A double-head vegetable cutter

A vegetable cutting machine and body technology, applied in metal processing and other directions, can solve the problems affecting the efficiency of vegetable conveying, the speed of vegetable retention and other issues, and achieve the effect of convenient operation and guaranteeing conveying efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

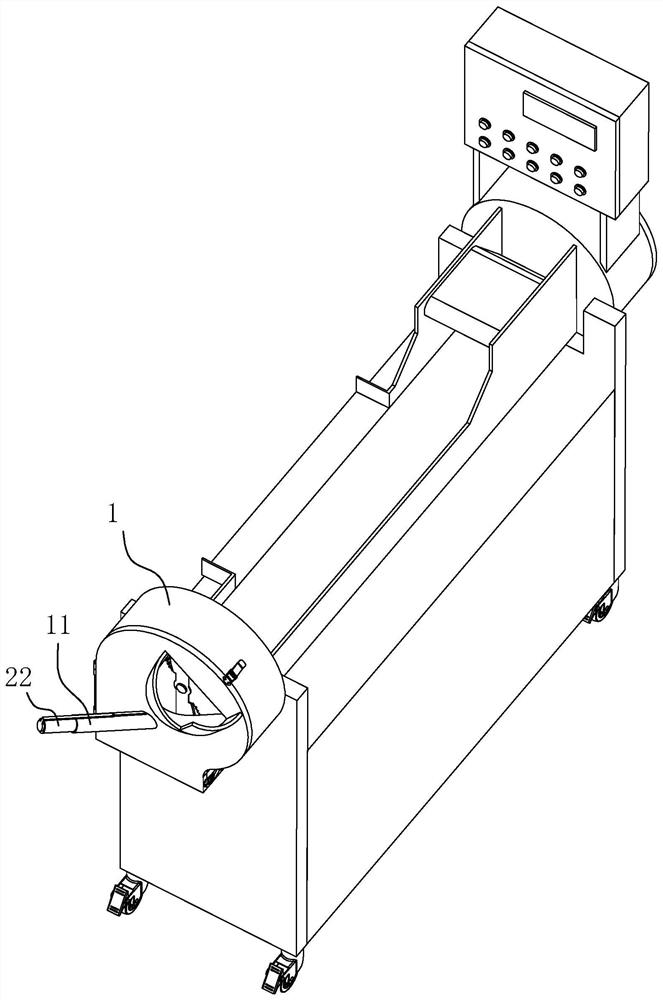

[0041] A double-head vegetable cutter, refer to figure 1 , which includes a body 1, the end wall of the body 1 is penetrated and welded and fixed with a feeding pipe 11, and the feeding pipe 11 is communicated with the inner cavity of the body 1.

