Control method of zero cold water gas water heater and zero cold water gas water heater

A technology of a gas water heater and a control method, which is applied to fluid heaters, lighting and heating equipment, etc., and can solve problems such as gas water heaters being turned on by mistake, and achieve the effect of solving wrong turns on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

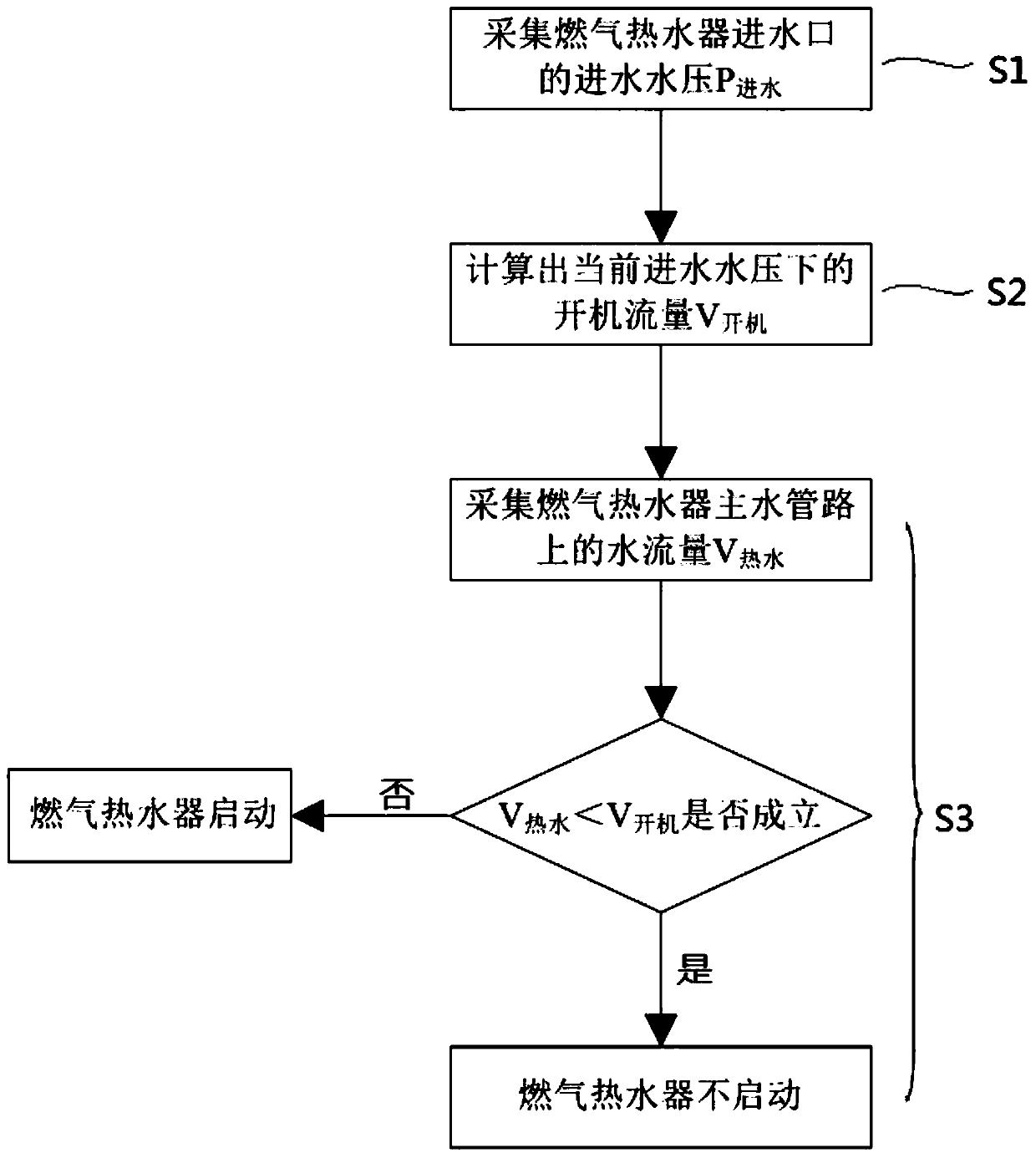

[0035] Embodiment 1 of the present invention provides a control method for a zero-cooled gas water heater, such as Figure 1-2 As shown, it is used to prevent the gas water heater from being turned on by mistake, and the specific implementation is as follows:

[0036] S1, real-time collection of the water inlet water pressure P of the water inlet of the gas water heater 进水 ;

