Spring clamp used for feeding

A fixture and clamping technology, which is applied in the field of spring fixtures, can solve the problems of high production cost and complex structure, and achieve the effects of small use space, improved matching degree, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

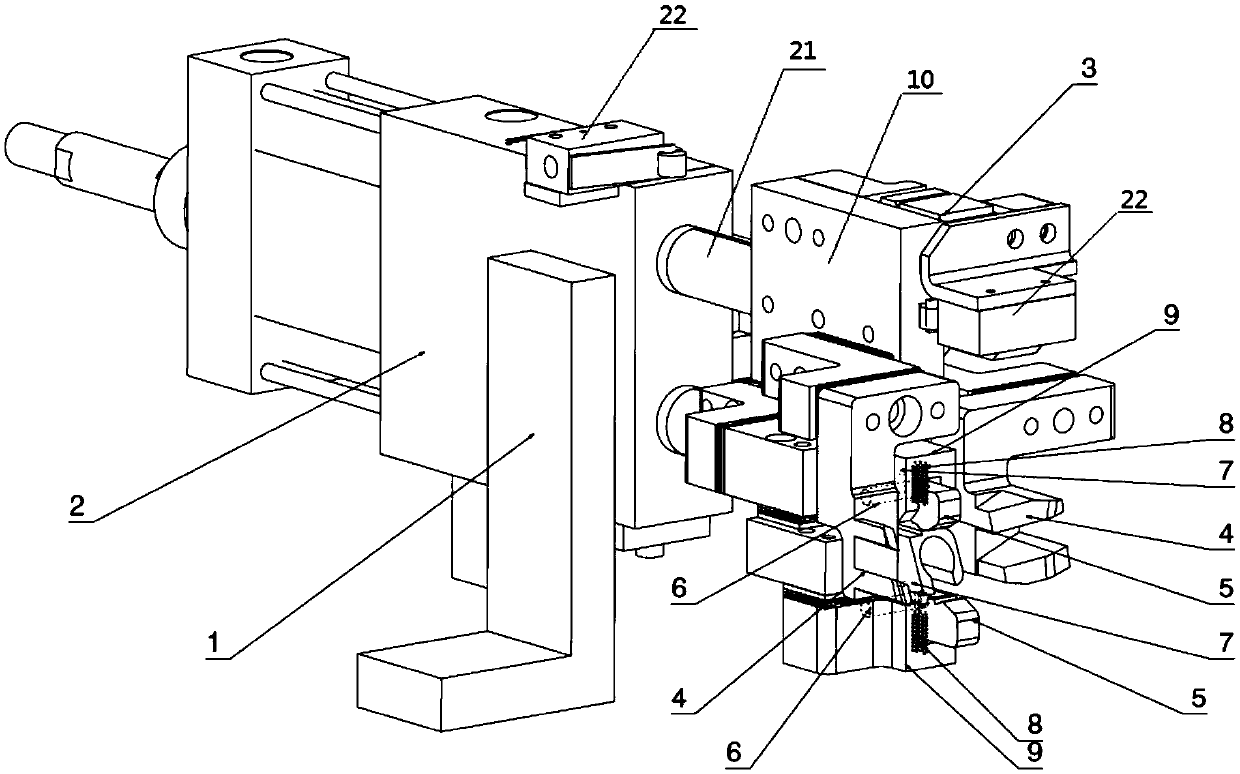

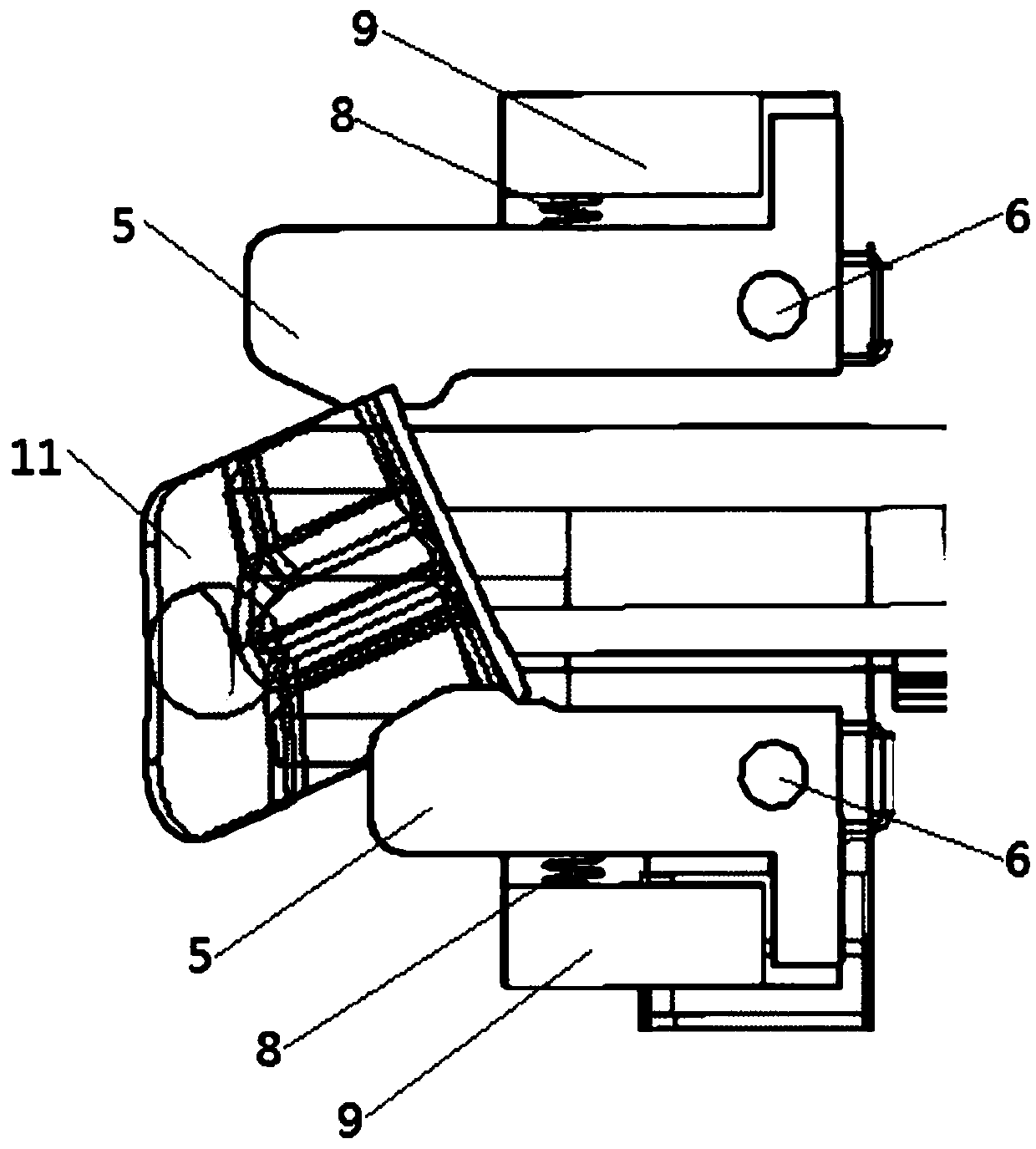

[0035] refer to figure 1 , figure 2 , a spring clamp used for the upper part, used for clamping and positioning the sheet metal parts 11, including a cylinder 2, a guide rod 21 protrudes from the cylinder 2, and the guide rod 21 is connected with a clamp for clamping and positioning the sheet metal parts For the clamping module, the guide rod 21 drives the clamping module to move telescopically.

[0036] The clamping module includes a spring base 9, a clamping block 5 and a supporting block 4. The clamping block 5 is connected to the spring base 9 through a latch 6. The clamping block 5 is used to clamp the sheet metal. A spring 8 is arranged between 5 and the spring base 9. The spring 8 is used to provide the force for the clamping block 5 to rotate on the spring base 9 around the latch 6. The support block 4 is used to support the sheet metal parts. The clamping module also includes A connection plate 10 connected to the guide rod 21 , the spring base 9 and the support bl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap