Efficient maintenance device for glazed tile production

A glazed tile, high-efficiency technology, applied in the direction of ceramic molding machines, manufacturing tools, auxiliary molding equipment, etc., can solve the problems of poor maintenance quality of glazed tiles, accelerate the breakage of glazed tiles, etc., and achieve the effect of improving maintenance efficiency, simple structure, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

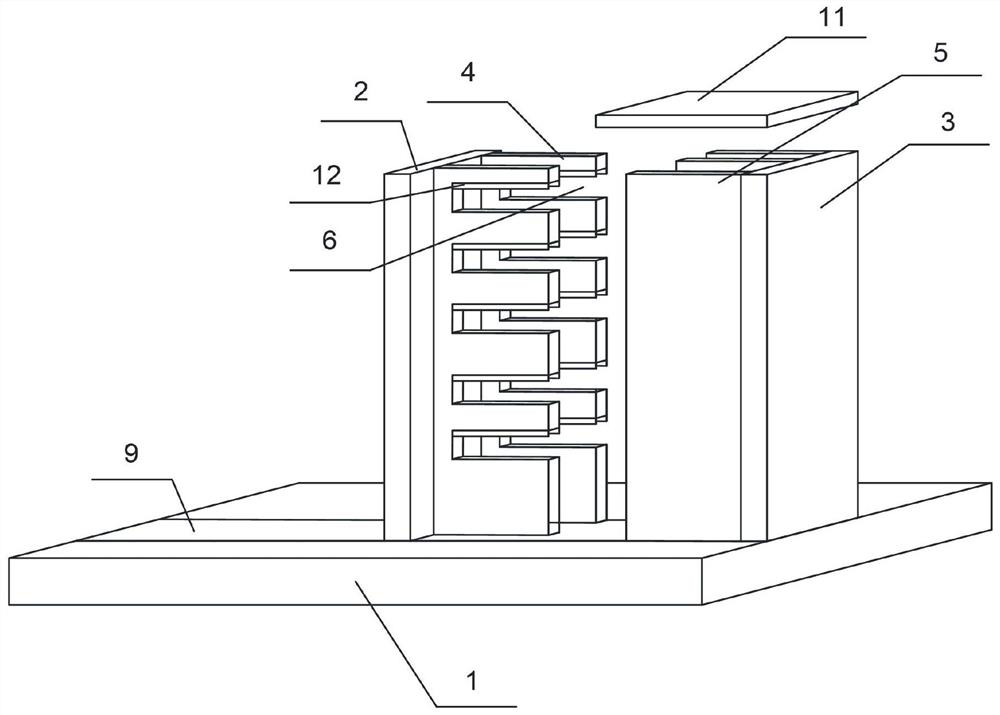

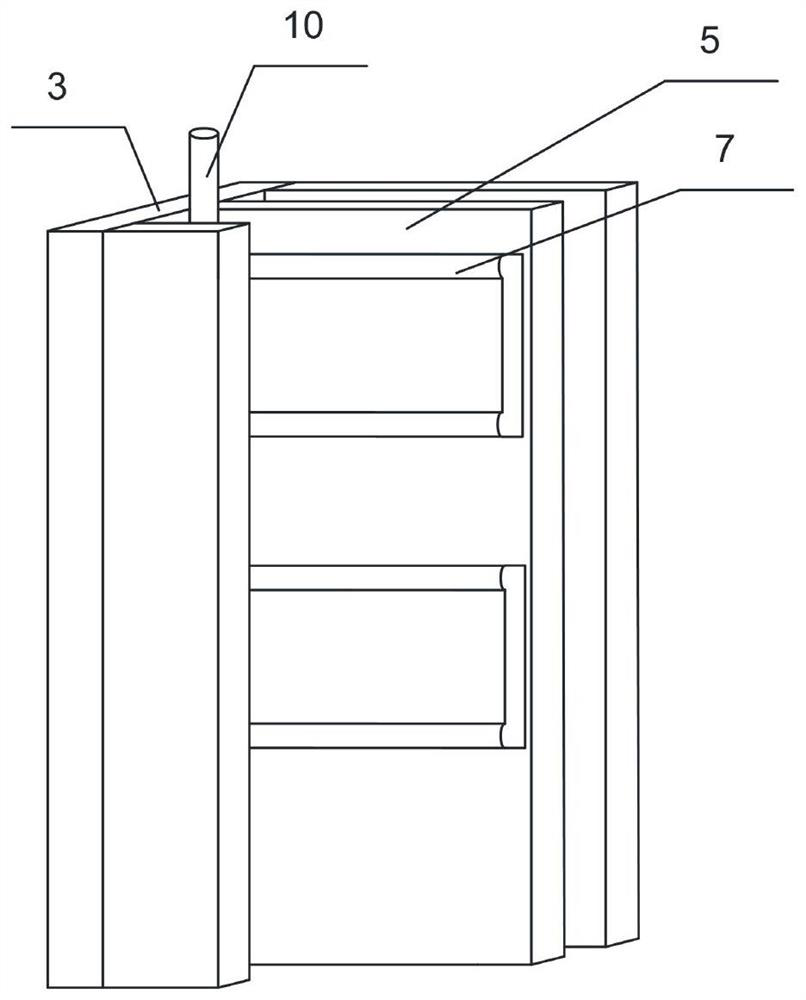

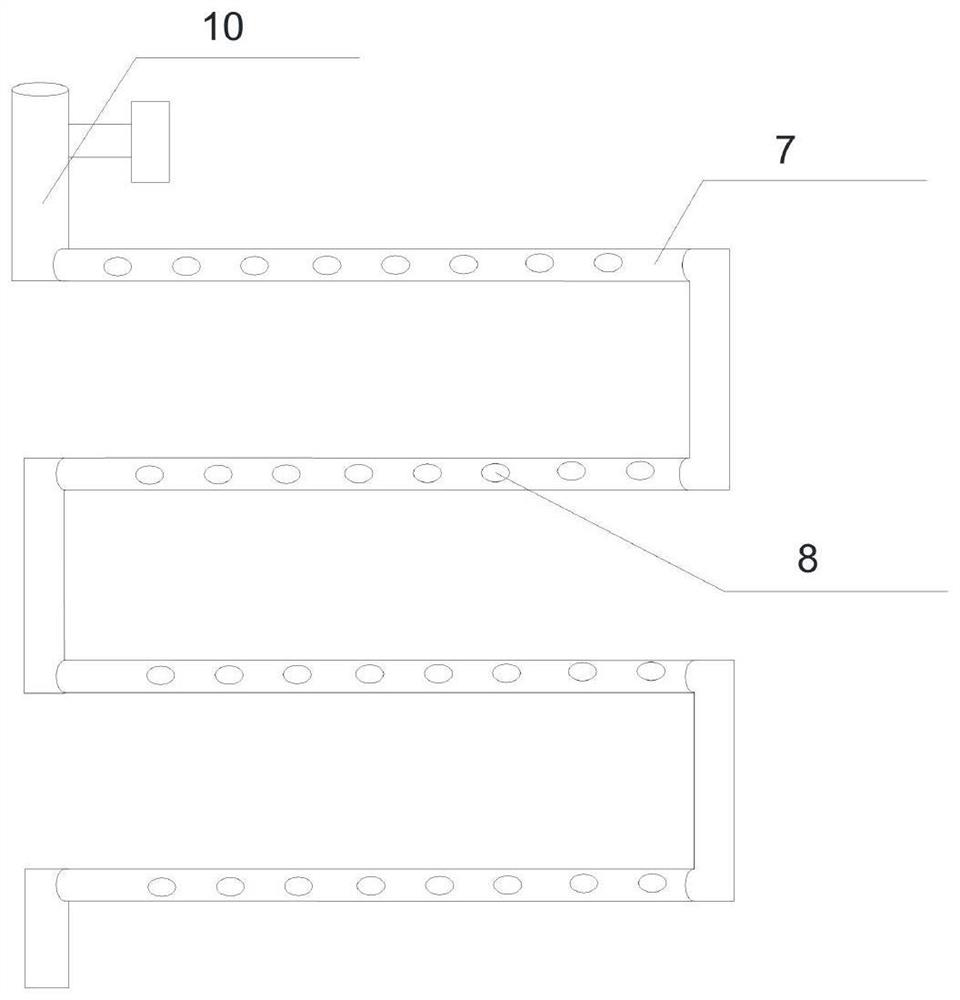

[0025] Such as figure 1 , figure 2 , image 3As shown, the high-efficiency maintenance device for glazed tile production of the present invention includes a horizontally placed cuboid base 1, a vertically placed slide plate 2 and a fixed plate 3 are arranged above the base 1, and the slide plate 2 and the fixed plate 3 are equal in size and parallel to each other. The skateboard 2 and the fixed board 3 are arranged in sequence along the long side of the base 1. The centerlines of the skateboard 2 and the fixed board 3 in the long side direction of the base 1 coincide with each other. The boards 4 arranged in parallel, each board 4 is placed vertically and perpendicular to the slide plate 2 and the base 1, all the boards 4 are arranged one by one along the width direction of the base 1, and the side of the fixed board 3 facing the slide board 2 is connected with A plurality of dividers 5 equidistantly arranged in parallel, each divider 5 is placed vertically and is perpendic...

Embodiment 2

