Supporting structure and construction method for axillary formwork

A technology of axillary formwork and support structure, which is applied to the connection of formwork/formwork/work frame, building structure, and on-site preparation of building components, which can solve problems such as difficulty in supporting formwork at axillary angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

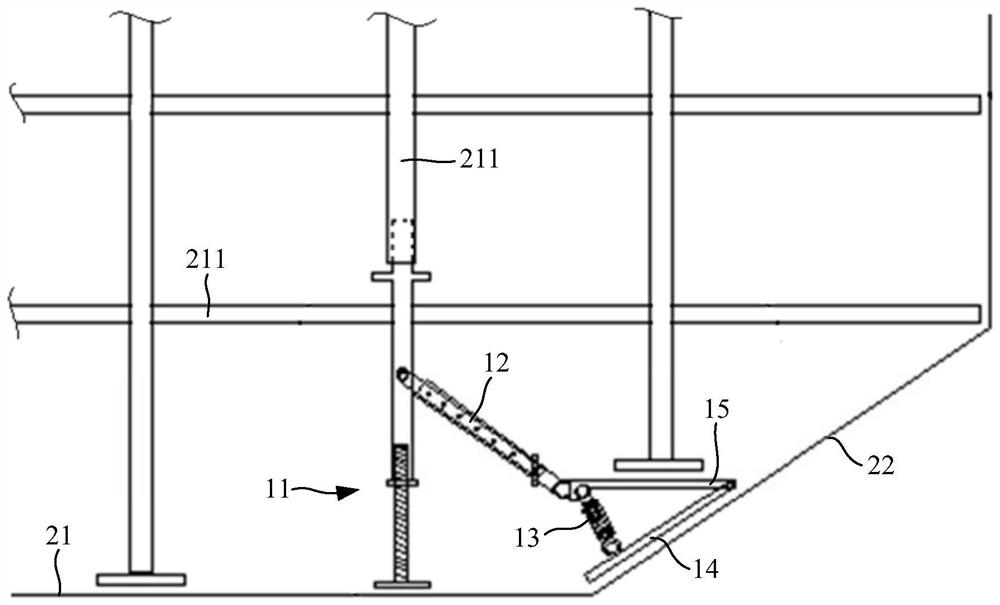

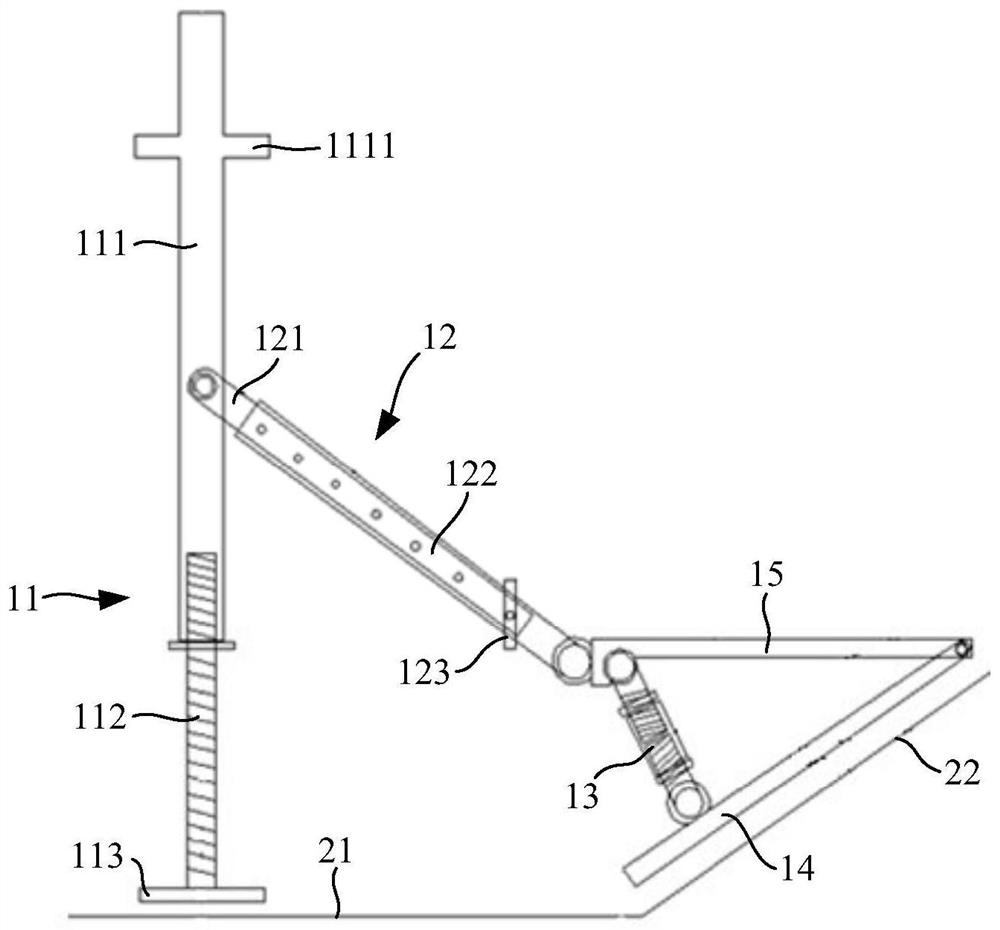

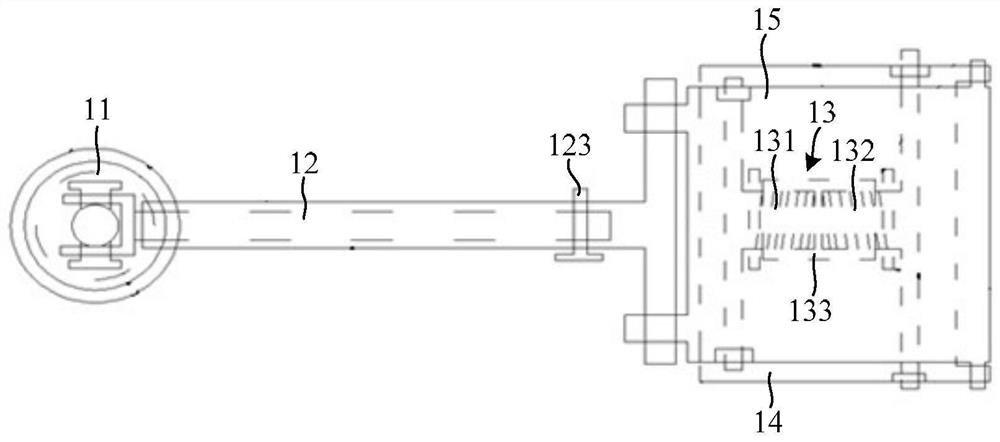

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0029] The present invention adopts a supporting structure for the axillary formwork, by installing the connecting piece on the formwork support near the axillary formwork, and then adjusting the angle of the support plate to match the inclination of the axillary formwork, and then adjusting the telescopic The length of the parts makes the support plate withstand the formwork at the axillary corners. At this time, the bearing plate is horizontal, and formwork supports can be set on the bearing plate to further push the formwork at the axillary corners, which solves the problem of difficult support of the formwork at the axillary corners. According to The actual size of the axillary angle to be formed adjusts the support structure, has good adaptability, improves construction efficiency, is reusable, and can ensure construction quality. The supp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap