Yarn winding device for textile

A winding device and yarn technology, applied in the direction of transportation and packaging, thin material handling, and delivery of filamentous materials, etc., can solve problems such as broken wires, affecting production efficiency, and difficult to find, so as to prevent idling, reduce production costs, The effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

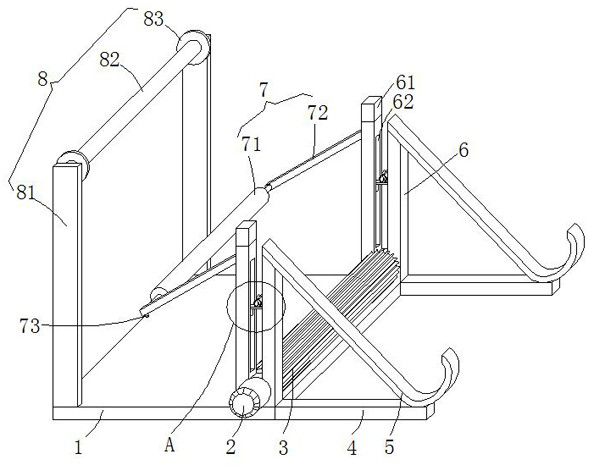

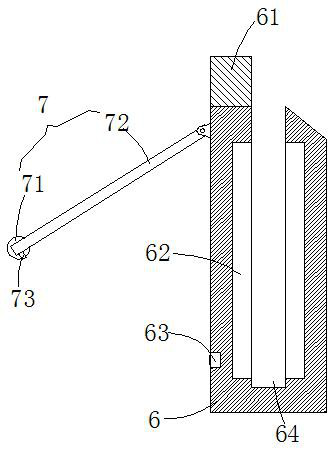

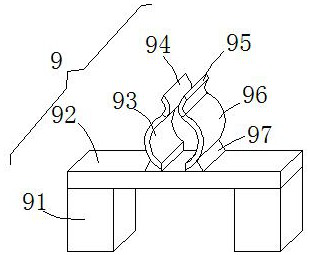

[0030] see Figure 1-5 , the present embodiment provides a yarn winding device for textiles, comprising a base 1 and two emergency stop mechanisms 9, the front and rear ends of the top surface of the base 1 are vertically welded with a support frame 6, and the left end of the front support frame 6 is A limit switch 63 is embedded in the bottom of the surface, and the signal output port of the limit switch 63 is connected with a data processing module 10, and a transmission roller 3 is arranged between the bottom of the opposite side wall of the two support frames 6, and the bottom of the front end of the front support frame 6 A motor 2 is provided, and the motor 2 runs through the side wall of the front side support frame 6 through the rotation of the power shaft, and is connected with the front end surface of the transmission roller 3. The middle positions of the two support frames 6 are provided with a rectangular placement gap 64, and the two rectangular placement gaps The ...

Embodiment 2

[0039] see Figure 1-5 , further improvements have been made on the basis of Example 1:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com