[0028] Based on Embodiment 1, a pressurized pipe 10 is communicated above the uppermost water pipe 7, the water outlet of the pressurized pipe 10 is communicated with the water inlet of the uppermost water pipe 7, and the water inlet of the pressurized pipe 10 is communicated with a pump. The water pumped into the pressurizing pipe 10 flows through all the water pipes 7 sequentially from top to bottom and flows out from the water outlet of the lowermost water pipe 7 . The pump can pressurize the water entering the water pipe, increase the flow speed, spray volume and spray distance of the water flow, ensure that all the glazed tiles are soaked in water, and improve the maintenance efficiency of the entire room; the water flowing out of the bottom pipe is recycled , can realize the reuse of water.

Embodiment 3

[0030] Based on the above-mentioned embodiment, a cover plate 11 is arranged above the fixed plate 3, and the cover plate 11 is a rectangular plate placed horizontally. On the top surface, the broadside of the cover plate 11 is parallel to the broadside of the base 1, the length of the broadside of the cover plate 11 is greater than the length of the fixed plate 3 in the direction of the wide side of the base 1, and the distance between the cover plate 11 and the fixed plate 3 and the slide plate 2 The top surface is secured by bolt connections.

[0031] The cover plate seals the top surface of the rectangular frame formed by the sliding plate, the fixing plate and the partition plate to strengthen the sealing of the rectangular frame. There are through holes on the cover plate to facilitate the installation of pipes to realize the water inlet of the water pipes. There are through holes on the base to facilitate Install the pipeline to realize the water outlet of the water pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com