[0037] Specifically, it is detected by a water pressure sensor arranged at the water inlet of the gas water heater;

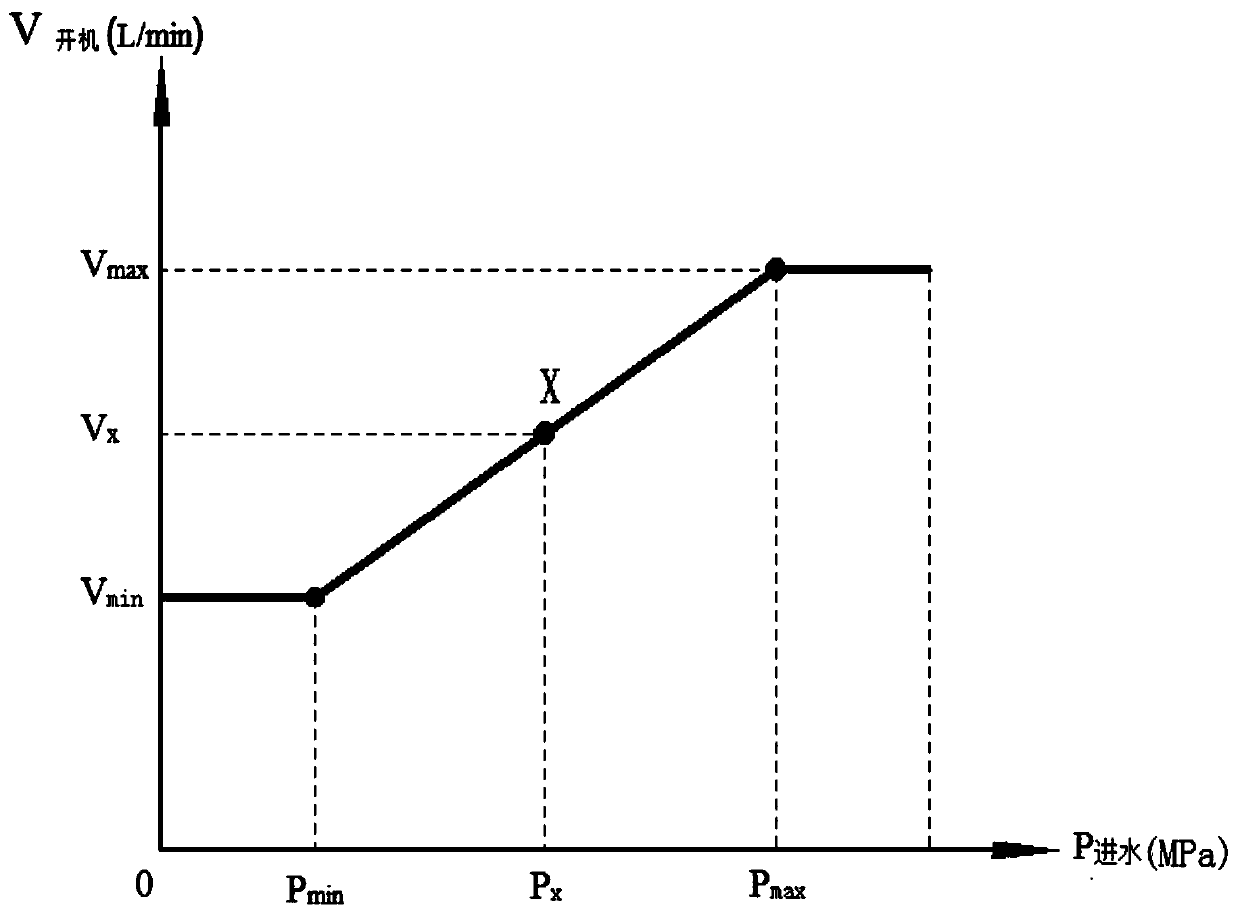

[0038] S2, the inlet water pressure P in the S1 进水 Match the preset gas water heater start-up flow, and calculate the start-up flow V under the current water inlet pressure 开机 ;

[0039] Specifically, according to the inlet water pressure P 进水 and water pressure minimum P min and the maximum water pressure P max The relationship between the power-on flow V 开机 :

[0040] When P 进水 ≤P min when V 开机 =V min ;

[0041] When P 进水 ≥P max when V 开机 =V max ;

[0042] When P min...

