Overprinting method, device, system and computer-readable medium of unit-type flexo printing machine

A unit type, flexo printing machine technology, applied in printing devices, computer parts, calculations, etc., can solve the problem of inability to detect the deviation of the printing plate roller perpendicular to the paper feeding direction, poor quality of printed products, and inability to achieve automatic overprinting And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

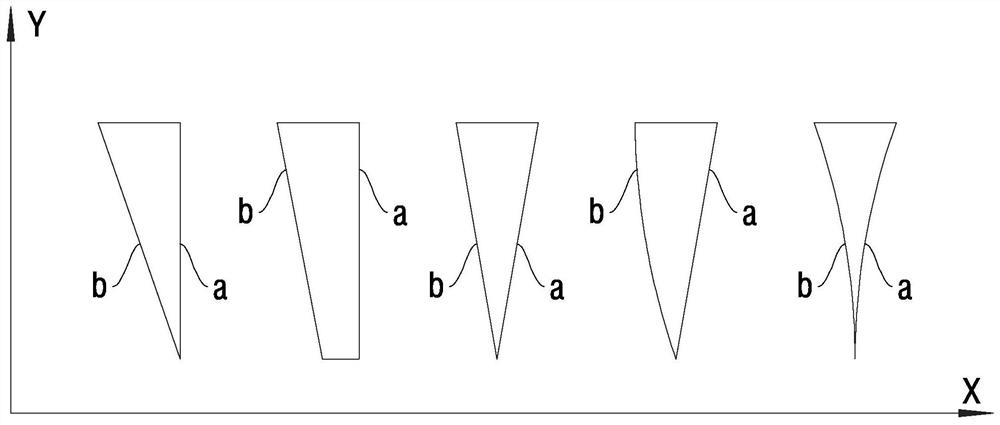

[0111] As mentioned above, in the current overprinting method of the unit-type flexo printing machine, each printing unit included in the unit-type flexo printing machine prints a monochrome square mark on the printing material, according to the distance between each monochrome square mark on the printing material. The distance can determine the position deviation of the printing plate roller in each printing unit in the longitudinal direction (paper-feeding direction), and then adjust the position of the printing plate roller in each printing unit in the longitudinal direction according to the determined position deviation, so as to realize the longitudinal Auto Overprint on . However, according to each single-color square mark, only the positional deviation of the printing plate roller in each printing unit in the longitudinal direction can be determined, but the position of the printing plate roller in each printing unit in the transverse direction (the direction perpendicul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com