Locking device for foundry sand box

A technology of locking device and sand box, which is applied in the direction of casting molding equipment, molding box, manufacturing tools, etc., can solve the problems that affect the stability and service life of casting processing, the difficulty of removing nuts and screws, and the inability to continue to use. Achieve fast and effective separation, good practicability, and reasonable structure settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

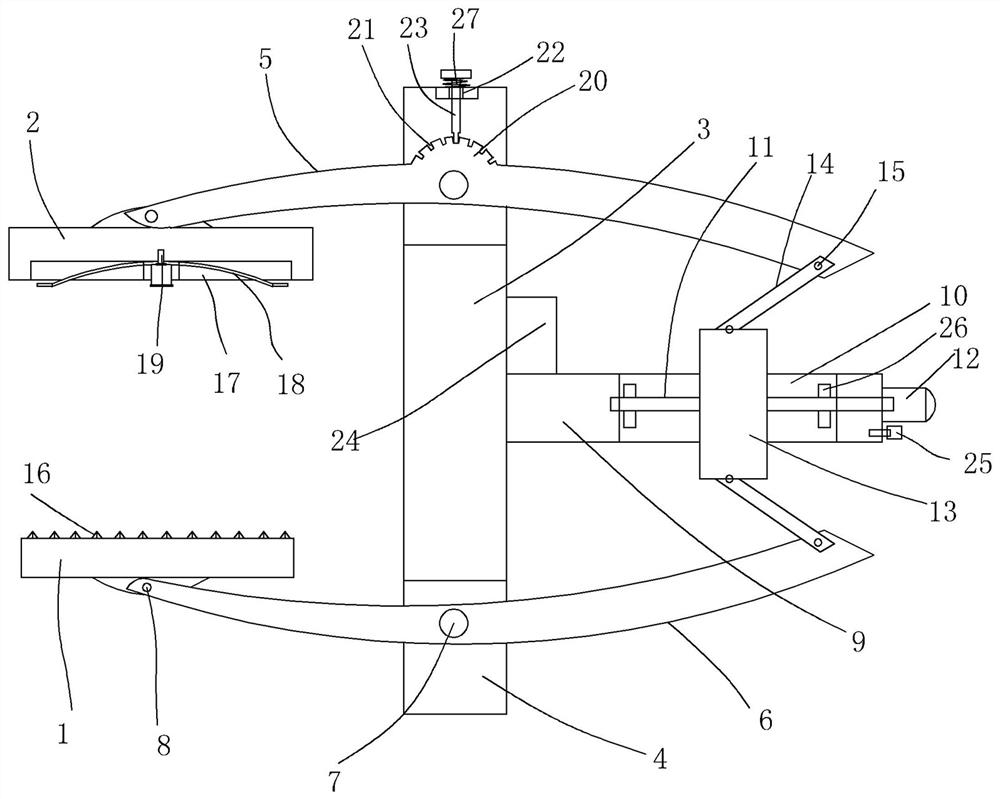

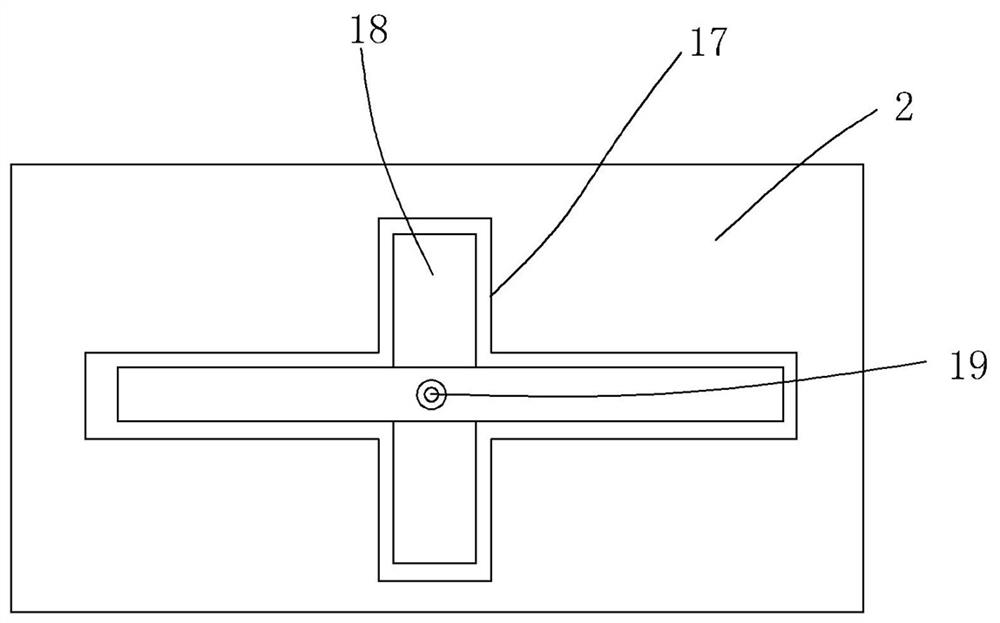

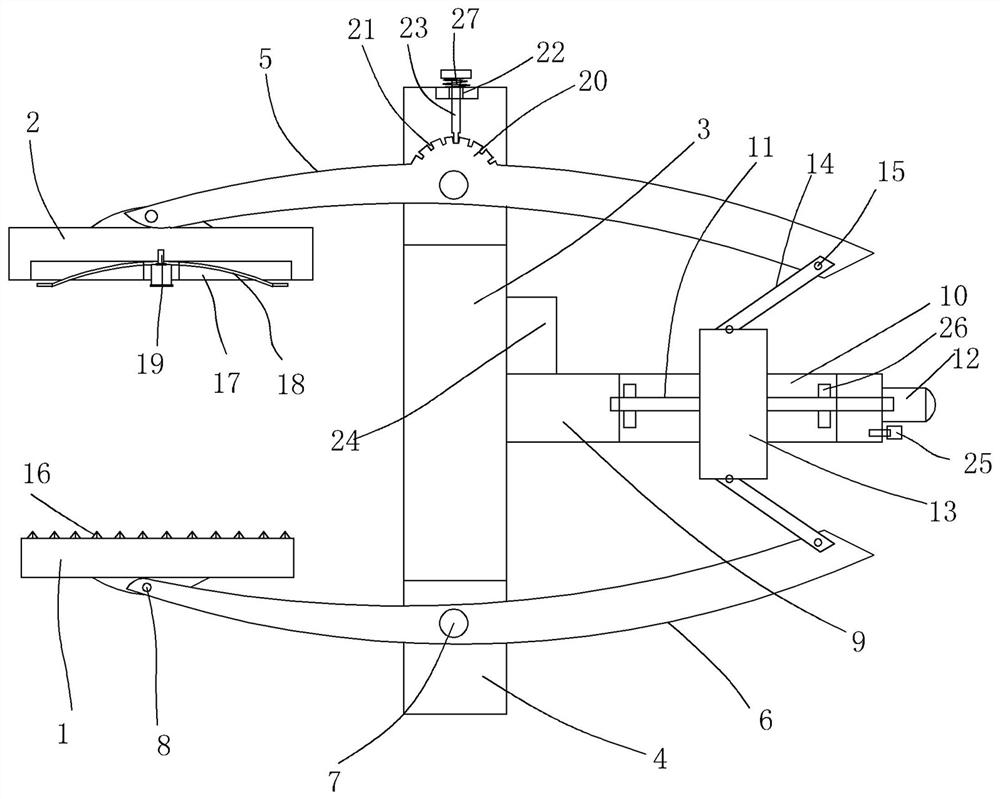

[0015] figure 1 and figure 2 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention; figure 2 It is a structural schematic diagram of another viewing angle of the clamping platen in the present invention.

[0016] See figure 1 and figure 2 , a locking device for a foundry flask, comprising a load-bearing bottom plate 1 for pressing against the bottom of the lower flask and a clamping plate 2 for clamping and pressing on the top of the upper flask, and a vertical strut 3 is also provided. The bottom surface and the top surface of the vertical struts are all provided with strip-shaped grooves 4, and the top and bottom of the vertical struts are respectively provided with upturned rods 5 and downturned rods 6, and the upturned rods and downturned rods The middle part of the rod is respectively connected in the strip-shaped grooves on the top surface and the bottom surface of the vertical support rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com