Compound broadband muffler with multi-layer structure

A multi-layer structure, muffler technology, applied in the direction of intake muffler, machine/engine, engine components, etc., can solve the problems of complicated filter processing technology and high price, and achieve the effect of avoiding use, eliminating noise, and improving noise reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

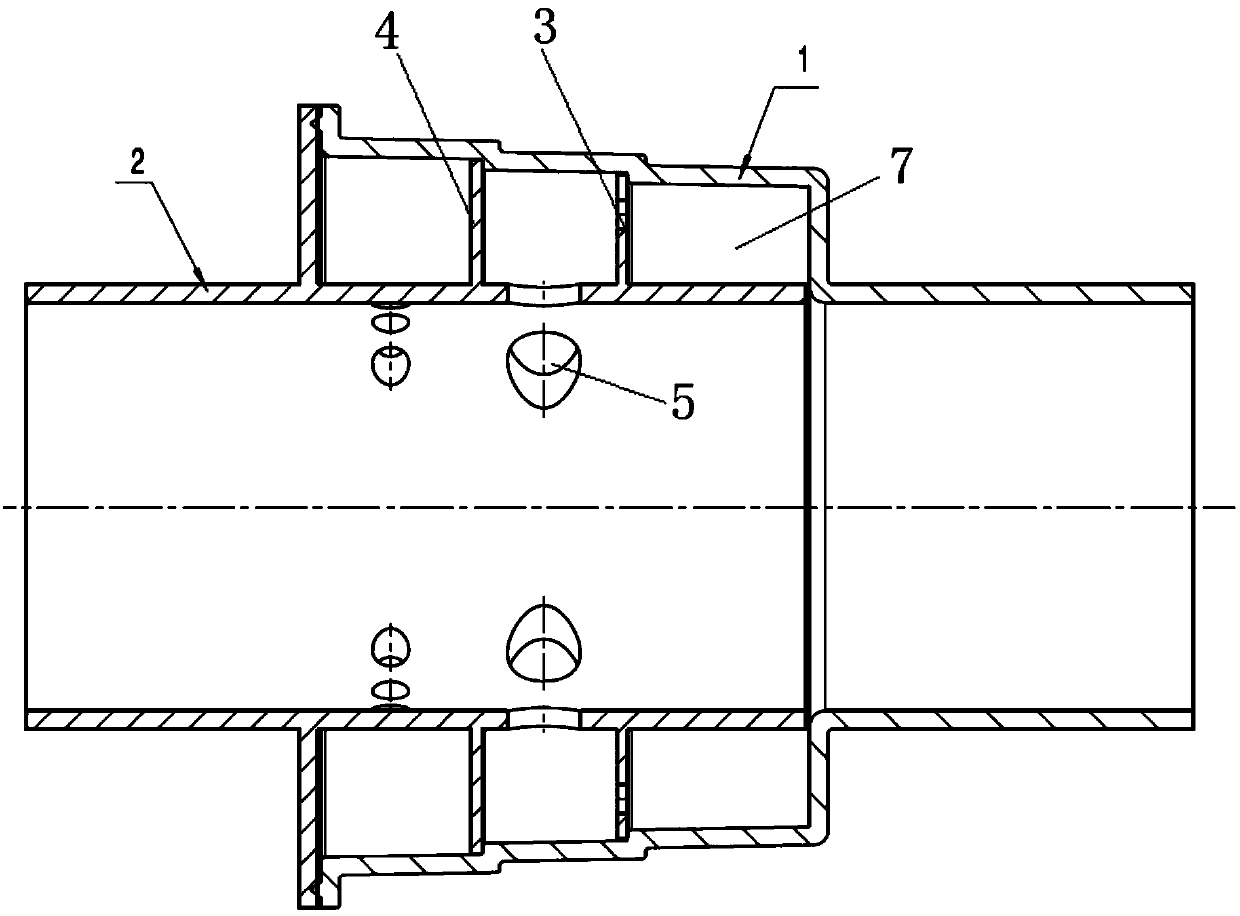

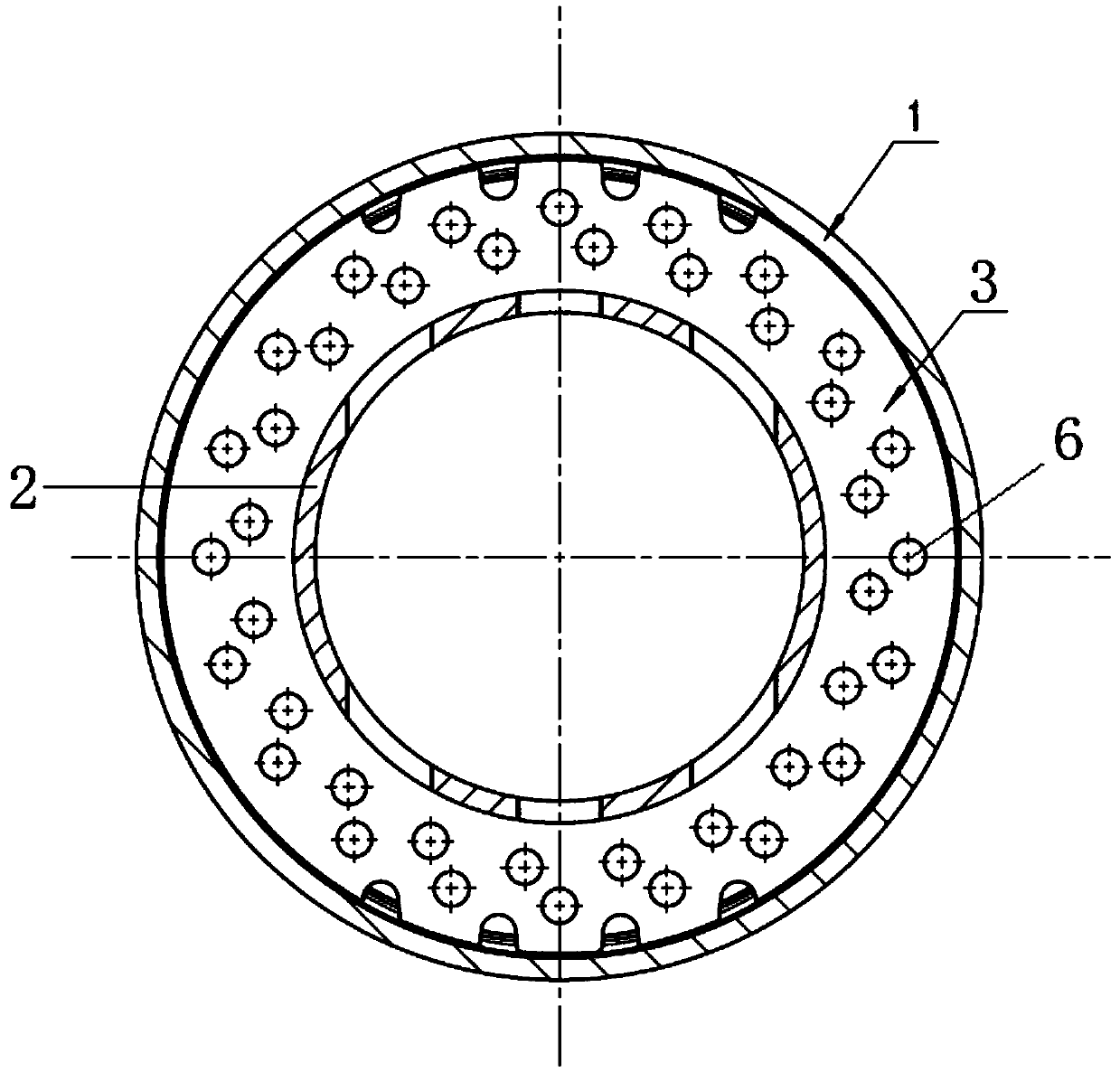

[0024] A composite broadband muffler with a multi-layer structure, such as figure 1 As shown, it includes a shell 1 and a central tube 2 coaxially arranged in the shell. A closed sound-absorbing chamber is formed between the central pipe 2 and the shell 1. Two partitions 3 and 4 are arranged in the sound-absorbing chamber, and the central pipe 2 is provided with The sound-absorbing hole 5 that communicates with independent space. In this embodiment, the shell 1 is a stepped cylindrical structure, and the partitions are arranged at the subsections of the stepped cylindrical shell 1. The ratio of the diameter of the shell 1 to the diameter of the central tube is about 1.5:1, and the partition is a circle. The ring is vertically arranged on the central tube, and the central tube and the shell are welded together. The partitions 3 and 4 divide the sound-absorbing cavity into three independent spaces 7 . Wherein, the leftmost independent space 7 communicates with the central pipe...

