A production line of multi-purpose concrete prefabricated components and its application method

A prefabricated component and concrete technology, applied in manufacturing tools, ceramic molding machines, ceramic molding workshops, etc., can solve the problems of large impact on production line capacity, low production efficiency, low operating efficiency, etc. Reasonable and ingenious, high effective utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

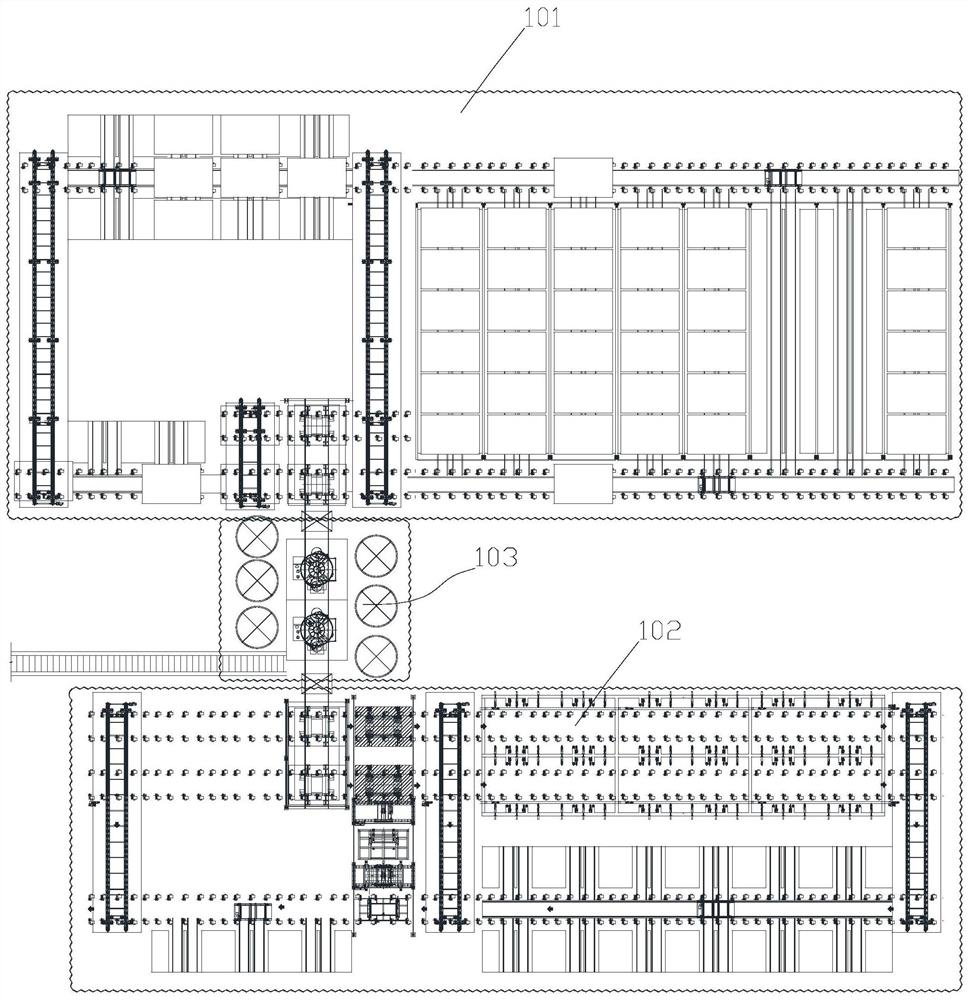

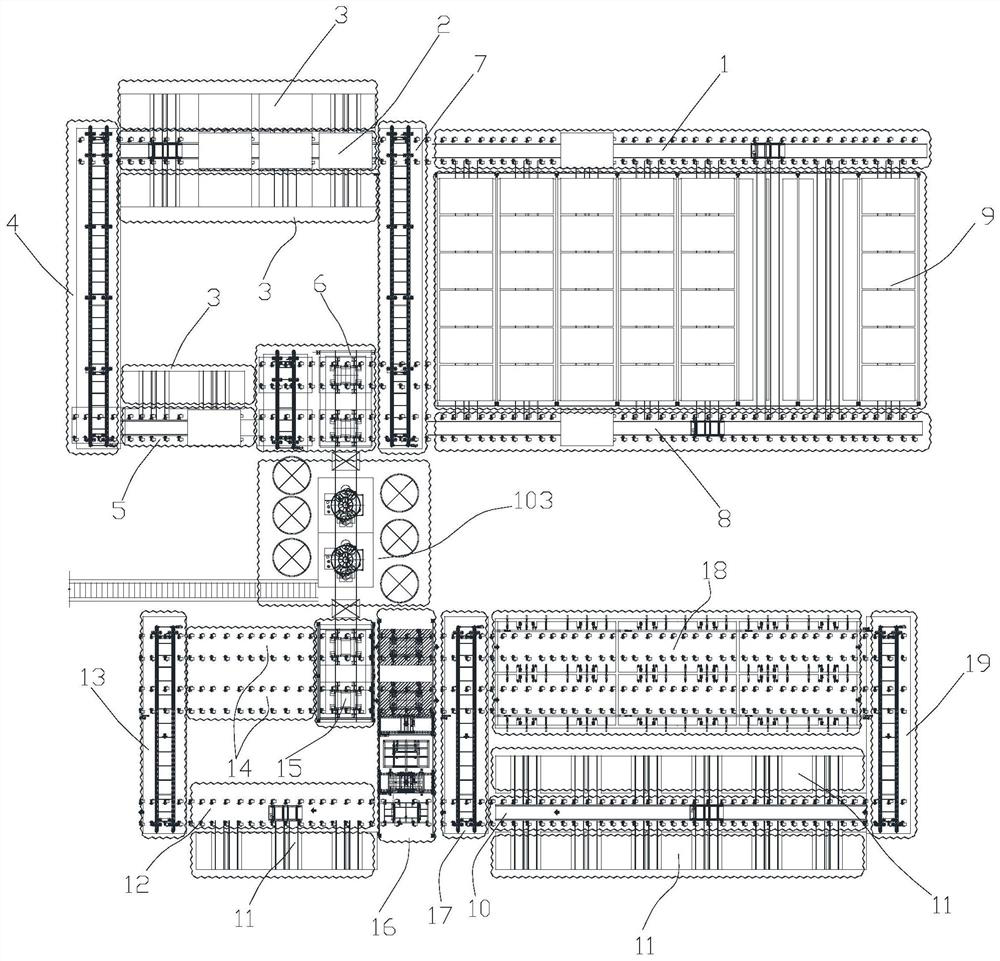

[0040] Examples, see figure 1 , a multi-purpose concrete prefabricated component production line provided in this embodiment, which includes a special-shaped component operation area 101, a panel component operation area 102, and the mixers provided in the concrete mixing operation area 103 supply concrete to the two operation areas respectively;

