Computer-implemented methods and systems for generating material processing robotic tool paths

A tool path and material handling technology, applied in general control systems, manufacturing tools, control/regulation systems, etc., to solve problems such as complex robot kinematics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

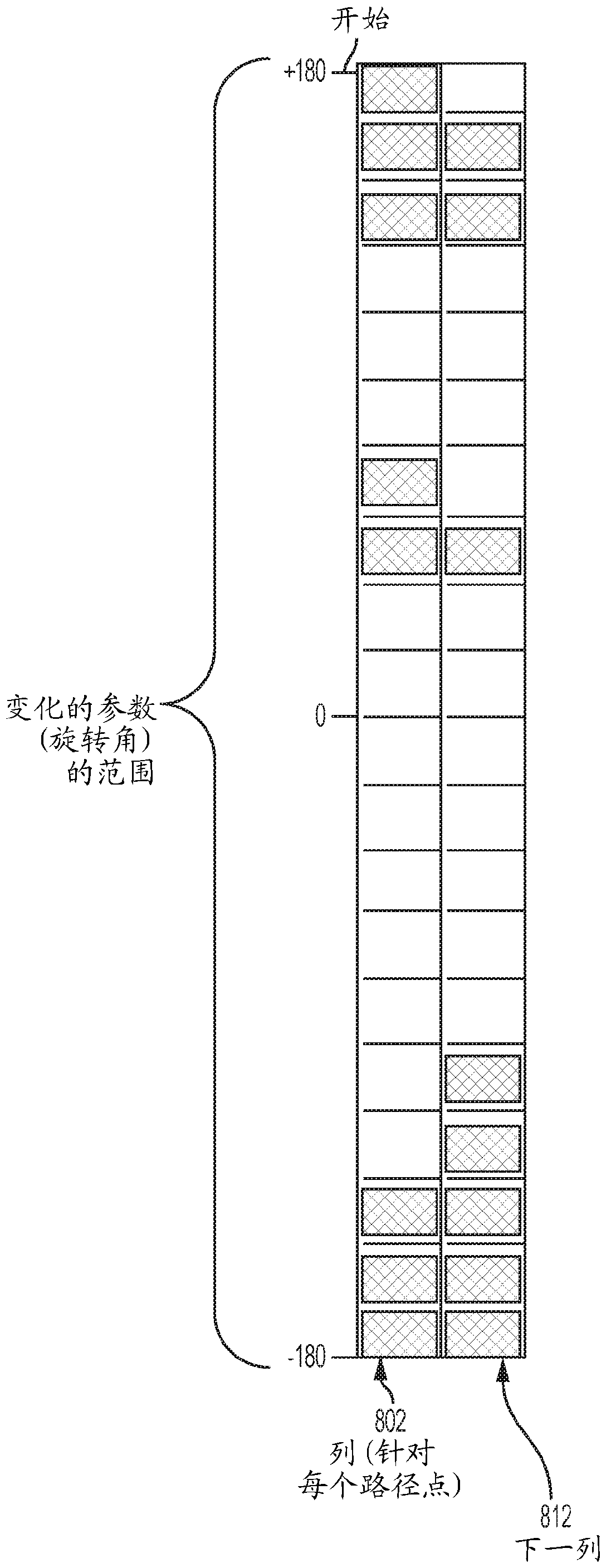

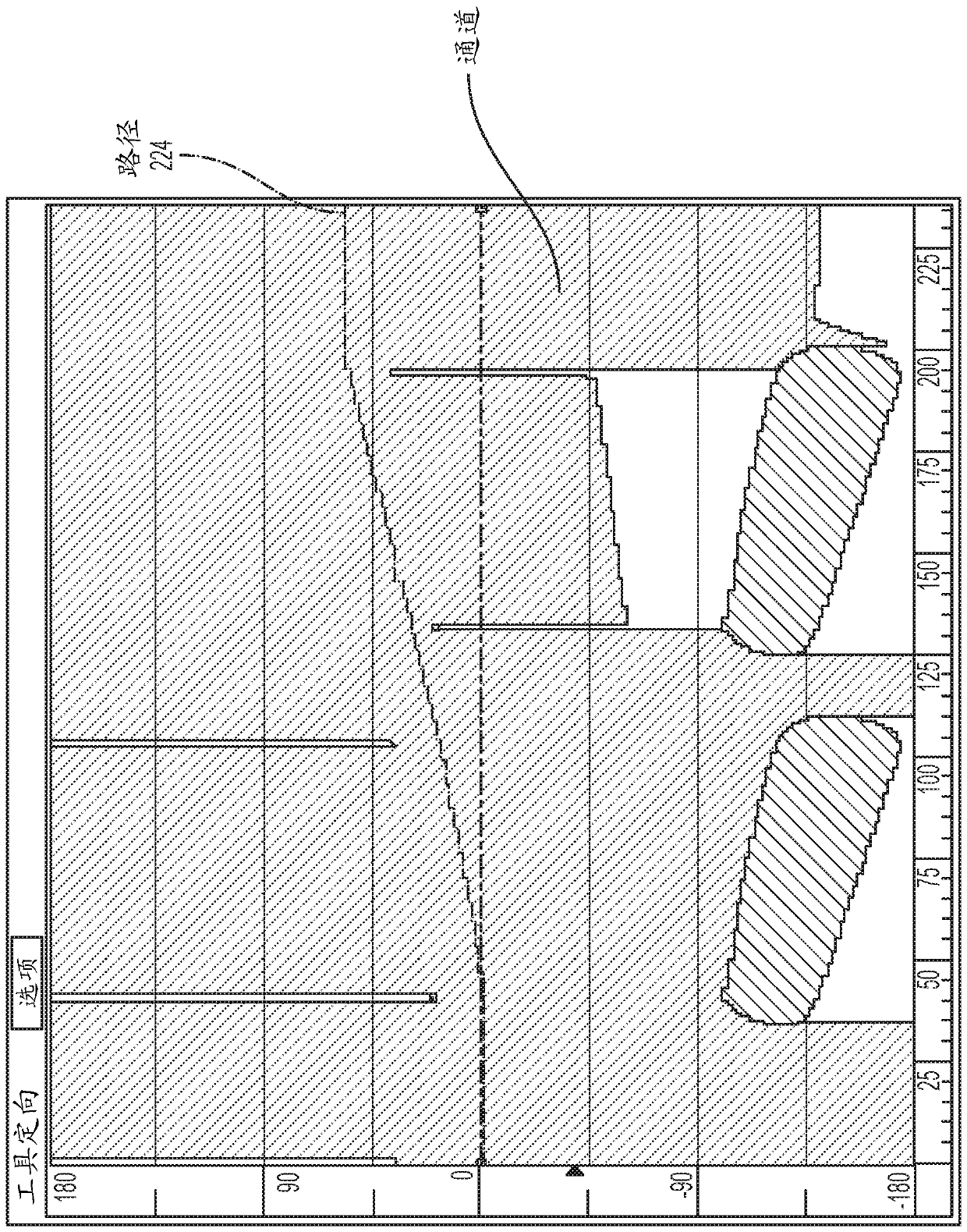

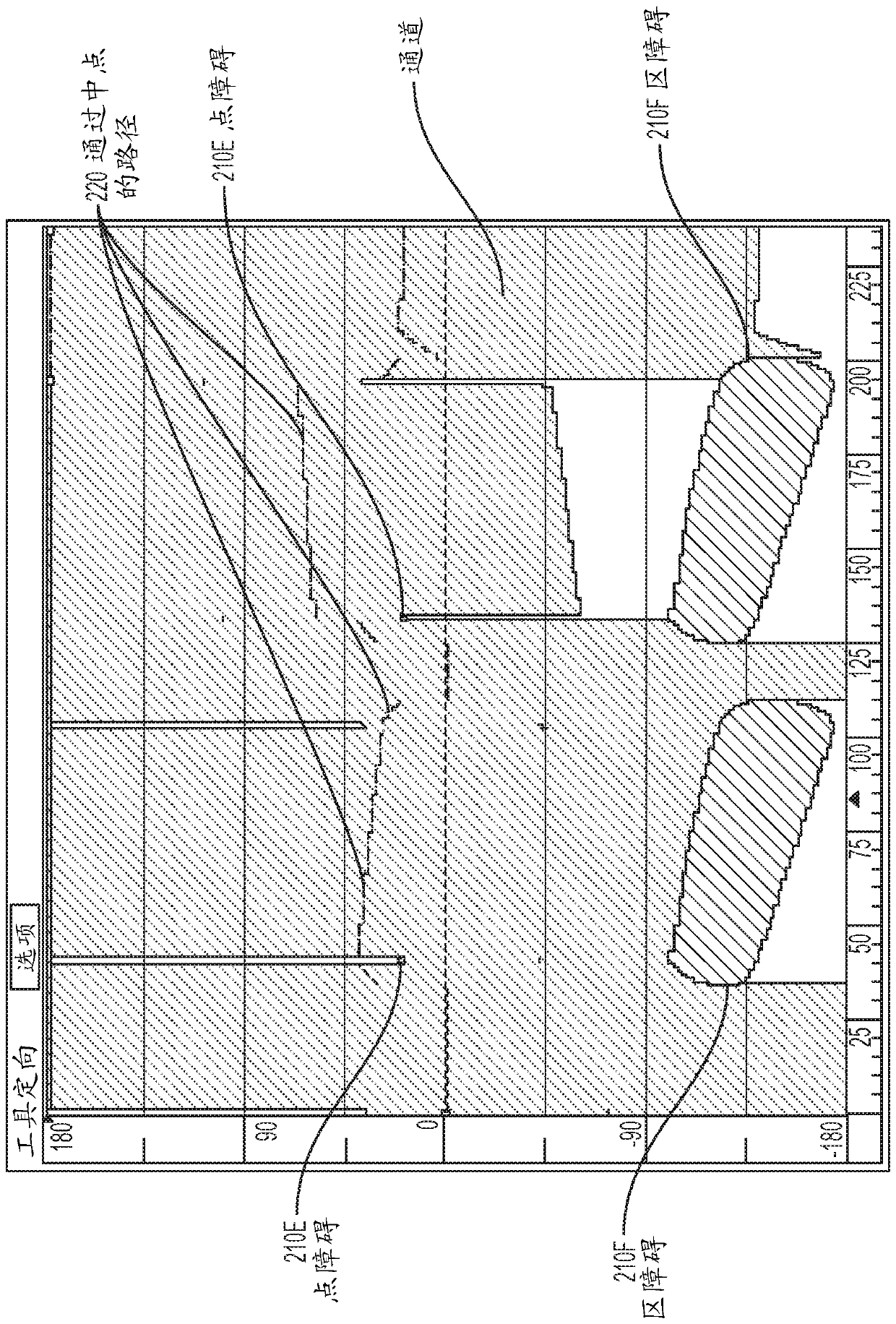

[0036] In some aspects, the systems and methods described herein can be used to more easily and efficiently plan material handling sequences to be performed by a tool coupled to and moved by a robotic tool handling system by utilizing One or more additional degrees of freedom available to the treatment system, such as manipulating the rotation of the tool about its longitudinal axis, and evaluating various potential robotic tool paths in an exhaustive manner to determine the most desirable tool path. In some cases, an exhaustive analysis can be performed by comparing the potentially desired robotic system configuration that will be able to deliver the tool in its intended location with the actual physical parameters of the robotic tool handling system, and based on known The physical parameters of the robot analyze whether the robotic tool handling system can indeed deliver the tool to the intended location, or whether one or more obstacles will limit the ability of the robotic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com