Embodiment 2

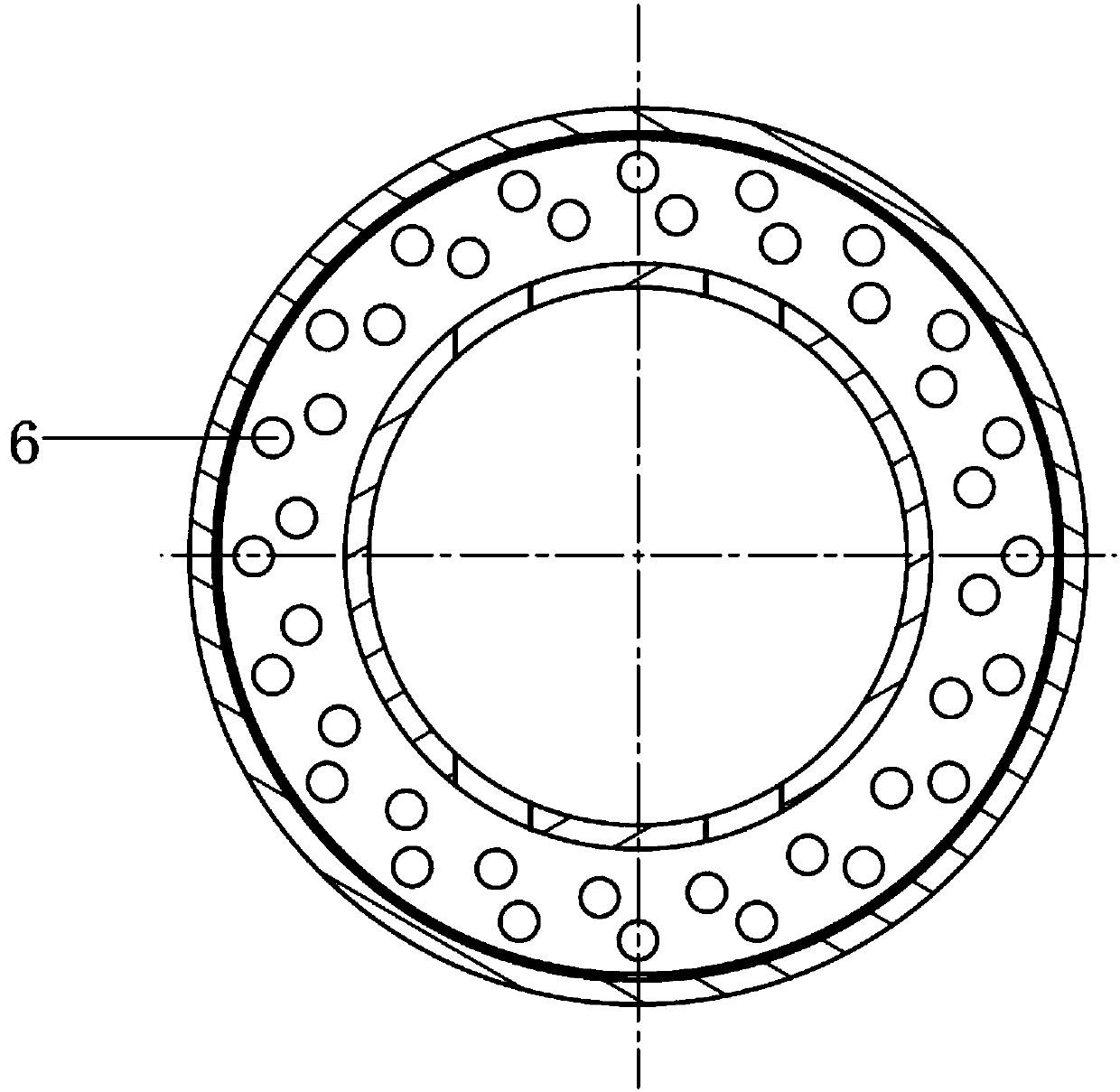

[0027] The difference from Example 1 is that only one partition 3 is provided in this embodiment. The partition 3 divides the airtight silencer cavity formed between the central tube 2 and the shell 1 into two independent spaces. The left independent space and the central tube 2 pass through the silencer. The hole 5 is connected, and the air hole 6 is provided on the partition 3, so that the independent space 7 on the right is connected with the one on the left.

Embodiment 3

[0029] Different from Embodiment 1, this embodiment only has three partitions. The partitions divide the airtight silencer cavity formed between the central tube 2 and the shell 1 into 4 independent spaces. From left to right, the first independent space And the third independent space is communicated with the center pipe 2 through the sound-absorbing hole 5, and the partition plate 3 between the second and fourth independent space and the adjacent independent space that is not communicated with the center pipe 2 through the sound-absorbing hole 5 is provided with a through-hole There are 6 air holes, and the other partitions do not have holes, so that a multi-layer composite porous resonant cavity can be formed. By using the impedance of the multi-layer resonant structure to cause the reflection of sound waves to eliminate noise, it has a better noise reduction effect and can eliminate wider frequency noise.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap