Electronic device and process of forming the same

A technology of electronic devices and terminals, which is applied in the field of electronic devices and their formation, and can solve the problem of difficulty in controlling the shape of the field stop region

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0061] Embodiment 1. An electronic device which may comprise:

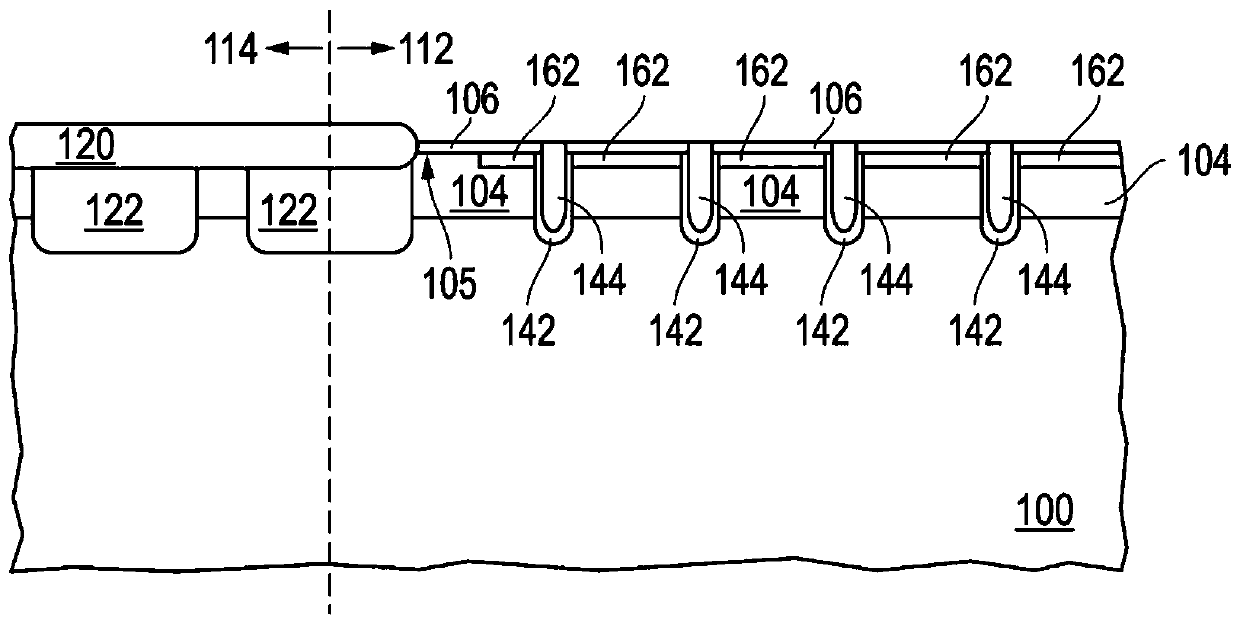

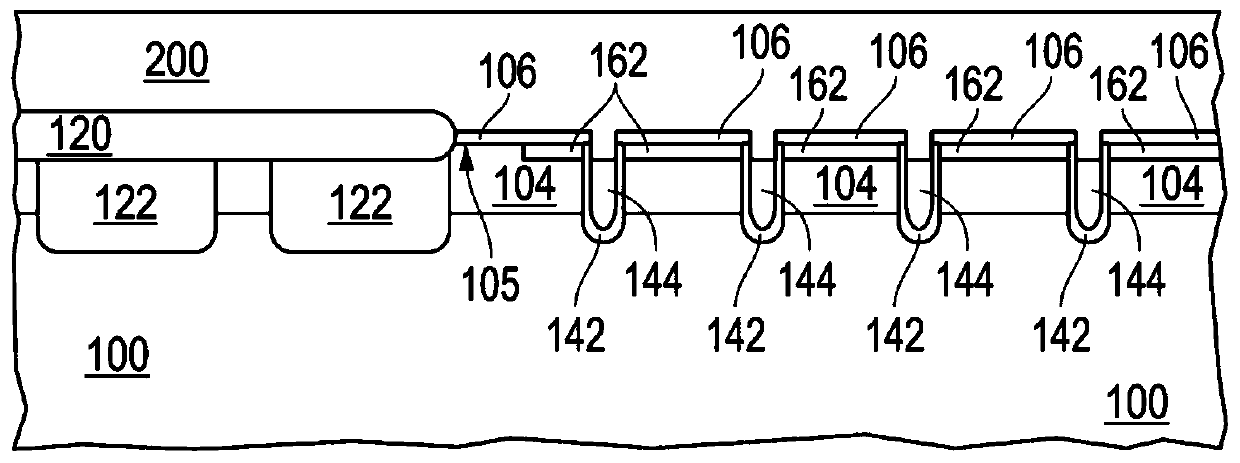

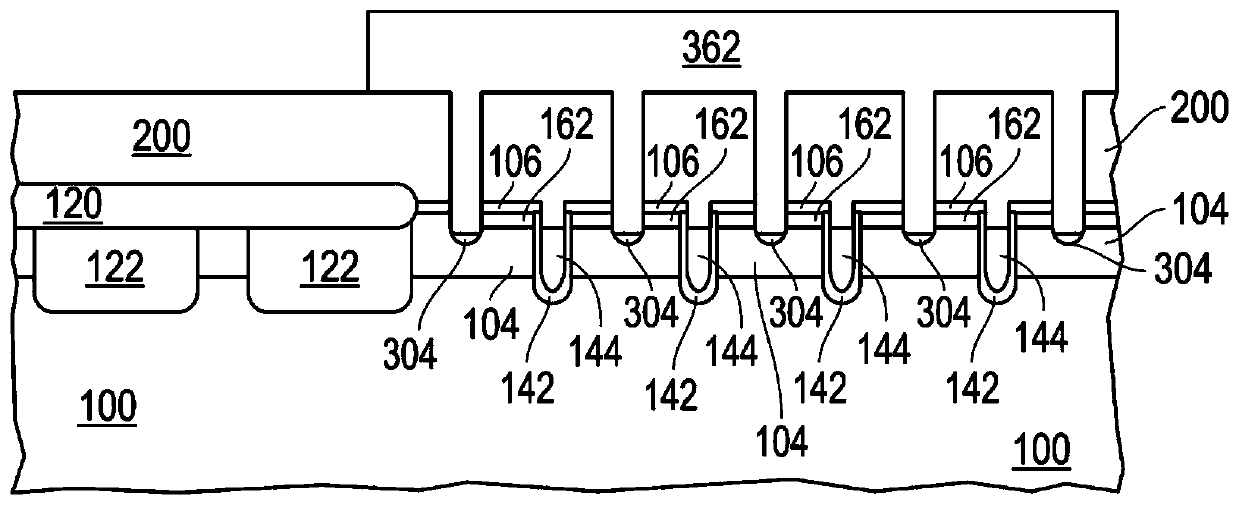

[0062] A semiconductor substrate having a first main side, a second main side opposite the first main side, and a second main surface along the second main side;

[0063] an emitter region closer to the first main side than to the second main side, wherein the emitter region has a first conductivity type;

[0064] a trench extending from the second main surface into the semiconductor substrate, wherein the trench has sidewalls and a bottom;

[0065] a collector region spaced along the second major surface and from the bottom of the trench, wherein the collector region has a second conductivity type opposite the first conductivity type;

[0066] a field stop region disposed along at least a portion of the bottom and sidewalls of the trench, wherein the field stop region has the first conductivity type; and

[0067] A collector terminal along the second major side and comprising a metal-containing material, wherei...

Embodiment approach 2

[0068] Embodiment 2. The electronic device of Embodiment 1, further comprising an insulating layer disposed along sidewalls and a bottom of the trench, wherein the insulating layer is disposed between the field stop region and the collector terminal.

Embodiment approach 3

[0069] Embodiment 3. The electronic device of Embodiment 2, wherein the insulating layer substantially fills the trench.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com