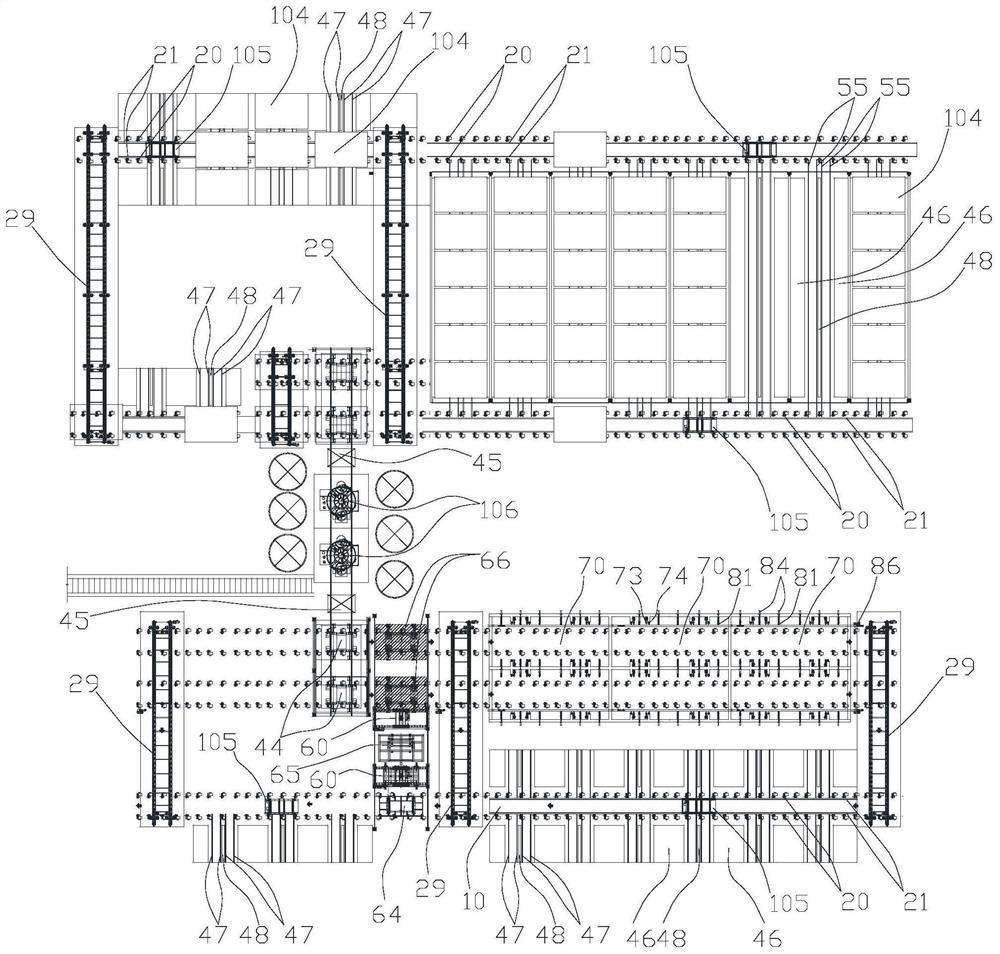

[0041] see figure 1 and figure 2 , a multi-purpose concrete prefabricated component production line provided in this embodiment, within the scope of the special-shaped component operation area 101, includes a longitudinal mold delivery roller channel 1 at the kiln outlet end, and includes a first empty mold operation longitudinal mold delivery roller channel 2, Including the second empty mold operation longitudinal mold conveying roller channel 5 and the end mold lateral movement channel of the special-shaped member working area connecting the first empty mold operating longitudinal mold conveying roller channel 2 and the second e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com