Bamboo cane surface defect detection method based on triple loss network

A defect detection and bamboo strip technology, applied in image data processing, instruments, calculations, etc., can solve problems such as insufficient detection accuracy, long time consumption, and inability to achieve real-time detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

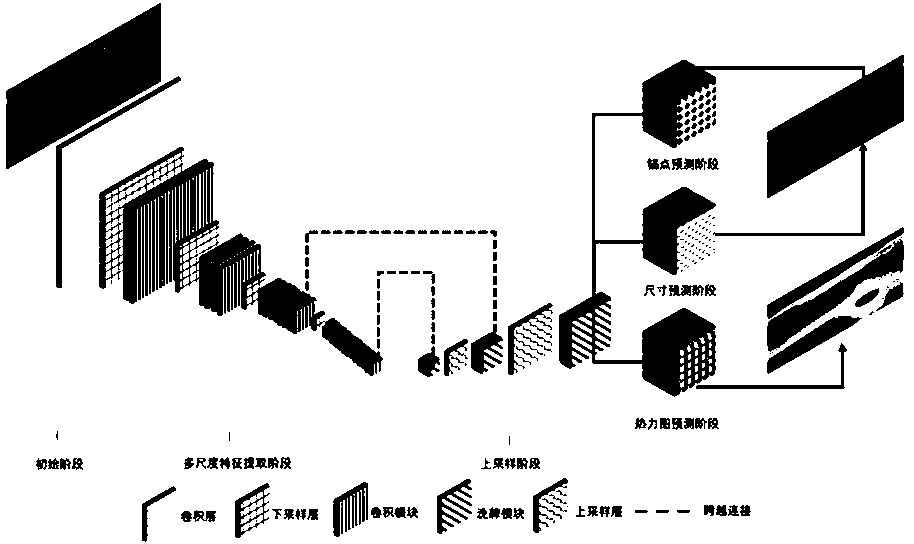

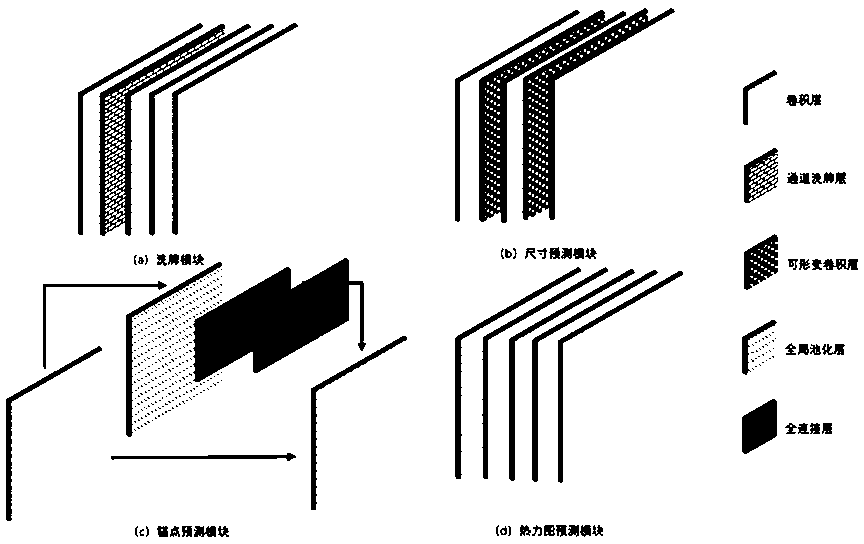

[0069] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

[0070] The invention provides a method for detecting defects on the surface of bamboo strips based on a triple loss network, comprising the steps of:

[0071] Step S1, collecting surface defect data of bamboo strips through a camera installed on the bamboo strip sorting robot to form a data set of bamboo strip surface defects;

[0072] Step S2, training phase: the image I(x) in the bamboo strip surface defect data set is trained by a triple loss network to obtain an anchor point prediction matrix, a size prediction matrix and a heat map prediction matrix;

[0073] Step S3, calculating the loss of the anchor point prediction matrix, the loss of the size prediction matrix and the loss of the heatmap prediction matrix to obtain the total loss of the triple loss network update;

[0074] Step S4, based on the updated total loss of the triple ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com