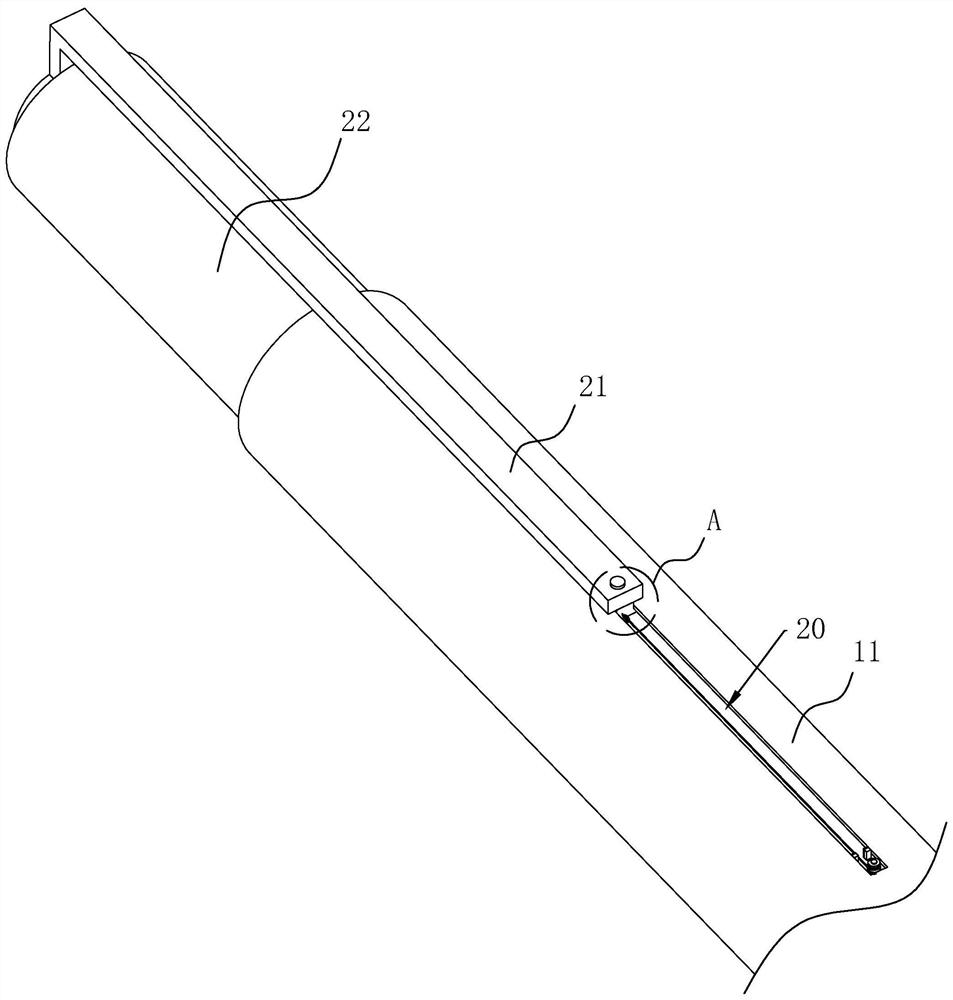

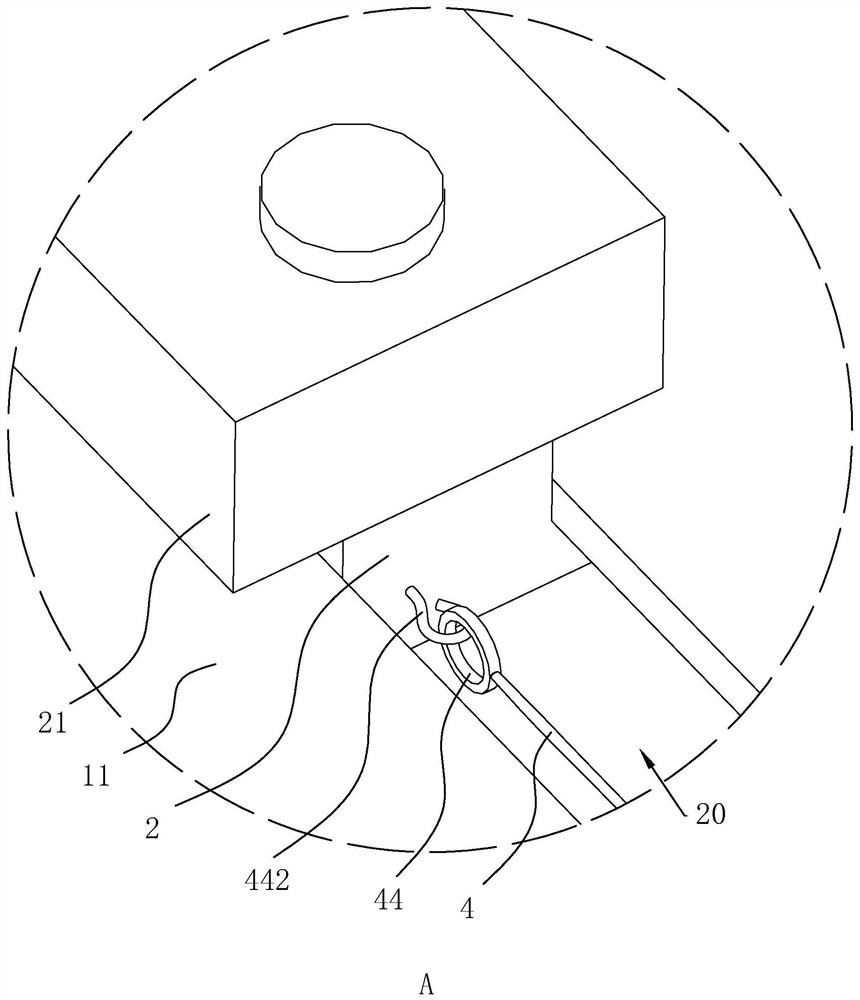

[0042] refer to figure 2 and image 3 , the side wall of the feeding pipe 11 is provided with a chute 20, a sliding block 2 is fitted in the chute 20, and the sliding block 2 is a T-shaped block. The connecting rod 21, the end of the connecting rod 21 facing away from the slider 2 is welded and fixed with a push rod 22, the push rod 22 can be inserted with the slider 2 or pulled away from the feed pipe 11, and the push rod 22 is pulled away from the feed pipe After 11, it can be turned away from the opening of the feeding pipe 11 with the connecting rod 21, so as to facilitate feeding.

[0043] refer to image 3 , an elastic cord 4 is connected between the inner wall of the chute 20 and the slider 2, and the elastic cord 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com