Profile cutting device

A technology for cutting devices and profiles, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of uncontrollable straightness, high labor intensity, poor free straightness, etc., and achieve low cost and low labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

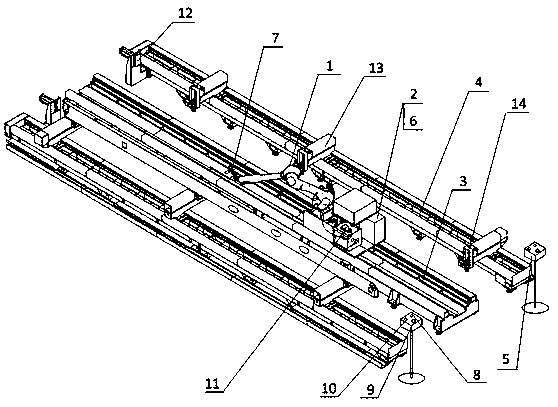

[0016] Such as figure 1 As shown, a profile cutting device includes a robot body 1, a cutting system 2, a robot walking mechanism 3, a cutting platform 4, and a hand control box 5;

[0017] The robot body 1 is a 6-axis multi-joint cutting robot, which is connected to the robot teaching device 11 through a data cable. The robot teaching device 11 is a matching product of the robot body 1, and adopts the common WINDOWS CE system on the market; the robot teaching device There are shortcut menus and instructions inside the 11. The instructions include start straight line, midpoint straight line, end straight line, start arc, midpoint arc, end arc, and empty straight line; The action buttons of each axis of the multi-joint cutting robot are used to adjust the posture of the robot body 1 to achieve the best cutting posture. Input the start straight l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com