LED lamp strip lamp mounting device convenient to disassemble

A technology for installing LED light strips and lamps, which is applied to lighting devices, components of lighting devices, and light source fixing. Easy disassembly, safe and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

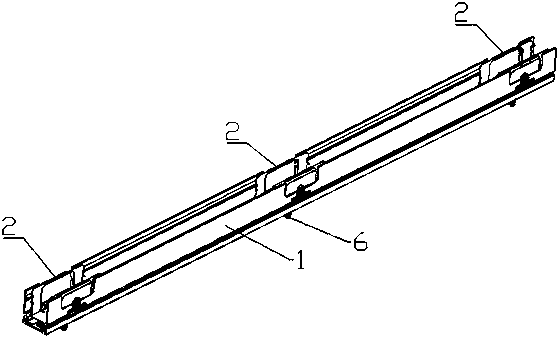

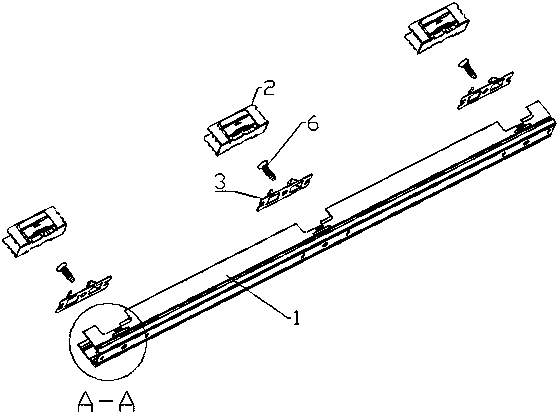

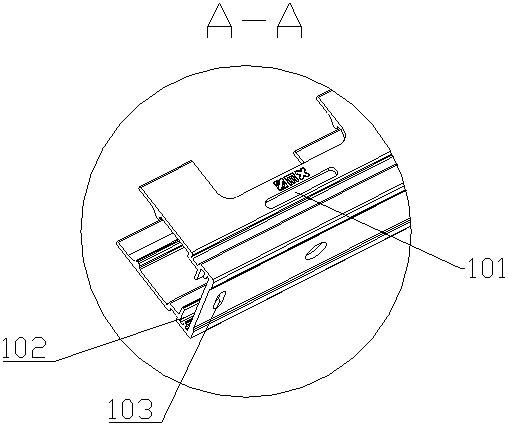

[0038] Such as figure 1 and Figure 5 as shown,

[0039] An easy-to-disassemble installation device for LED light strip lamps, including a fixing part 1, at least one light strip fastener 2, and an ejection mechanism 3, the ejection mechanism 3 is installed on the fixing part 1, and the side of the light strip fastener 2 is arranged There is a buckle 201 that plays a restrictive role. The fixing member 1 is provided with a buckle 101 that cooperates with the buckle 201 . push button switch 202;

[0040] When installing the light strip, the light strip fastener 2 is detachably fixed on the fixing part 1 through the buckle 201 and the clamp hole 101, and the light strip fastener 2 presses the pop-up mechanism 3 so that the pop-up mechanism 3 is in an energy storage state;

[0041] When removing the light strip, press the button switch 202 on the light strip fastener 2 to release the cooperation between the buckle 201 and the clamp hole 101 , and the pop-up mechanism 3 will ej...

Embodiment 2

[0055] Such as Figure 6 and Figure 11 as shown,

[0056] An easy-to-disassemble LED strip lamp installation device, including a fixing part 1, at least one strip fastener 2, an ejection mechanism 3, and a strip fastener base 4, and the strip fastener base 4 and the pop-up mechanism 3 are simultaneously fixed On the fixing part 1, the pop-up mechanism 3 is located between the base 4 of the light strip fastener and the fixing part 1, and the bottom of the light strip fastener base 4 is provided with a through hole for the shrapnel 302 of the pop-up mechanism 3 to pass through. 401, the side of the light strip fastener 2 is provided with a buckle 201 that acts as a restriction, the base 4 of the light strip fastener is provided with a card hole 101 that cooperates with the buckle 201, and the light strip fastener 2 There is also a button switch 202 for releasing the cooperation between the buckle 201 and the card hole 101;

[0057] When installing the light strip, the light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com