A Creep Correction Method for Load Cell

A load cell and creep technology, applied in the field of electronic scales, can solve the problems of high manufacturing process requirements, inaccurate correction, and high manufacturing cost of load cells, meet the needs of high-precision measurement, improve applicability, and avoid deviations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

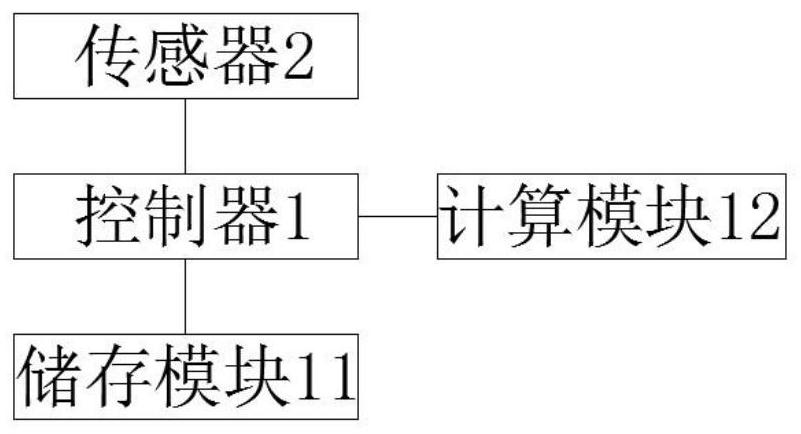

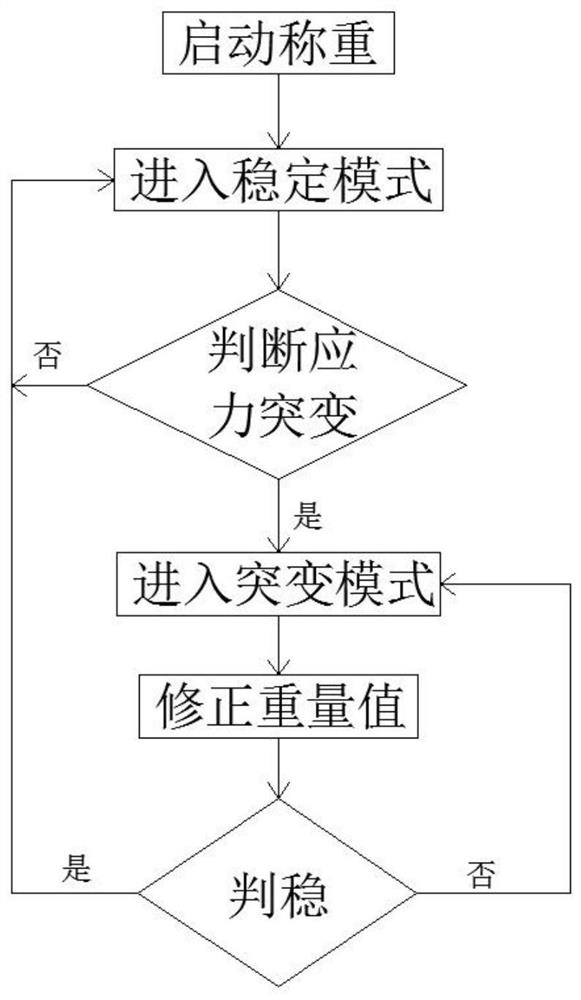

Method used

Image

Examples

Embodiment 1

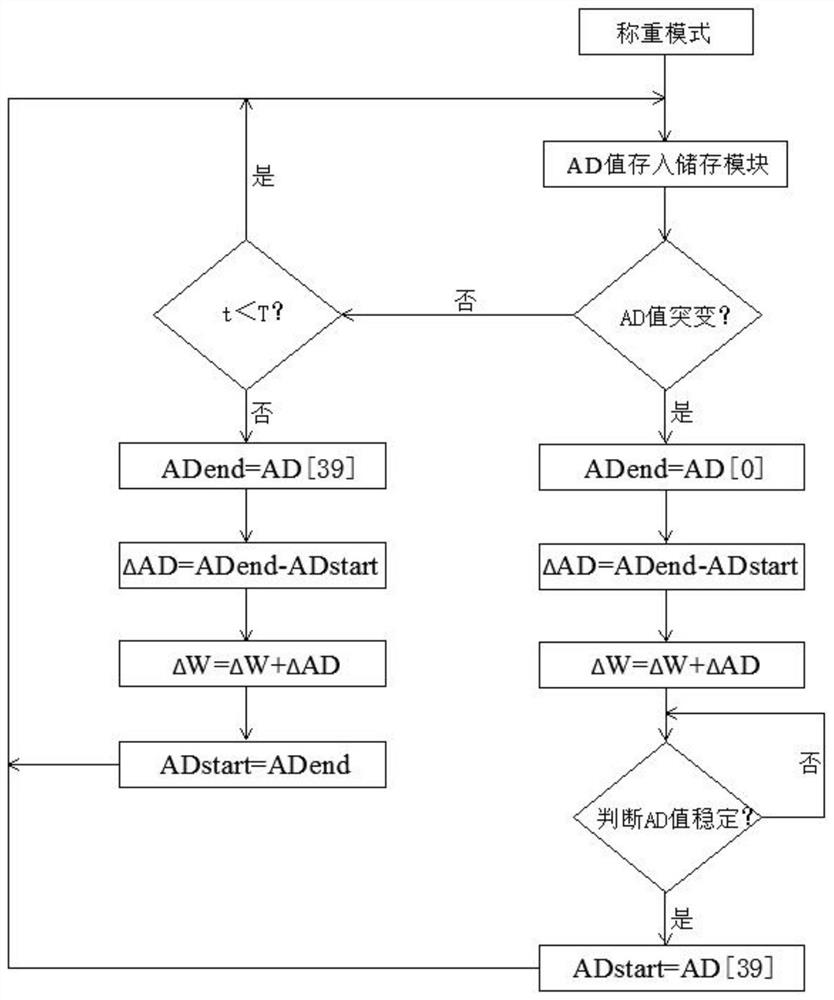

[0050] In this embodiment, the electronic scale adopts the following parameters to set T=500ms, a=40, X=10, m=100.

[0051] Then in the stable mode, the controller 1 will detect the AD value 40 times at intervals of 500ms, and the sensor 2 can be recorded as AD[0], AD[1]...AD[39] according to the recording sequence.

[0052] When the controller 1 judges stable, the controller 1 sets the sensor 2 at T trig The bth AD value measured in the time period is recorded as T trig AD[b], first determine whether the b-1th AD value measured by sensor 2 is stable compared with the bth AD value, AD temp =T trig AD[b]-T trig AD[b-1], if AD is judged temp ≥10, it is judged that the AD value is unstable at this time, and the number of judgments Y is recorded as 0, that is, Y=0; if it is judged that AD temp <10, it is determined that the AD value is stable at this time, and the number of times Y is added to Y=Y+1. When the number of times Y≥100, it is determined that the AD value has stabi...

Embodiment 2

[0055] In this embodiment, the electronic scale does not use any creep correction method, and in an environment with a temperature of 25°C and a humidity of 60%, several measurements are made on a 165g object. The measurement results are as follows: Figure 5 Shown in curve b.

[0056] It can be seen from the figure that curve b will change with time, and will gradually move up when weighing the same item. Compared with curve a and curve b, curve a is processed by creep correction method, and the weight value is stable. There will be no problem that the weight value rises with time, and the measurement error caused by the creep of the load cell 2 itself is well solved to ensure the measurement accuracy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com