A double-sided structure weft-knitted cut pile knitted fabric and its weaving method

A technology of double-sided structure and knitted fabrics, which is applied in weft knitting, circular knitting machines with individual moving needles, knitting, etc., which can solve the problems of reducing the diversity of suede fabrics, limiting the scope of application, and easy shedding, etc. problems, to achieve the effect of wide range of use, wide application prospects and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

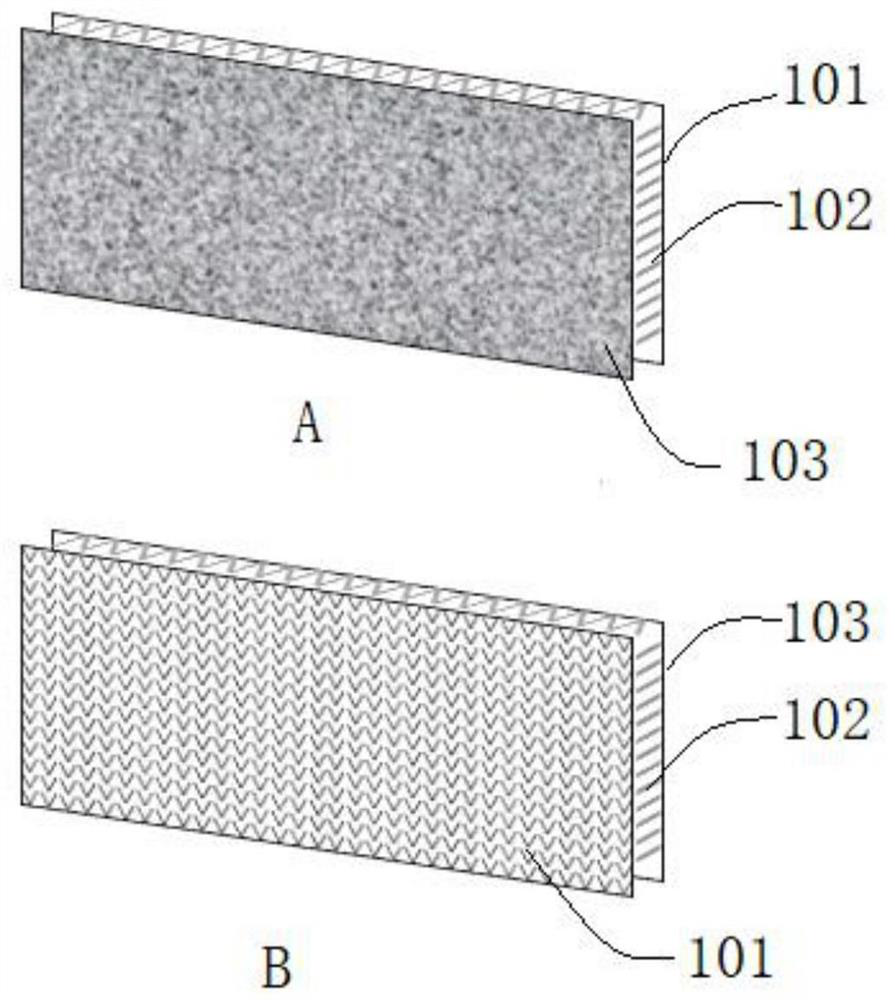

[0037] The structure of the double-sided weft-knitted cut pile knitted fabric woven by the present embodiment is as figure 1 shown.

[0038] In this implementation, the yarn selection specification is:

[0039] 1st way: velvet yarn: 300D / 288F white polyester DTY; ground yarn: 100D / 48F white polyester DTY

[0040] 2nd way: Veil: 100D / 48F white polyester DTY

[0041] The third way: connecting yarn: 50D / 36F white polyester high elastic yarn

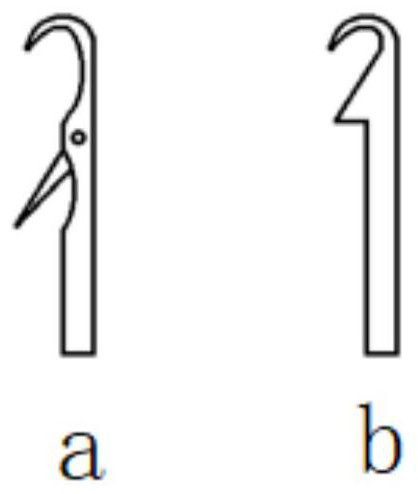

[0042] In this embodiment, the circular knitting machine is set up as follows: circular knitting machine needle cylinder knife needles and needle cylinder latch needles are arranged one by one, and ordinary yarn guides and yarn guides with two yarn guide holes are arranged two by one.

