Sounding device and electronic terminal

A sounding device and combined technology, applied in the direction of electrical components, telephone structures, electromechanical sensors, etc., can solve the problems of increasing the pulling force of the front cover and the shell, long design and change cycle, high cost, etc., to achieve superior sealing performance, Simple molding and improved pull-out force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

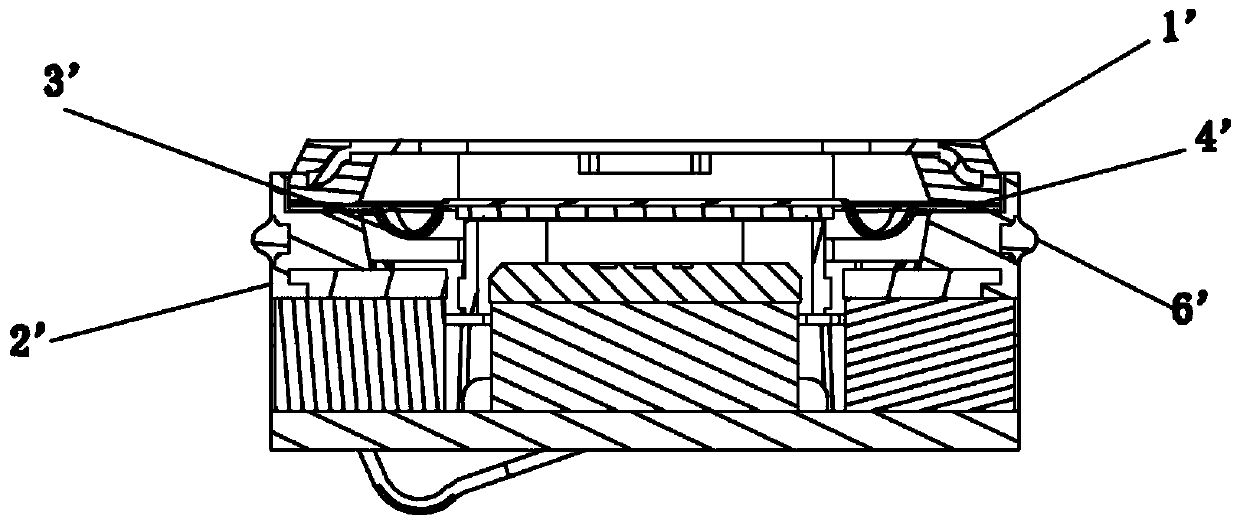

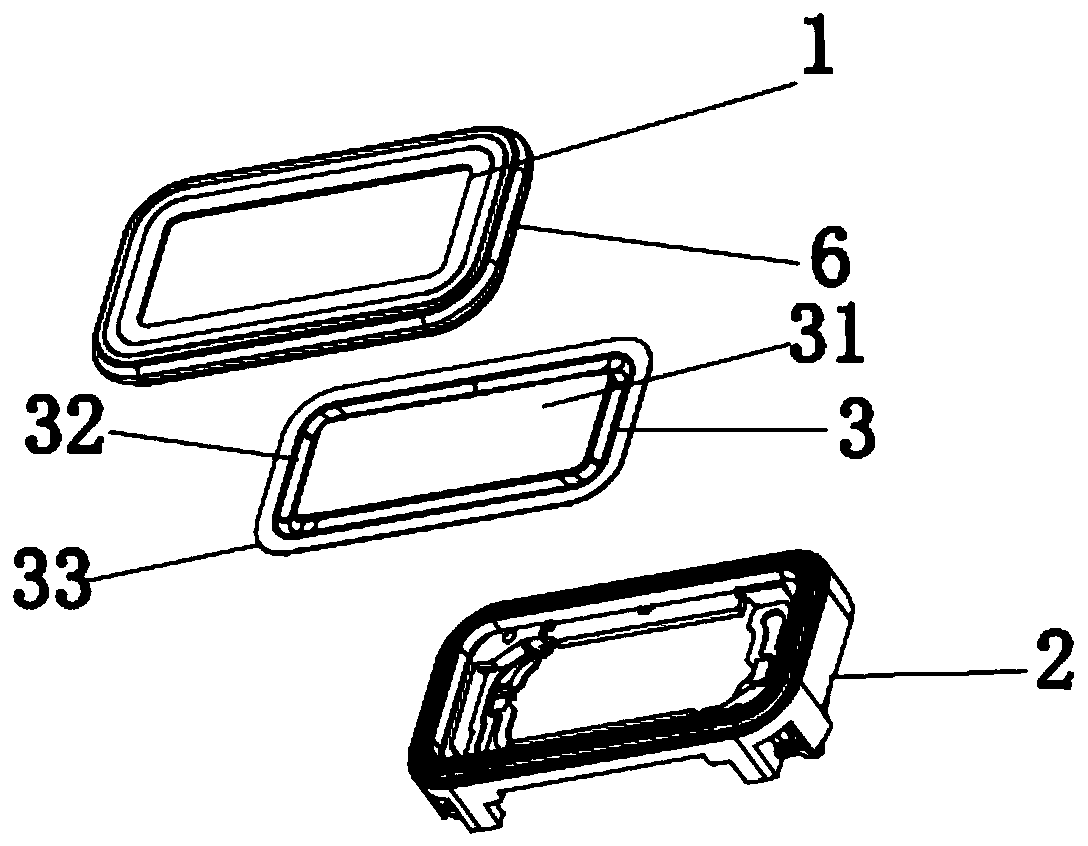

[0046] see image 3 , Figure 4 and Figure 5Commonly shown, a sounding device is provided, which specifically includes a front cover 1 and a housing 2 that are combined together. The cavity surrounded by the front cover 1 and the housing 2 accommodates a diaphragm 3, and the front cover 1 is far away from the diaphragm 3. The surface is covered with an elastic seal 6 , and the elastic seal 6 is integrated with the front cover 1 .

[0047] Specifically, the upper surface of the front cover 1 away from the diaphragm 3 is covered with an elastic seal 6. The present invention arranges the elastic seal 6 on the front cover 1. On the one hand, the elastic seal 6 can realize the sealing of the sound-generating device and improve the sound quality. The sealing and