Method and control system for monitoring automation system

A technology of automation system and control system, which is applied in the field of automation system, can solve the problems of image display size limitation, difficult user, heavy burden, etc., and achieve the effects of flexible and complete reproduction, intuitive navigation, and easy recognition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

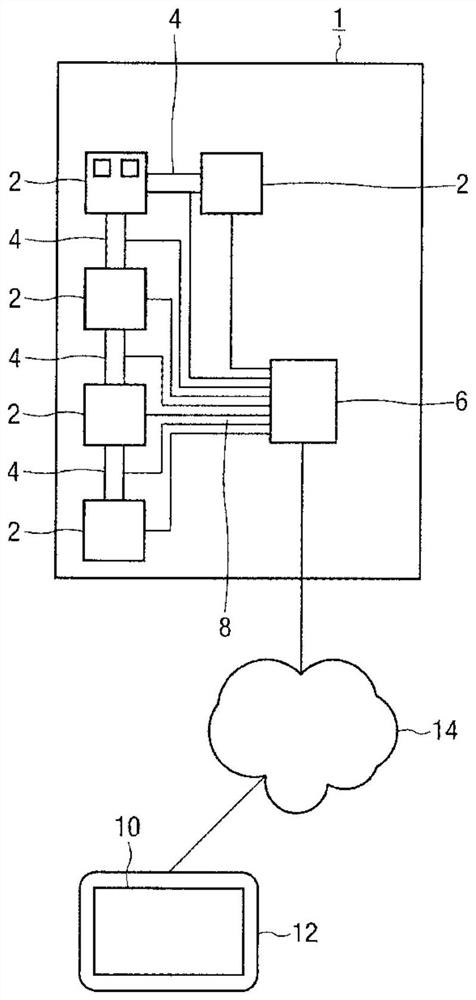

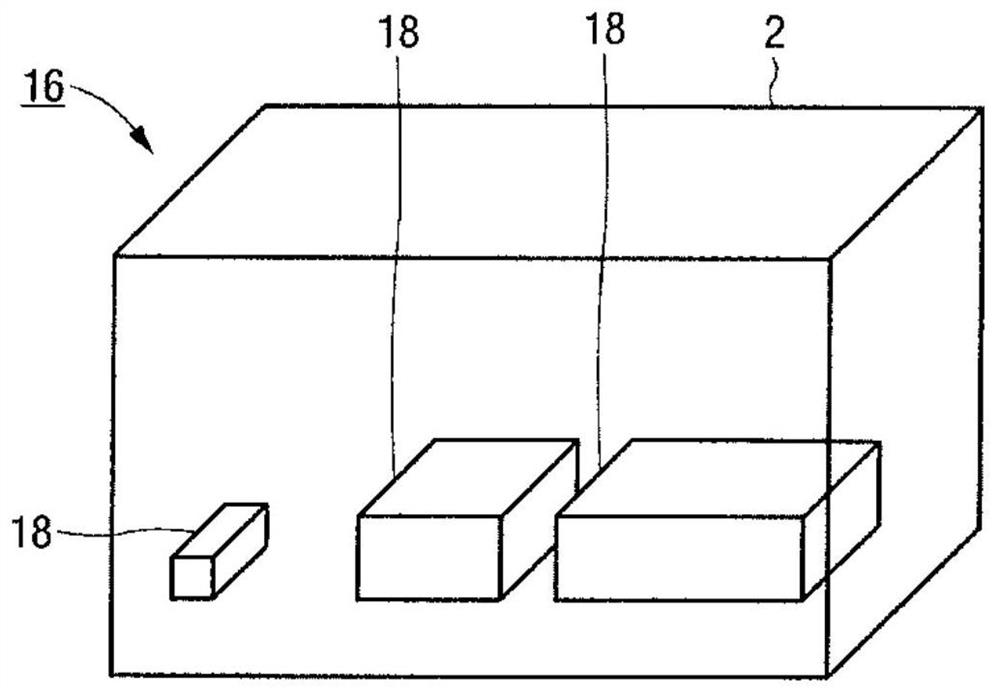

[0039] figure 1 An automated plant 1 is schematically represented, ie an industrial plant in which production steps and processing steps are automated. The industrial plant comprises a large number of components, including a processing station 2 to which the product to be processed or its primary table is transported. This is done by means of conveying means 4, such as conveyor belts.

[0040] The control and monitoring of the automation plant 1 is carried out in the control system 6 , the processing sequence is monitored and, if necessary, influenced by corresponding data from the automation plant 1 with the cooperation of the user. For this purpose, the control system 6 has one or more devices or data connections to devices on the various components 2, components 4 of the automation system 1 for measurement, adjustment, control, display, alarm, recording, exchange or calculation Item 8.

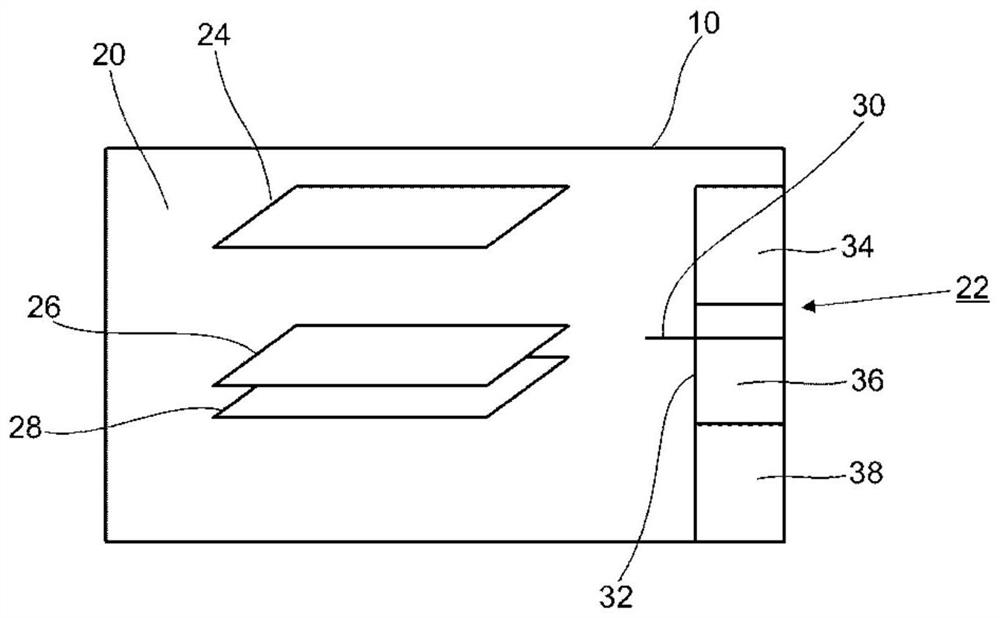

[0041] In the embodiment designed as a screen on the mobile unit 12 , the display of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com