Material overheating aging and gas pyrolysis detection test device

A technology of pyrolysis and test equipment, which is applied in measuring equipment, analysis materials, weather resistance/light resistance/corrosion resistance, etc., and can solve problems such as neglecting physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

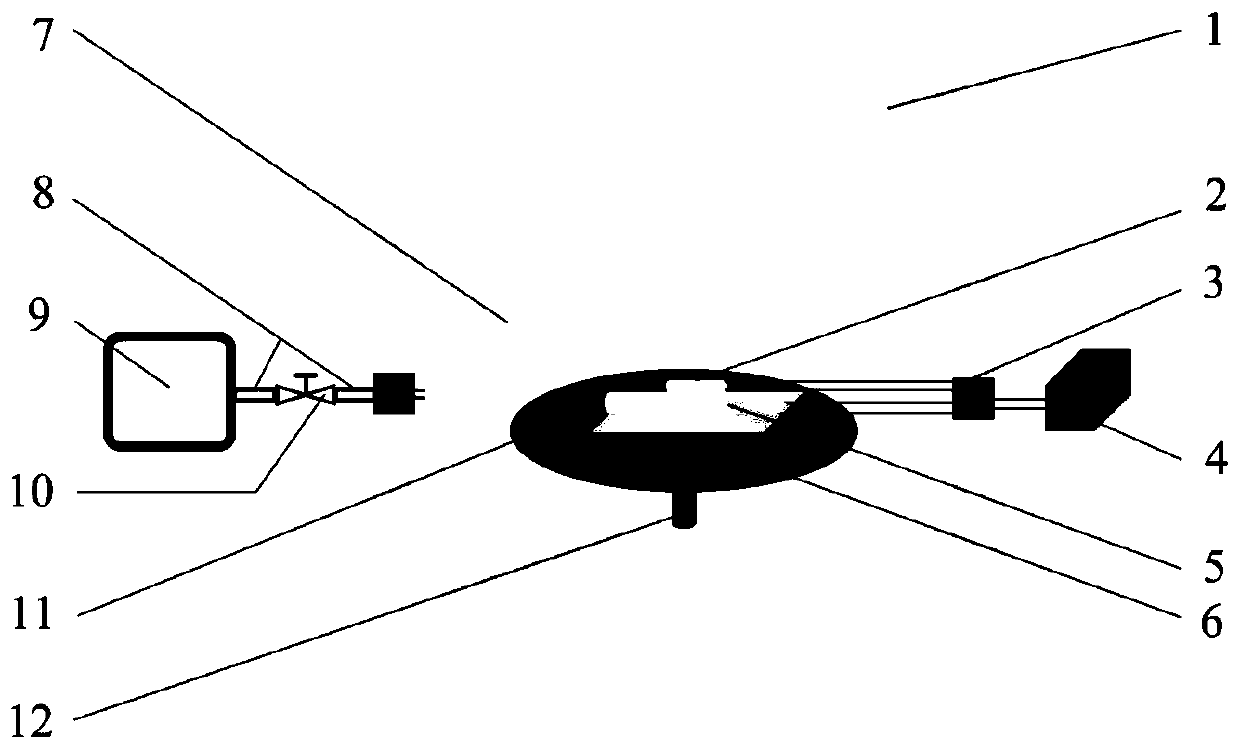

[0019] Such as figure 1 The specific structure of a field-applied maintenance isolation plate shown is as follows:

[0020] The whole device is divided into a solid material overheating aging part, a gas overheating pyrolysis detection part and a sample placement part.

[0021] The sample placement part puts solid insulating material and gas inside the stainless steel test chamber 1 , and the insulating material sample is placed on a red copper tray 11 fixed by stainless steel pillars 12 .

[0022] The solid material overheating and aging part is composed of a temperature sensor 2, an aviation plug 3, a temperature controller 4 and a heating tube 5. An aviation plug 3 is installed on the side wall of the test cavity 1, and the aviation plug 3 is placed inside the test cavity 1, and a temperature sensor 2 and a heating pipe 5 are installed on the inside, and a temperature controller 4 is installed on the outside. The temperature controller 4 adopts PID to adjust and control t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com