Clutch mechanism comprising two components connected by an assembly device

一种离合器机构、组装装置的技术,应用在机动车辆双离合器机构,机动车辆变速器领域,能够解决组装困难、复杂等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

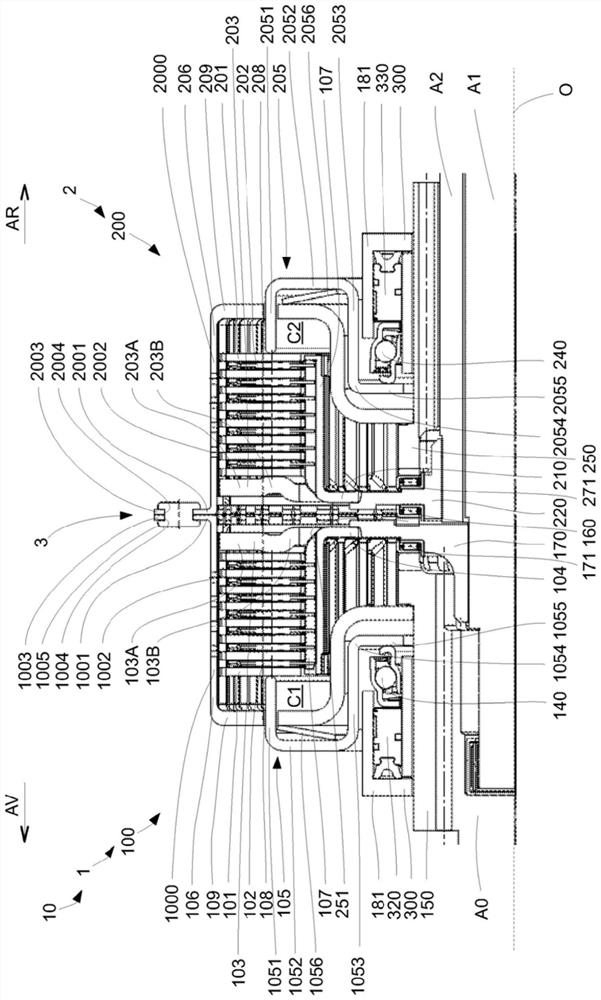

[0180] According to this first embodiment of the invention, the assembly device 3 comprises the outer disc support 106 of the assembly 1 formed by the first clutch 100 through a first extension 2003 facing the outer disc support 206 of the assembly 2 formed by the second clutch 200 Each pair of first extensions 1003, 2003 constituted by the first extensions 1003.

[0181] like figure 1 As shown, each first extension 1003 of the outer disc support 106 of the assembly 1 formed by the first clutch 100 includes an assembly hole 2004 with a first extension 2003 of the outer disc support 206 of the assembly 2 formed by the second clutch 200 Corresponding assembly holes 1004 . In each pair of first extensions 1003, 2003 as defined above, the rivet 1005 is intended to pass through the assembly hole 1004 in the first extension 1003 of the outer disc carrier 106 of the assembly 1 formed by the first clutch 100 and through The assembly hole 2004 in the first extension 2003 of the outer...

no. 4 example

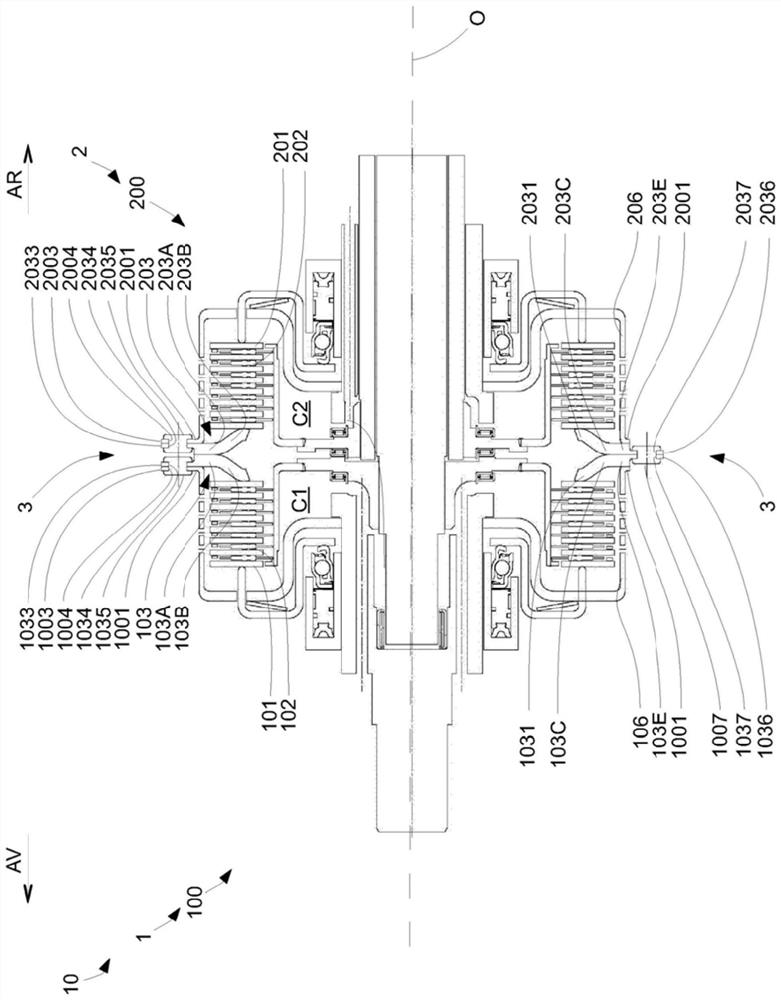

[0261] According to this fourth embodiment of the invention, the assembly device 3 comprises a second angular sector 1036, 2036 of one component 1, 2 of each pair and a second extension 1006, 2006 of the other component 1, 2, formed by the face A second angular sector 1036 of the reaction member 103 forming the component 1 of the first clutch 100 is formed to the second extension 2006 of the outer disc carrier 206 forming the component 2 of the second clutch 200 .

[0262] In the second angular sector 1036, 2036 of the assembly 1, 2 of each pair and the second extension 1006, 2006 of the other assembly 1, 2, the rivet 1009 is intended to pass through the reaction member 103 formed in the assembly 1, 2 The assembly aperture 1037, 2037 in the second angular sector 1036, 2036 of the first part 103A, 203A of , 203 and passes through the second extension 1006, 2006 formed in the outer disc support 106, 206 of the other assembly 1, 2 Assembly apertures 1038, 2038 in the second porti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com