Effectiveness Monitoring Method for Rejection of Online Quality Inspection System of Cigarette Packing Machine

A technology for packaging machines and cigarette packs, which is applied to packaging cigarettes, cigars, etc., can solve the problems of scattered layout, flow of cigarette packs into the next process, and distortion of the detection results of the re-inspection function, so as to ensure the effect of ensuring no distortion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

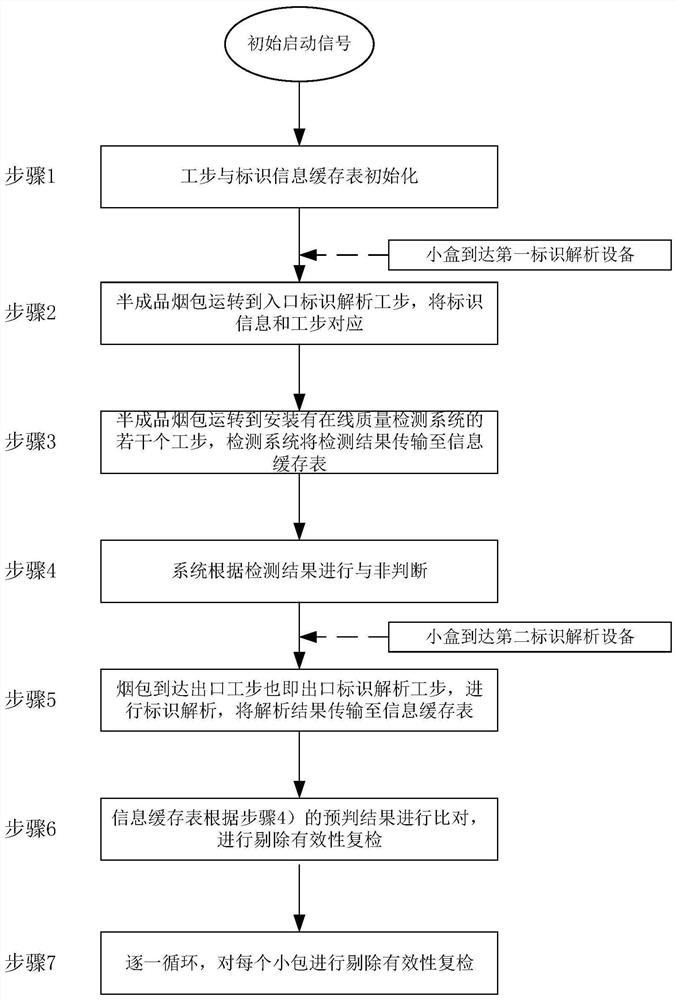

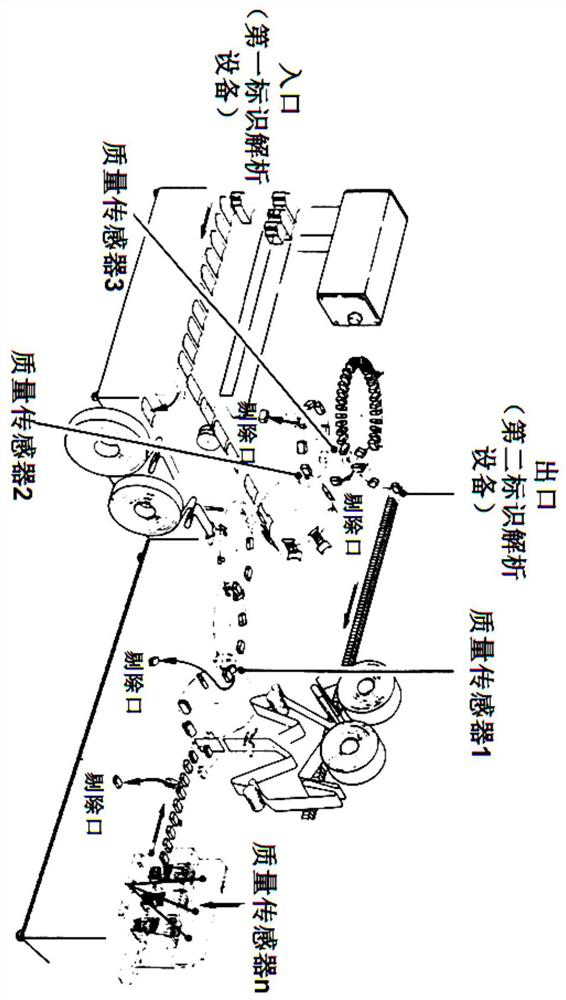

Method used

Image

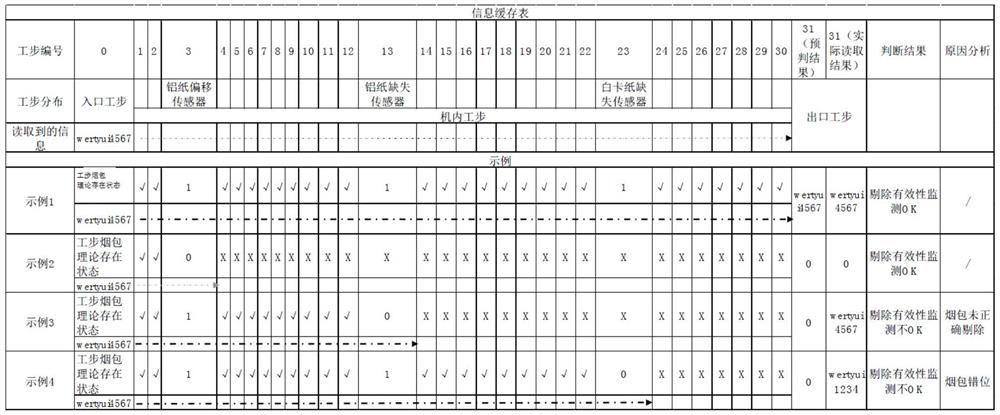

Examples

example 1

[0042]Example 1) When the three quality sensor detection results are qualified (three sensor detection results are 1), the cigarette pack should be present at the step 31, and if the information read by the second two-dimensional code is Wertyui4567, indicating that the review is passed;

example 2

[0043]Example 2) When the three quality sensor detection results have any one unqualified (such as 0), the cigarette pack should not exist at the step 31, if the second two days The information read by the code is empty, indicating that the cigarette pack has been properly removed, indicating that the recording is passed;

example 3

[0044]Example 3) Any one of the three mass sensor detection results (such as 0), if the aluminum paper deletion sensor detection result is 0), the cigarette pack should not exist in the step 31, if the information read is WERTYUI4567, Then, the retrieval is not passed, the cigarette pack is not removed correctly, and it needs to be alarm;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com