Thin-wall high-rib wallboard component space envelope forming envelope die correction method

A wall plate and high-rib technology, which is applied in the field of enveloping mold correction of thin-walled and high-rib wall plate components, to achieve the effects of improving mechanical properties, reducing surface defects and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

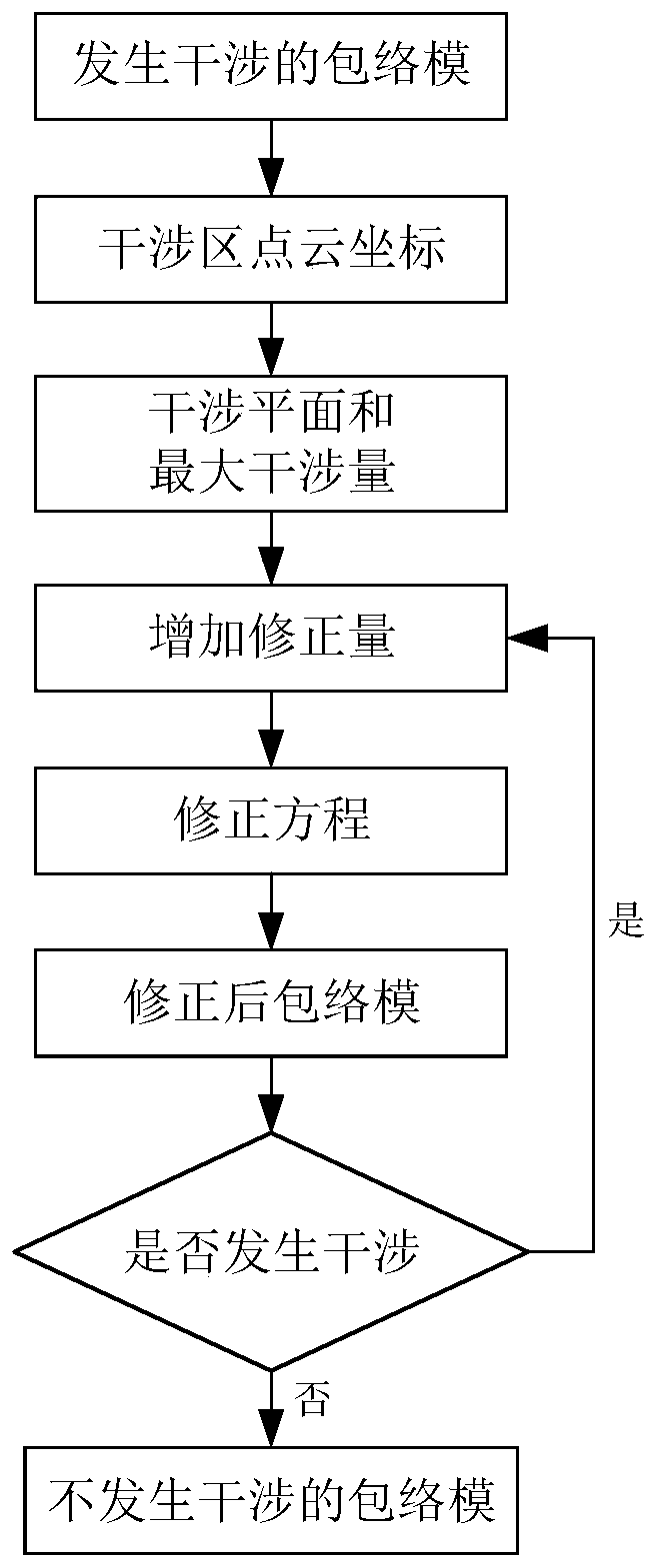

[0029] Such as figure 1 As shown, the thin-walled high-strength panel component space envelope forming envelope mold correction method of the present invention comprises the following steps:

