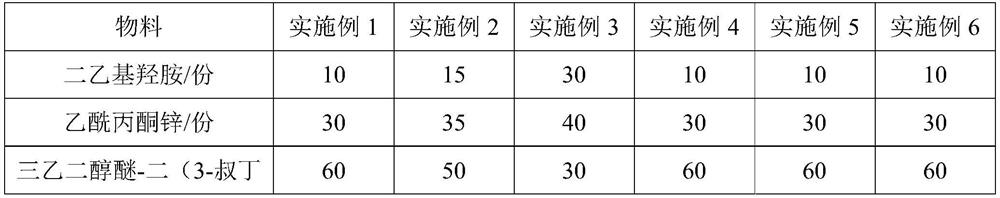

[0022] Vinyl chloride polymerization terminator of the present invention, raw material is made of diethylhydroxylamine, zinc acetylacetonate, triethylene glycol ether-two (3-tert-butyl-4-hydroxyl-5-methylphenyl) propionate , deionized water and emulsifier polyoxyethylene sorbitan trioleate composition; Raw material ratio as shown in table 1.

[0023] The preparation method of vinyl chloride polymerization terminator of the present invention, zinc acetylacetonate, triethylene glycol ether-bis(3-tert-butyl-4-hydroxyl-5-methylphenyl) propionate, deionized water Put it into a glass beaker, stir and heat to 80°C, then add the emulsifier polyoxyethylene sorbitan trioleate into the glass beaker, stir well, pour it into a high-speed shear emulsifier, and emulsify at 2000r / min for 30min , add diethylhydroxylamine, and continue to emulsify uniformly to obtain an environmentally friendly and highly efficient vinyl chloride polymerization terminator in which each component exists uniforml...

Embodiment 2

[0026] The vinyl chloride polymerization terminator of the present invention consists of diethylhydroxylamine, zinc acetylacetonate, triethylene glycol ether-bis(3-tert-butyl-4-hydroxyl-5-methylphenyl) propionate, Composition of deionized water and emulsifier polyoxyethylene sorbitan trioleate; raw material ratio as shown in Table 1.

[0027] The preparation method of vinyl chloride polymerization terminator of the present invention, zinc acetylacetonate, triethylene glycol ether-bis(3-tert-butyl-4-hydroxyl-5-methylphenyl) propionate, deionized water Put it into a glass beaker, stir and heat to 82°C, then add emulsifier polyoxyethylene sorbitan trioleate into the glass beaker, stir evenly, pour it into a high-speed shear emulsifier and emulsify at 2000r / min for 30min , add diethylhydroxylamine, and continue to emulsify uniformly to obtain an environmentally friendly and highly efficient vinyl chloride polymerization terminator in which each component exists uniformly and stabl...

Embodiment 3

[0030] The vinyl chloride polymerization terminator of the present invention consists of diethylhydroxylamine, zinc acetylacetonate, triethylene glycol ether-bis(3-tert-butyl-4-hydroxyl-5-methylphenyl) propionate, Composition of deionized water and emulsifier polyoxyethylene sorbitan trioleate; raw material ratio as shown in Table 1.

[0031]The preparation method of vinyl chloride polymerization terminator of the present invention, zinc acetylacetonate, triethylene glycol ether-bis(3-tert-butyl-4-hydroxyl-5-methylphenyl) propionate, deionized water Put it into a glass beaker, stir and heat to 85°C, then add the emulsifier polyoxyethylene sorbitan trioleate into the glass beaker, stir well, pour it into a high-speed shear emulsifier, and emulsify at 2000r / min for 30min , add diethylhydroxylamine, and continue to emulsify evenly to obtain an environmentally friendly and highly efficient vinyl chloride composite terminator in which each component exists uniformly and stably in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com