[0043] Circular knitting machine parameters:

[0044] Machine number: 24G / 25.4mm

[0045] Barrel diameter: 30 inches

[0046] Total stitches: 2256

[0047] Number of channels: 54F

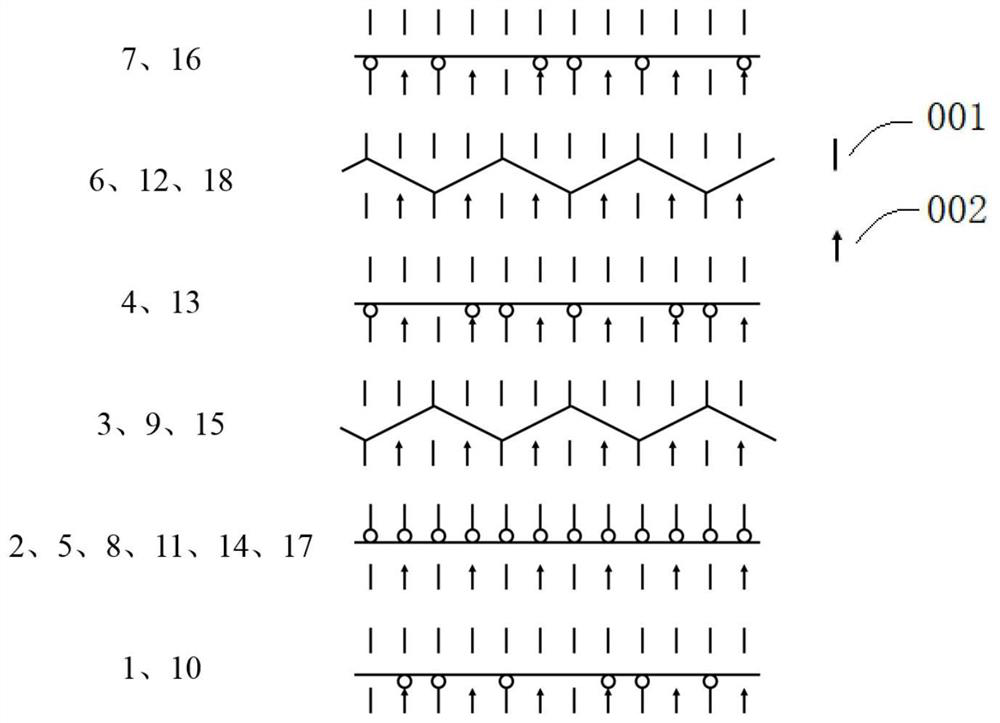

[0048] Such as figure 2 As shown, the weaving method in this implem...

Embodiment 2

[0052] The structure of the double-sided weft-knitted cut pile knitted fabric woven by the present embodiment is as figure 1 shown.

[0053] In this implementation, the yarn selection specification is:

[0054] 1st way: velvet yarn: 600D / 288F black nylon DTY; ground yarn: 150D / 72F black nylon DTY

[0055] The 2nd way: Veil: 150D / 72F white nylon DTY

[0056] The third way: connecting yarn: 50D / 36F white polyester high elastic yarn

[0057] In this embodiment, the circular knitting machine is set up as follows: circular knitting machine needle cylinder knife needles and needle cylinder latch needles are arranged one by one, and ordinary yarn guides and yarn guides with two yarn guide holes are arranged two by one.

[0058] Circular knitting machine parameters:

[0059] Machine number: 24G / 25.4mm

[0060] Barrel diameter: 30 inches

[0061] Total stitches: 2256

[0062] Number of channels: 54F

[0063] Such as Figure 6 As shown, the weaving method in this implementation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com