waterproofing of the sounding device; on the other hand, when the sounding device is assembled into the electronic terminal, the assembly of the sounding device and the electronic terminal is realized by compressing the e...

Embodiment 2

[0056] Compared with the first embodiment, this embodiment has the same point, the first glue-coating area 41 is set at the junction of the front cover 1 and the edge part 33 of the diaphragm, the difference is that in this embodiment, the concave part 421 is disposed on the housing 2 , the protruding portion 422 is disposed on the front cover 1 , the protruding portion 422 is inserted into the recessed portion 421 , and is fixed together by the glue in the recessed portion 421 . In fact, the main function of this part of the design is equivalent to the design of the second glue application area 42 in the first embodiment.

[0057] As mentioned in the first embodiment, the joints of the front cover 1 , the casing 2 and the edge portion 33 of the diaphragm are all provided with a first glue-receiving groove 51 , which will not be repeated here.

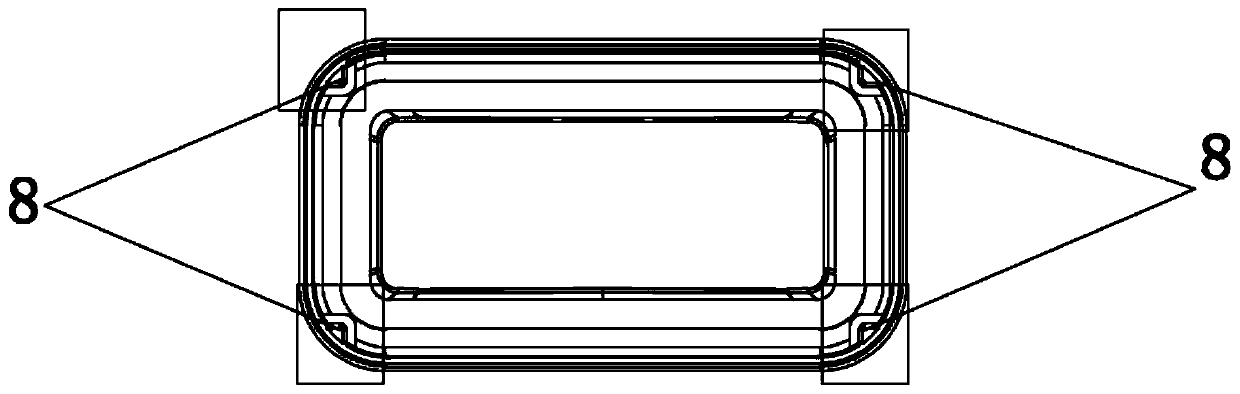

[0058] In addition to the setting of the above-mentioned gluing area and the gluing tank, in this embodiment, as Figure 8 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com