Polyester film electrostatic adsorption system

A technology of electrostatic adsorption and polyester film, applied in the direction of circuits, electrical components, corona discharge devices, etc., can solve the problems of electrostatic adsorption parameters not adjusted properly, high-voltage discharge, broken electrode wire, etc., to solve the problem of unreliable conduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

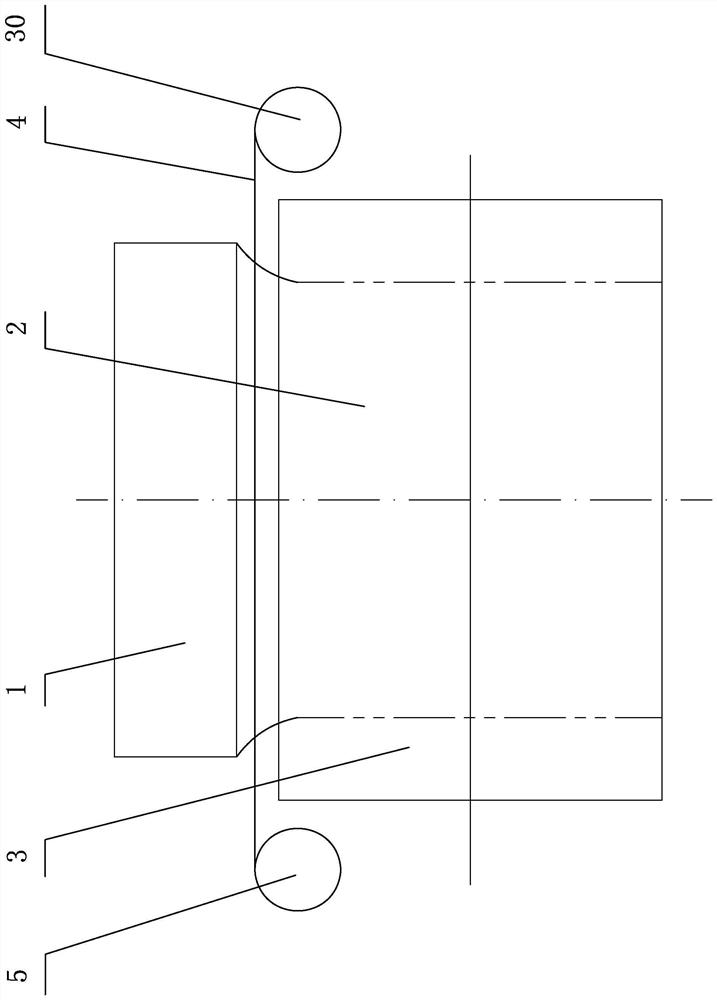

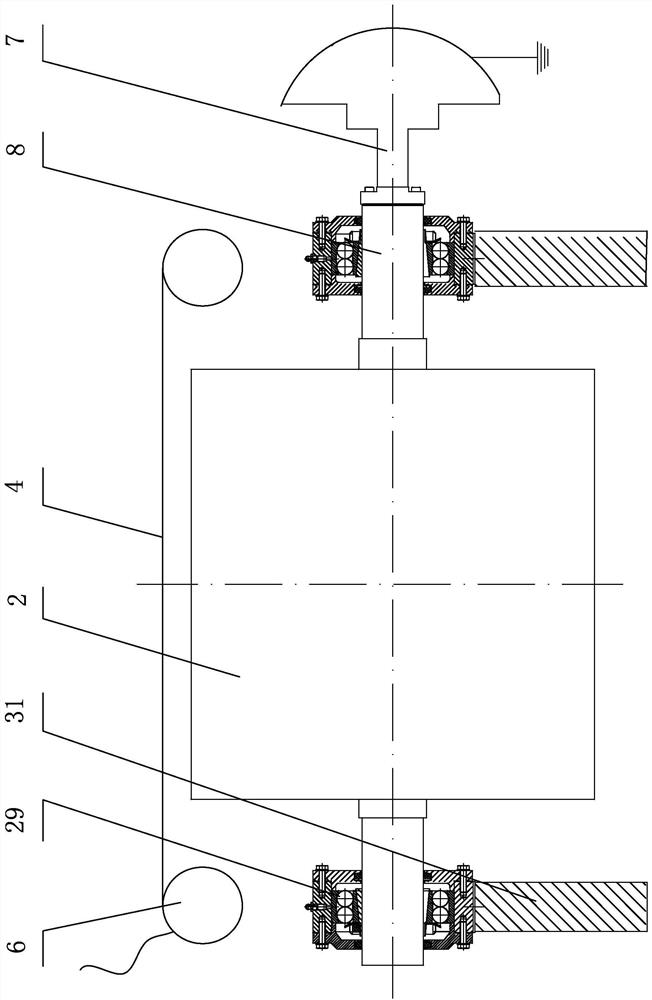

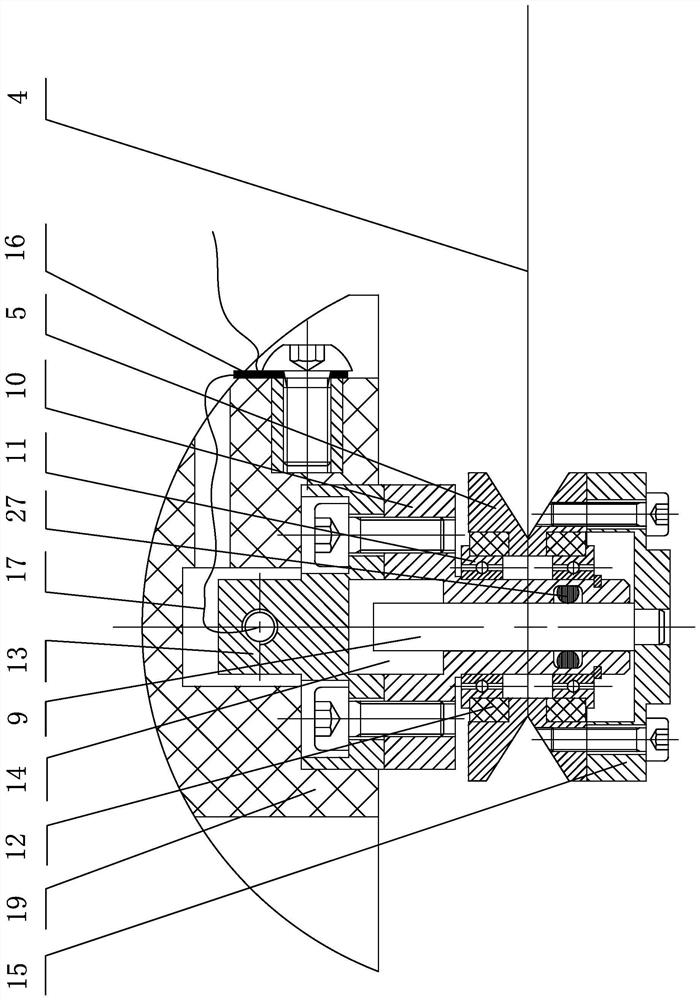

[0021] The polyester film electrostatic adsorption system of the present invention includes a high-voltage introduction device 6 connected to the winding wheel 5 on the left side and a grounding device 7 connected to the rotating shaft 8 on the right side, and the electrode wire 4 is wound on the winding wheel 5 and the right side. On the right guide wheel 30 on the side and horizontally arranged between the die head 1 and the cold drum 3, the left and right rotation shafts 8 of the cold drum 3 are installed on the left and right pillars 31 through the left and right bearing mechanisms 29 The main circuit of the corona current is that the DC high voltage U of the high-voltage generator is introduced on the electrode wire 4 through the winding wheel 5, thereby generating corona, and the corona charge is transferred from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com