Gear pitch circle clamping jaw structure

A technology of round claws and gear pitches, which is applied in the field of gear pitch circular claw structures, can solve the problems of easy slipping of gears, easy slipping, and insufficient fixation, and achieve stable gears and turbines, and stable fixation of gears and turbines Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

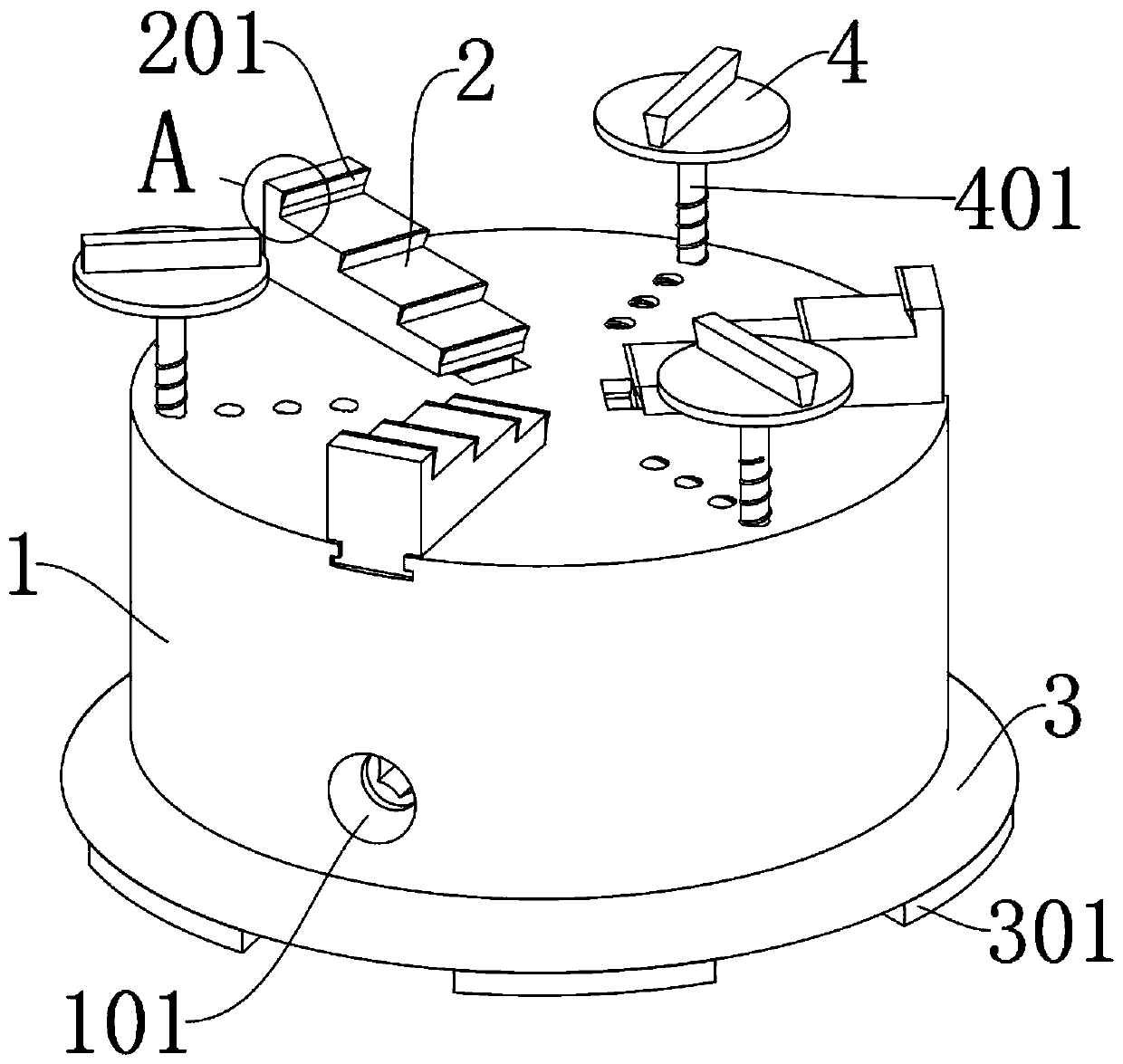

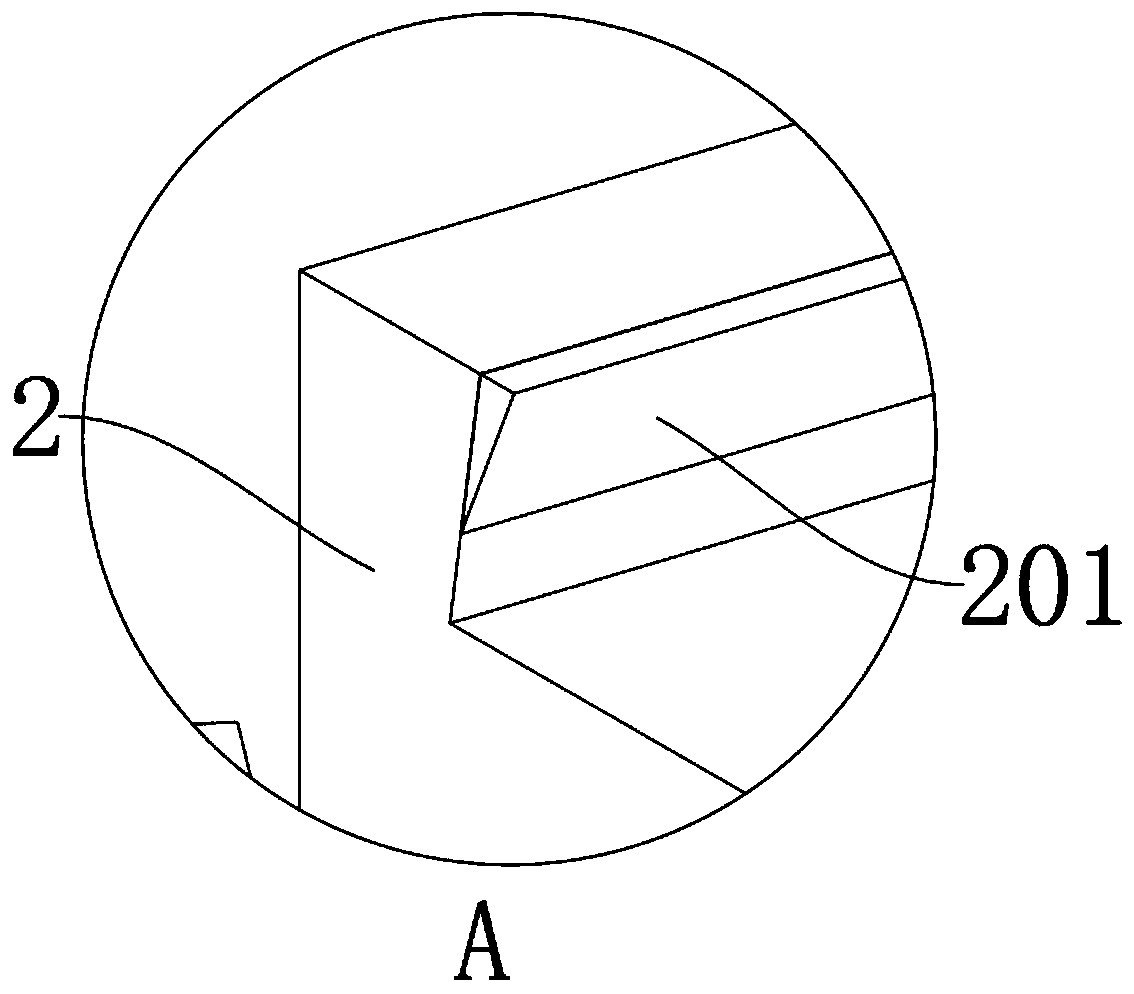

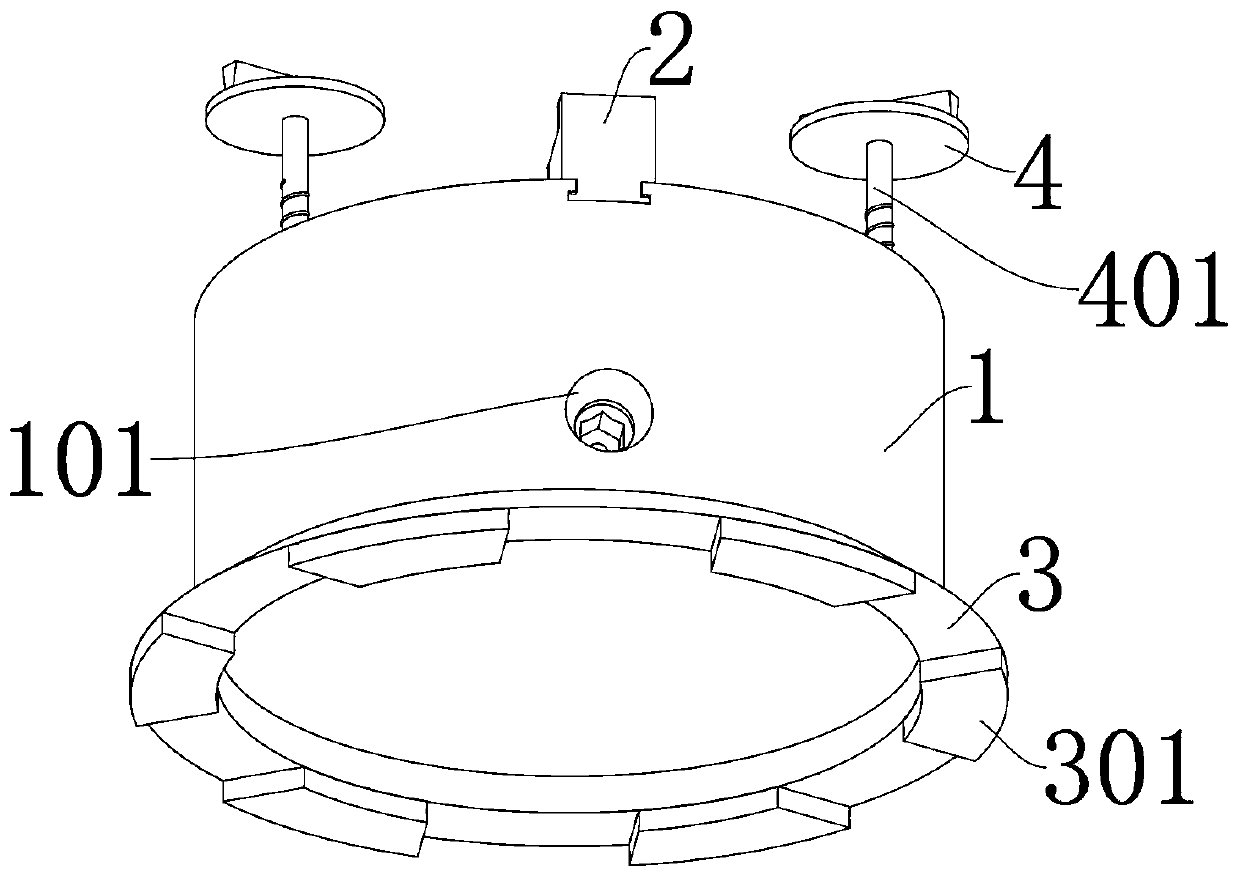

[0027] as attached figure 1 to attach Figure 5 Shown:

[0028]The present invention provides a claw structure of a gear pitch circle, comprising a main body 1, a moving part 2, a side part 3 and a rotating part 4; the main body 1 is a cylindrical structure, and the top of the main body 1 is provided with a connecting groove; There are several threaded holes in different positions, and the outside of the hexagonal socket inside the clamping hole 101 is an inclined structure, which will also play the same role as the clamping hole 101; the moving part 2 is installed inside the connecting groove at the top of the main body 1, and the main body 1 is a rectangular structure, and the rubber contact piece 201 is used to directly contact the gear and the turbine, so that the rubber contact piece 201 can play an anti-slip effect, making the gear and the turbine more stable; the side piece 3 The top end is connected to the bottom of the main body 1 through a fixed connection, and a g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com