Production method of solution polymerized styrene-butadiene rubber with low initiator residue and product

A technology of solution-polymerized styrene-butadiene rubber and a production method, which is applied in the production of bulk chemicals, optimization of rolling resistance, emission reduction of road transportation, etc., can solve the problem of removing the initiator without considering the carbon dioxide inflow treatment device and without considering the termination efficiency. Efficiency and other issues, to achieve the effect of improving termination efficiency and initiator removal rate, improving stability and chromaticity, and prolonging yellowing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

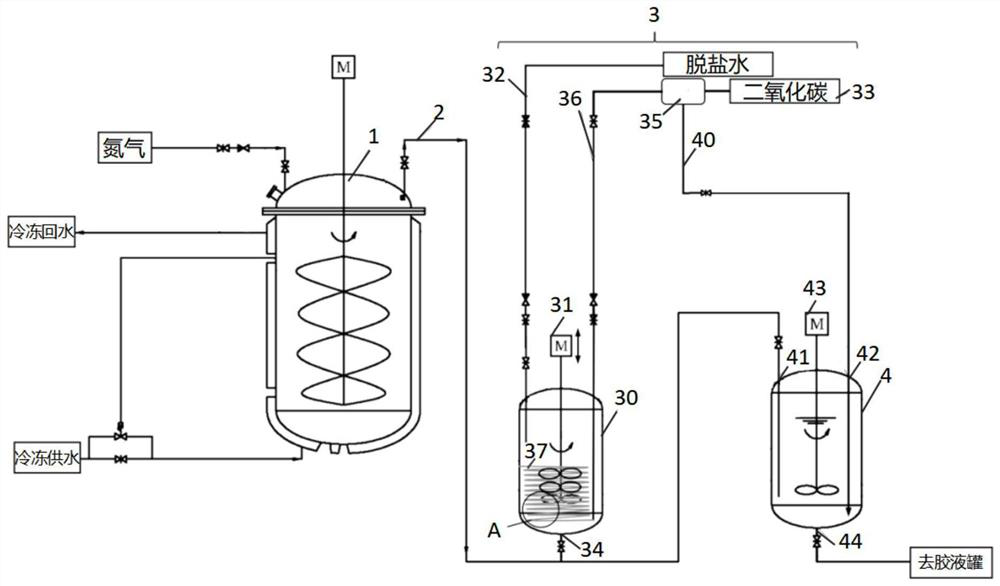

[0050] Under nitrogen protection, 21,000kg of n-hexane, 830kg of styrene and 2,270kg of 1,3-butadiene were added to the reactor, and heated to a specified temperature of 50 °C, followed by adding 30.5 mol of n-butyllithium initiator, and then at 70 °C. The reaction was carried out at ℃ for 15 min, then at a temperature of 90 ℃ for 15 min, and finally at 115 ℃ for 20 min, and the obtained monomer conversion rate was 100%.

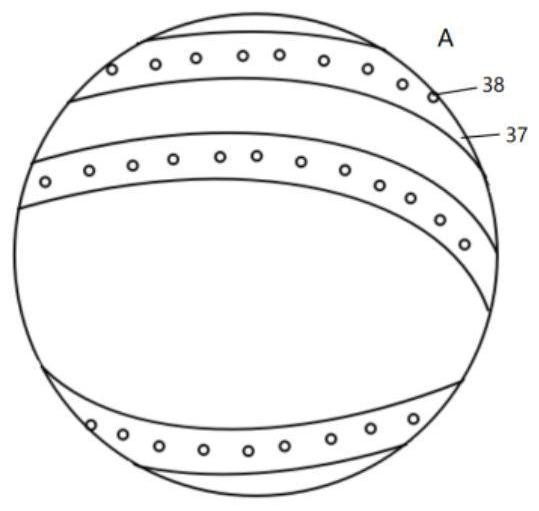

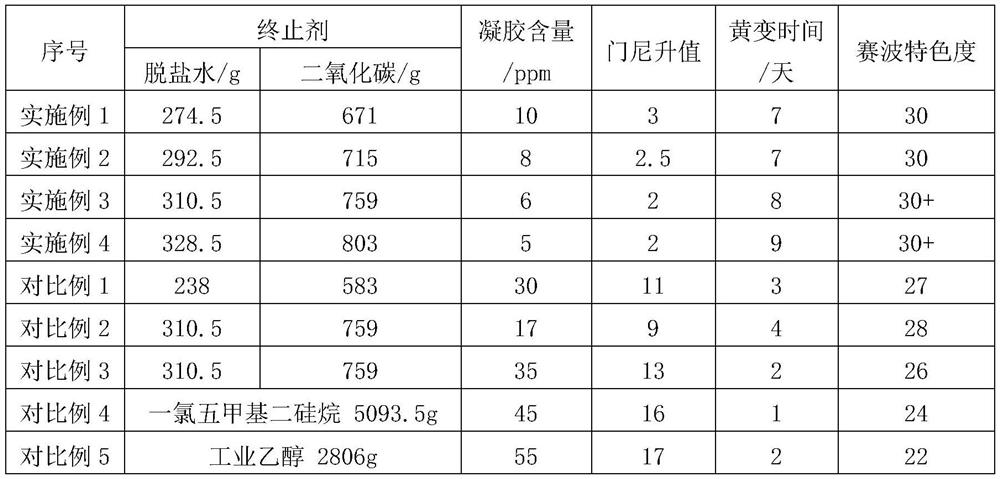

[0051] Embodiment 1-4 adopts desalted water, carbon dioxide to react with Li + to form mixtures in different ratios, where desalinated water, carbon dioxide and Li + The molar ratio of SSBR is greater than or equal to 1:1:2 (the specific dosage is shown in Table 1), to terminate the reaction and precipitate the initiator, fully react in the glue mixing tank and mix evenly to obtain the glue mixture of SSBR rubber , and then agglomerated to obtain SSBR rubber products, and the structure and properties were measured. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com