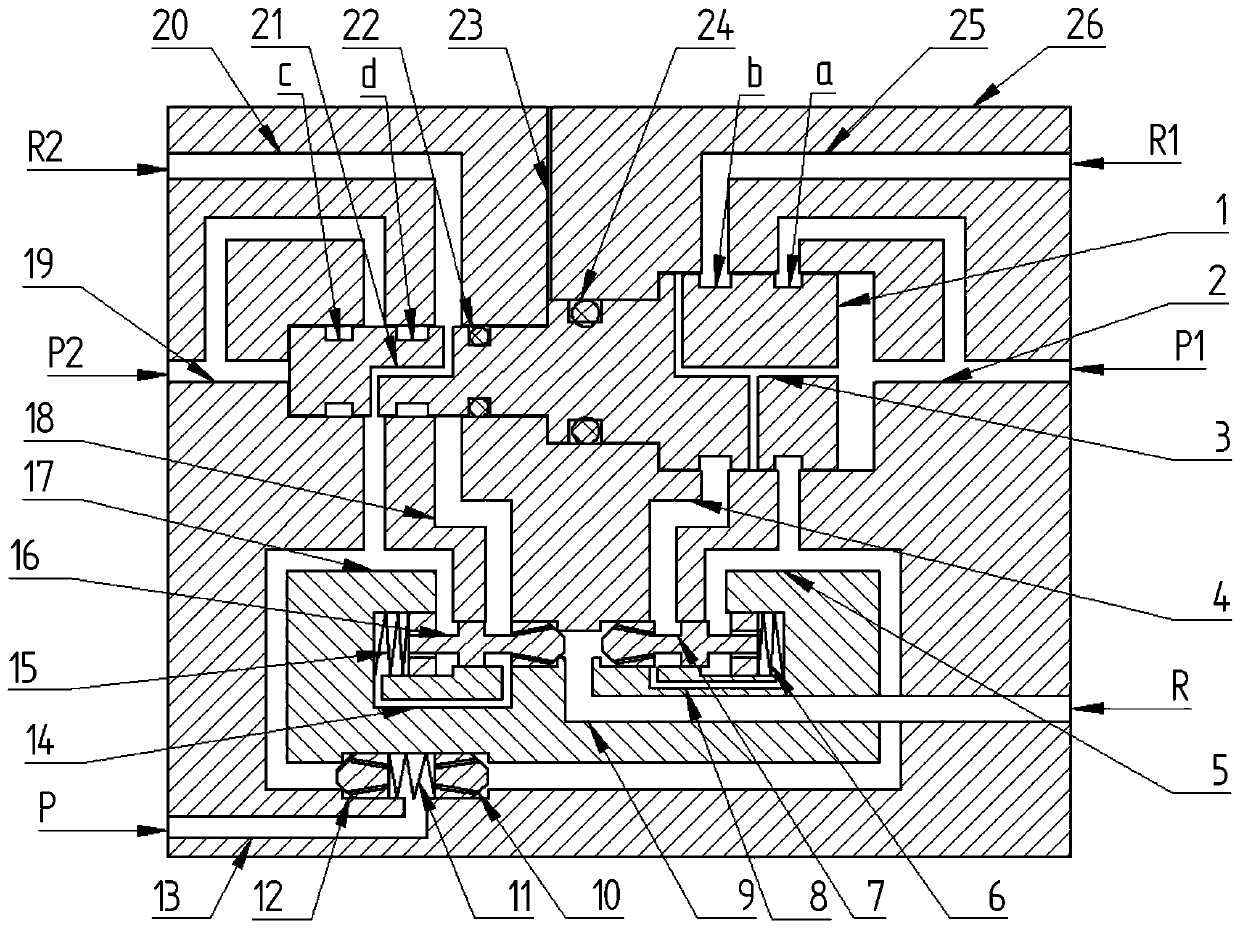

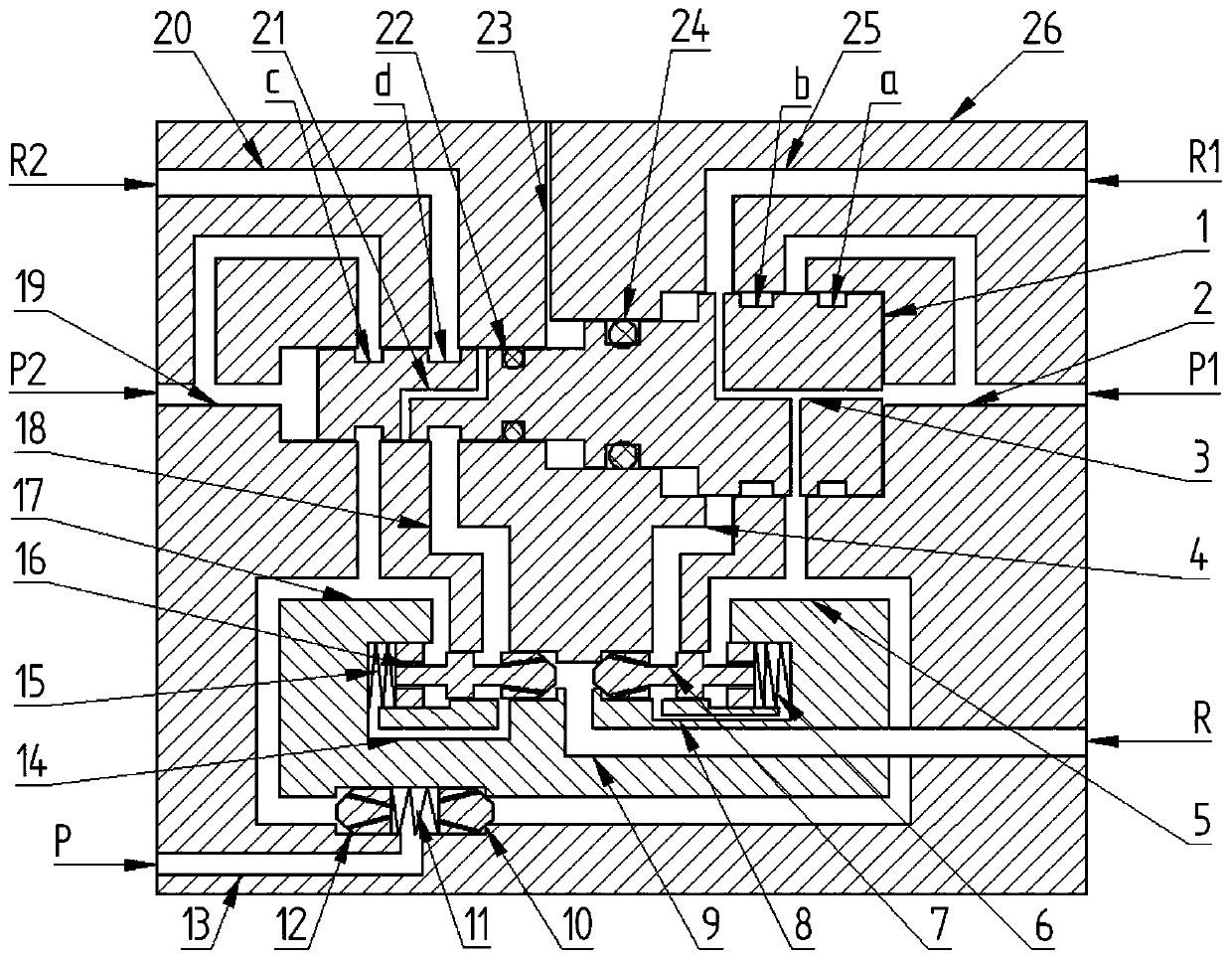

Zero oil swap energy conversion valve with double hydraulic systems

A technology of energy conversion and zero leakage of oil, which is applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problems of danger, difficulty in inspection, etc., and achieve reliable oil supply, solve leakage, and flexible conversion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] refer to Figure 1 ~ Figure 2. In the preferred embodiment described below, a dual-hydraulic system zero-sequence oil energy conversion valve includes: a valve body 26 of a dual-hydraulic system that communicates with the normal pressure oil circuit and the emergency pressure oil circuit, assembled on the valve body 26 The shaft shoulders with different heights are restricted in the cavity, and the step slide valve 1 moves along the axis direction or the movement trend, and each section of the step slide valve 1 is respectively formed with annular grooves a, b, c, d and sealing ring groove, it is characterized in that: the unloading hole 23 connected to the stepped hole of the valve cavity is formed on the valve body 26, and the upper body of the valve cavity of the head and tail stepped holes is symmetrical to each other, and the radial direction corresponds to the annular groove a, b, c , d are bent upwards in parallel, respectively connected to the second oil inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com