Automatic separating device for wallboard mould car

An automatic separation and mold car technology, applied in transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of reducing the working efficiency of mold cars, rare separation devices, etc., to achieve simple structure, stable work, and improved production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

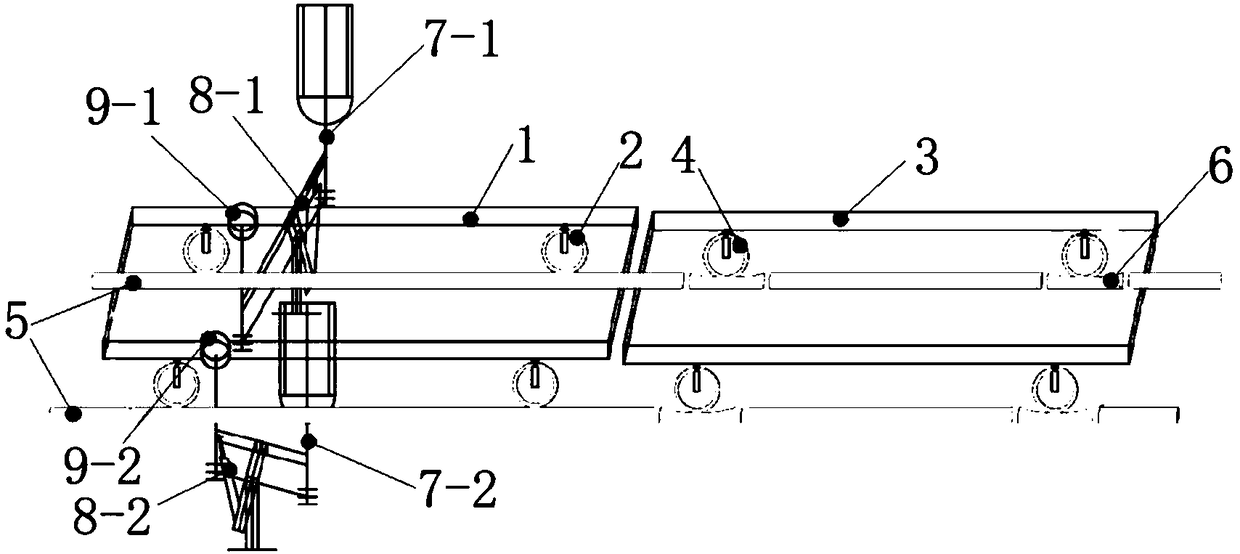

[0010] Such as figure 1 As shown, in the preferred embodiment of the automatic separation device for a wallboard mold car of the present invention, it includes a first mold car, a second mold car, a track (5), and a foot seat collinear with the track (5) (6) The first drive device and the second drive device are respectively arranged on the track (5).

[0011] In a preferred embodiment of the automatic separation device for wall panel mold vehicles in the present invention, the first mold vehicle includes a first vehicle body (1) and four The first wheel (2); the first mold car includes a second car body (3) and four second wheels (4) arranged at four corners of the bottom of the second car body (3).

[0012] In a preferred embodiment of the automatic separation device for wallboard mold vehicles in the present invention, the first driving device includes a first driving motor (7-1), a first transmission device (8-1), a first transmission wheel (9-1); the second driving devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com