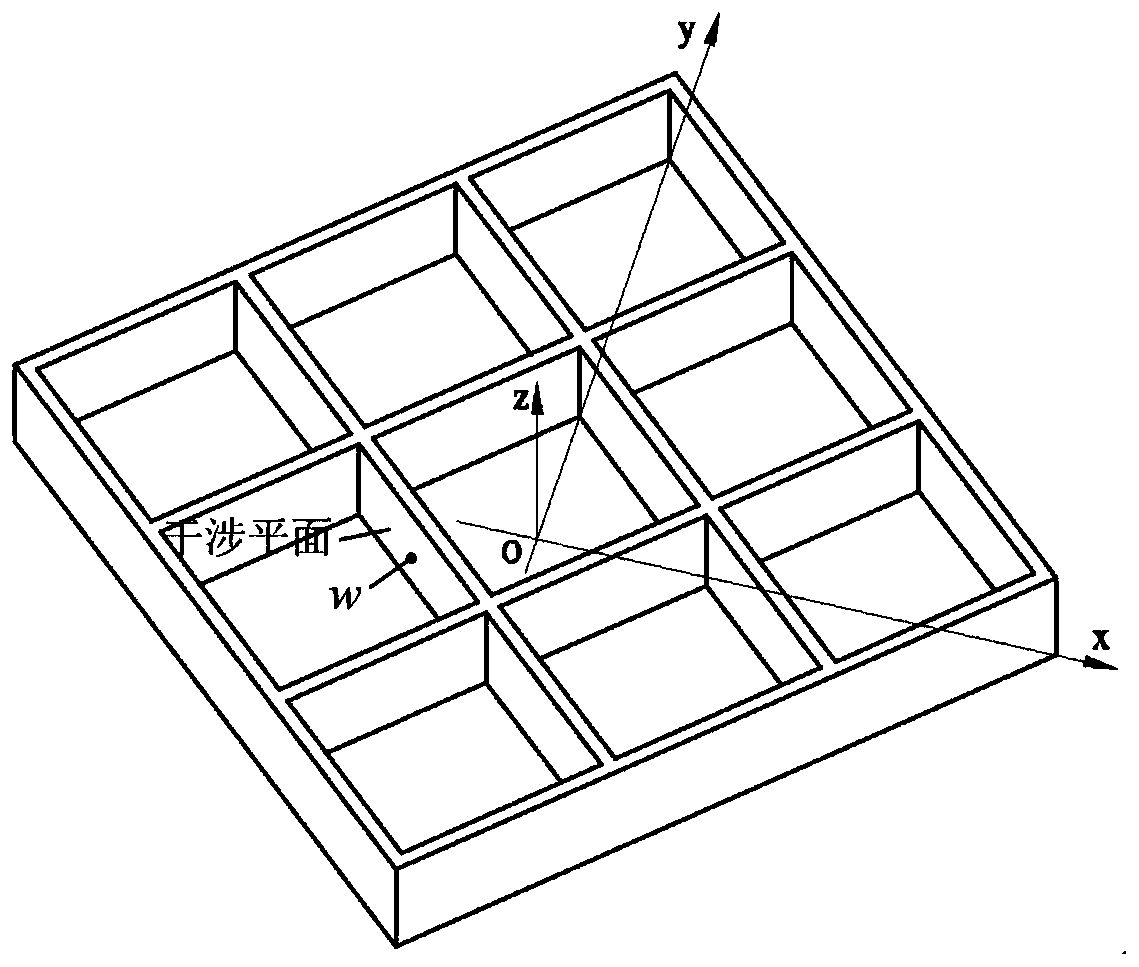

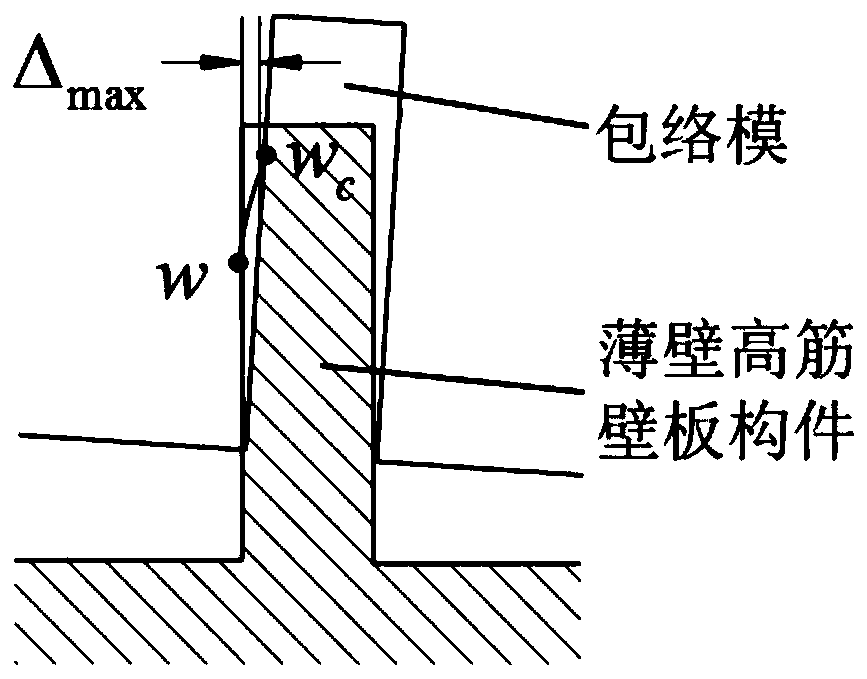

[0030] S1. Determine the correction principle of the envelope die for the space envelope forming of thin-walled and high-rib panel components. Calculate the maximum interference amount of each point in the interference area in the same specific rectangular coordinate system, and then determine the correction amount and correction equation of each point, and correct the envelope mode interference area through the correction equation. If the interference area cannot be completely eliminated, increase Correct the correction amount o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com