Embodiment 2

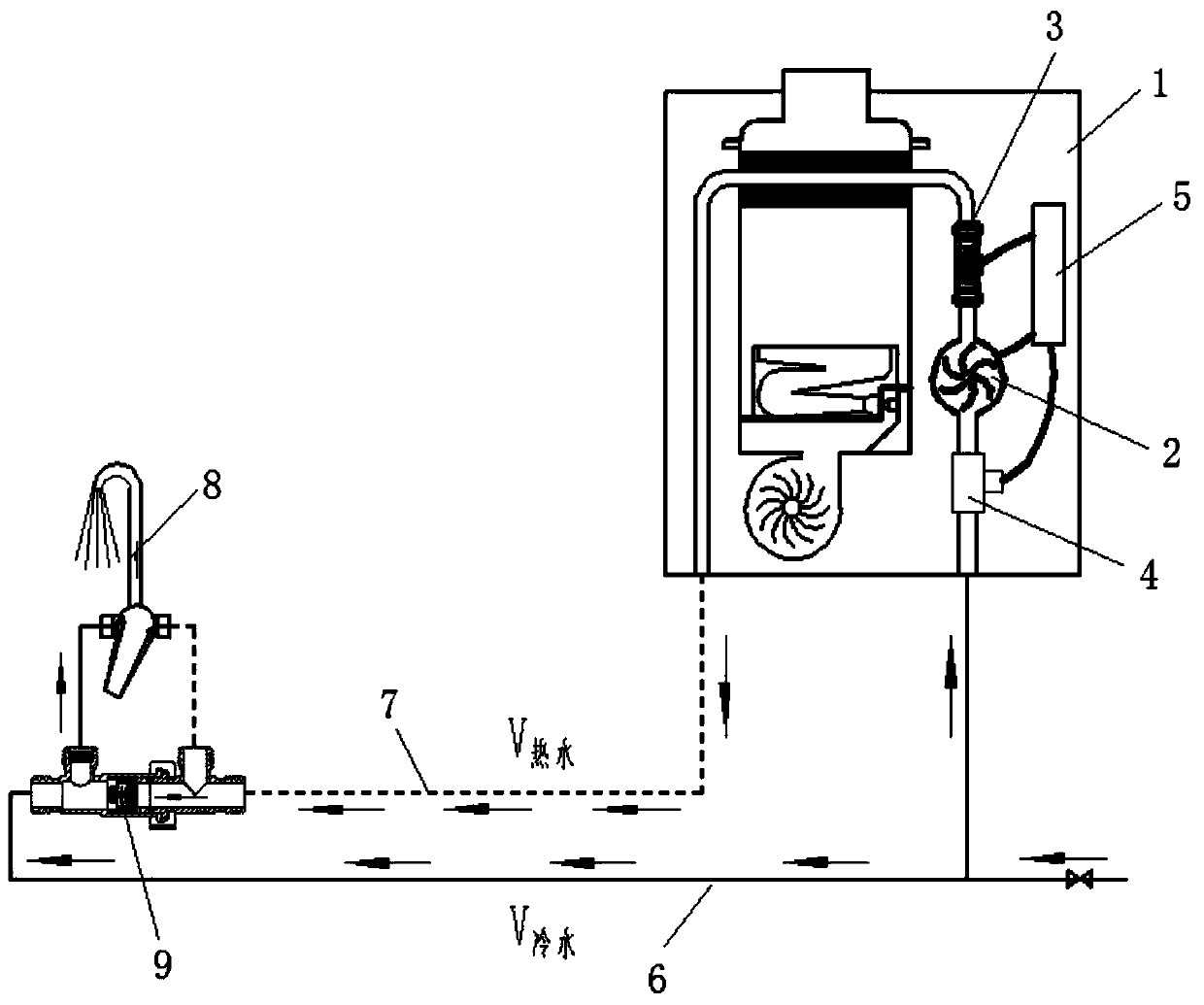

[0056] Embodiment 2 of the present invention provides a zero cold water gas water heater, such as image 3 As shown, it includes a gas water heater body 1, a circulation pump 2, a water flow acquisition unit 3, a water pressure acquisition unit 4, a controller 5, a cold water pipe 6, a hot water pipe 7, and a water terminal 8. The circulation pump 2, water The flow collection unit 3 and the water pressure collection unit 4 are both arranged on the main waterway in the gas water heater body 1 and are connected to the controller 5. One end of the cold water pipe 6 is connected to the water source, and the other end is connected to the water terminal 8. One end of the hot water pipe 7 is connected to the gas water heater body 1 , and the other end is connected to the water end 8 .

[0057] The water flow acquisition unit 3 includes a water flow sensor.

[0058] The water pressure acquisition unit 4 includes a water pressure sensor.

[0059] The other ends of the cold water pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com