Dmd module

A technology of Peltier elements and cooling bodies, applied in the field of DMD modules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Concepts regarding location or orientation, such as for example "above", "below", "in front of", "below", "above" etc. have been chosen in this specification for simplicity only and may not It refers to the illustration in the drawing, but necessarily to the position of use or installation.

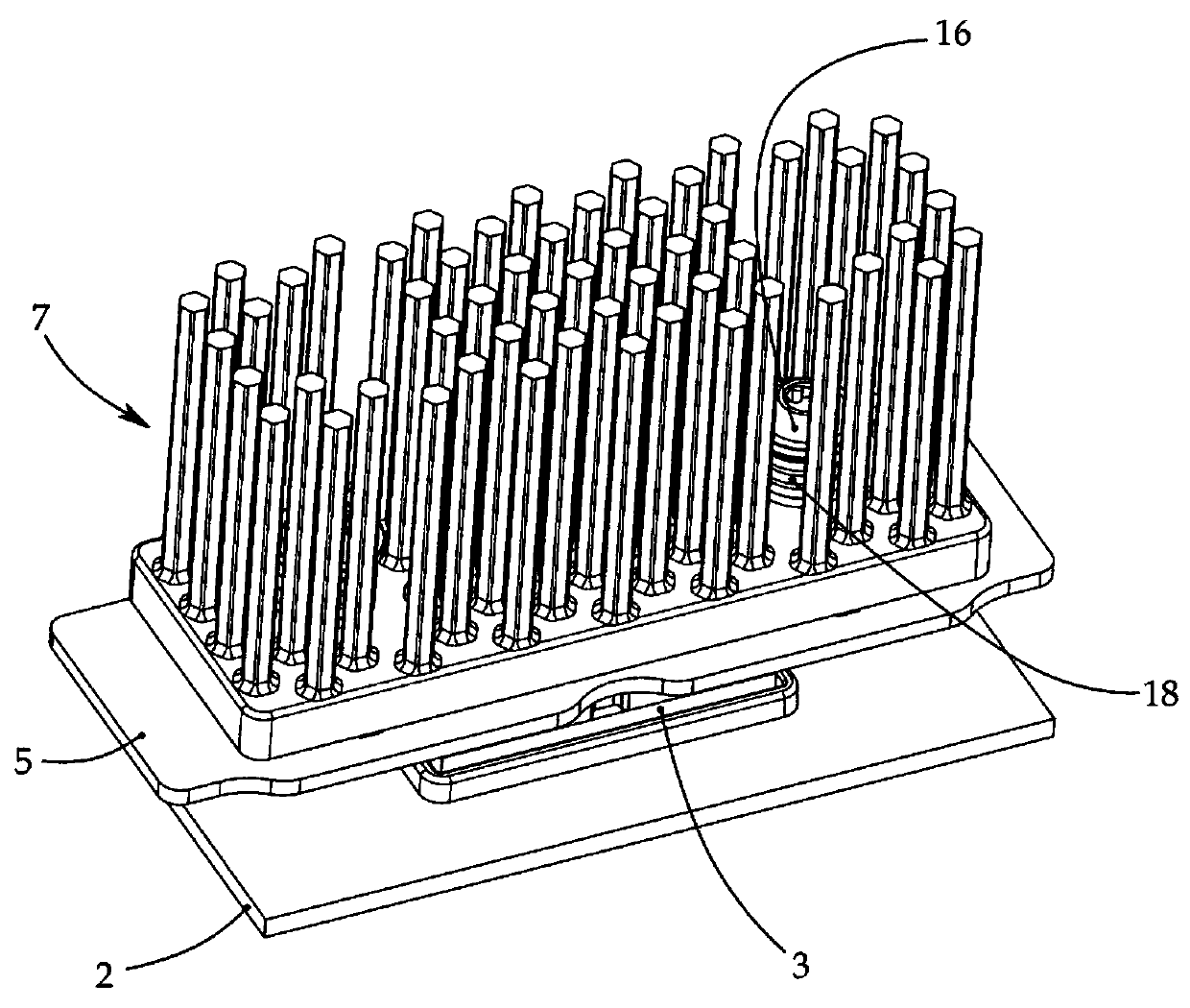

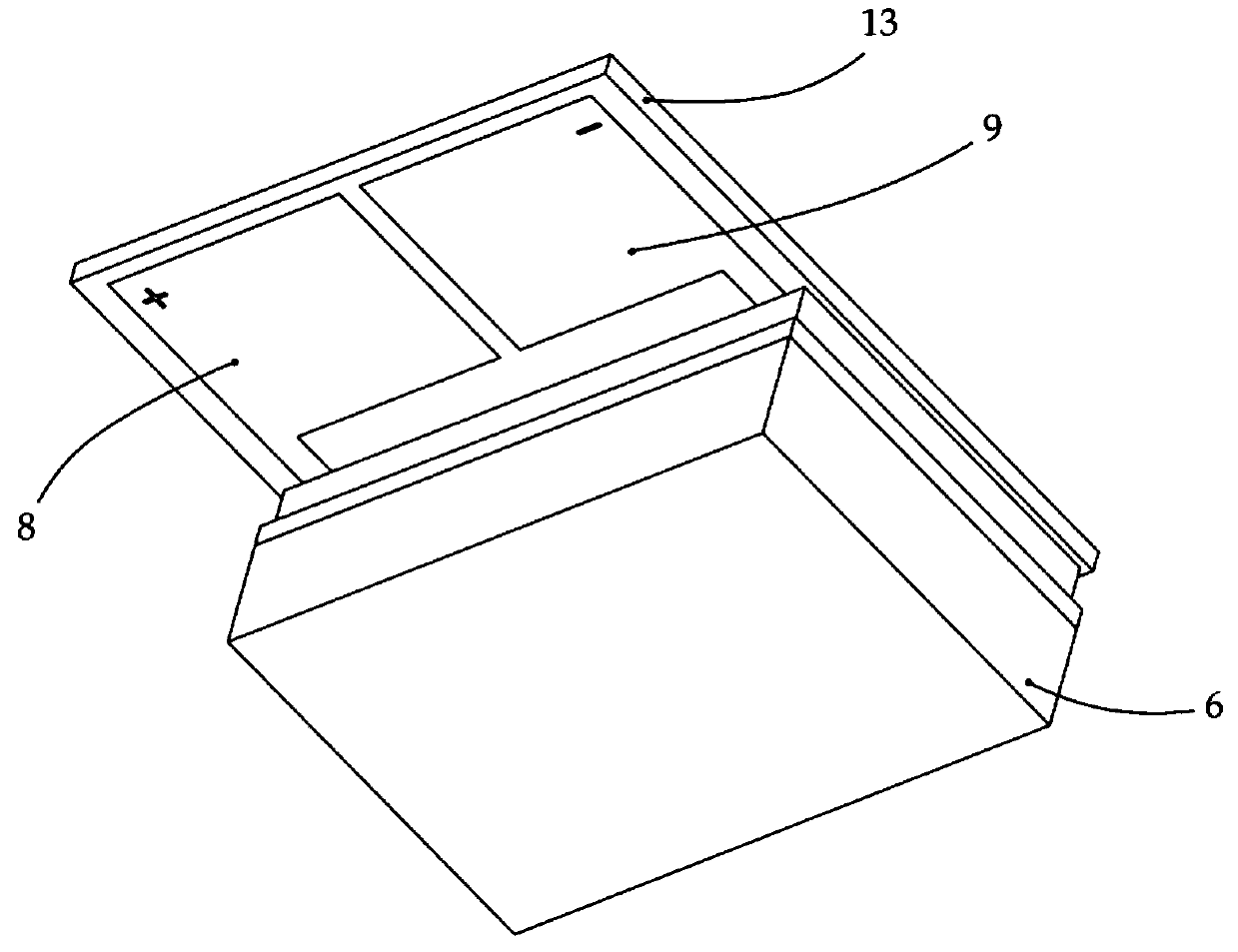

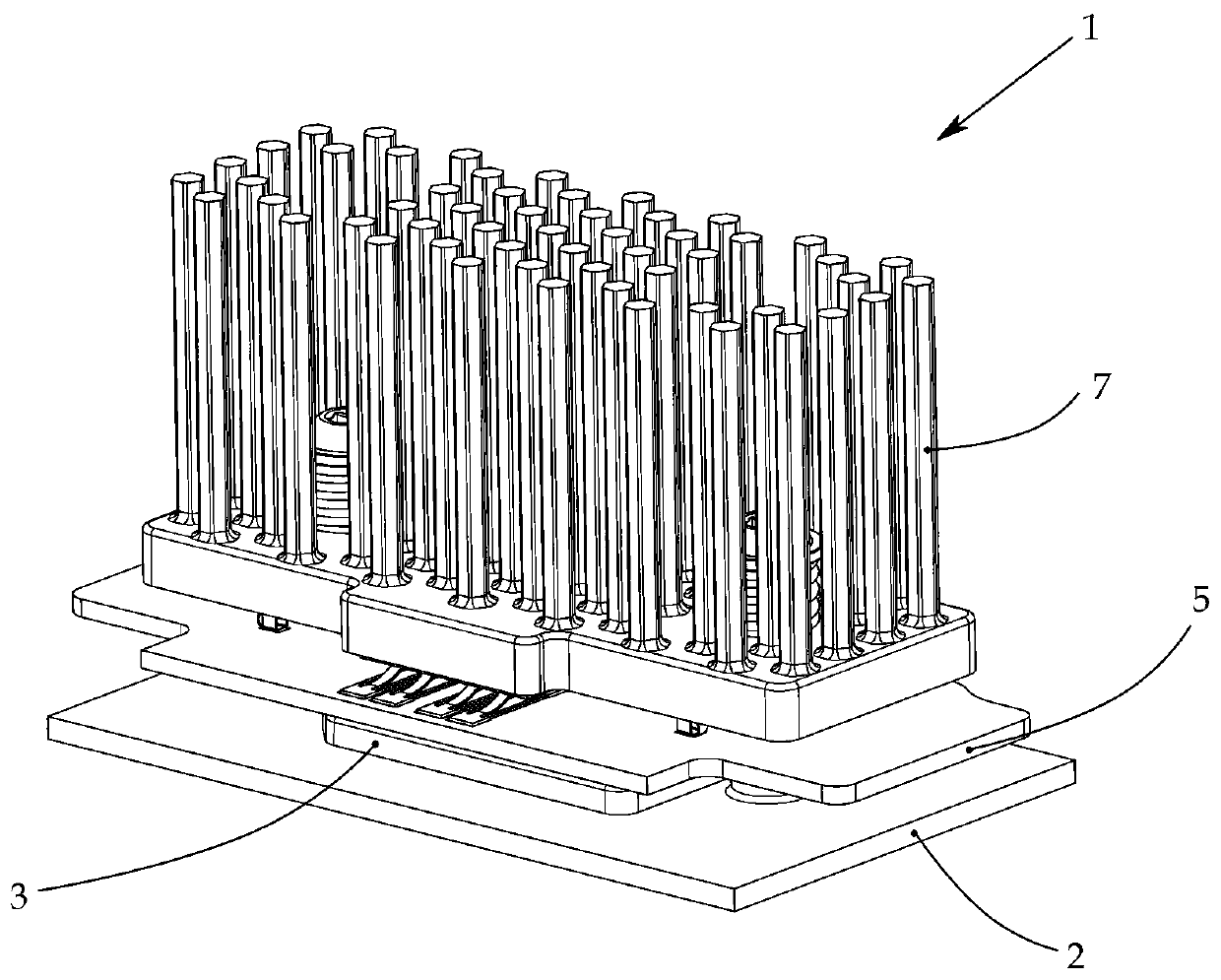

[0046] figure 1 , 2 , 3 and 8 each show a completed assembled DMD module, for which (wogegen, sometimes called opposite), Figures 4 to 7 should be used to illustrate the assembly of DMD modules and Figures 9 to 11 Involves the DMD element itself.

[0047] The figure shows a DMD module 1 according to the invention with a holding frame 2 into which a DMD element 3 is inserted. DMD element 3 has base 4, and described base is connected with conductor plate 5 by soldering, and wherein, actual DMD chip is plugged in base 4 by pin (Pins, is sometimes referred to as pin) and in base 4 is held by means of a spring clamp (Federklemmen, sometimes called a spring terminal). See especia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com