Concrete mixture for PHC (Prestressed High-strength Concrete) pipe pile and PHC pipe pile prepared therefrom

A technology for PHC pipe piles and concrete, applied in the field of concrete mixture and PHC pipe piles prepared therefrom, can solve the problems of unfavorable concrete durability, unfavorable building durability, low degree of automation, etc., and achieve excellent slump The effect of maintaining performance, eliminating the need for high-pressure steaming process, and improving the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with specific examples. It should be noted that the following examples are only further descriptions of the present invention, and should not be construed as limiting the protection scope of the present invention.

[0032] (1) Preparation of mineral admixture

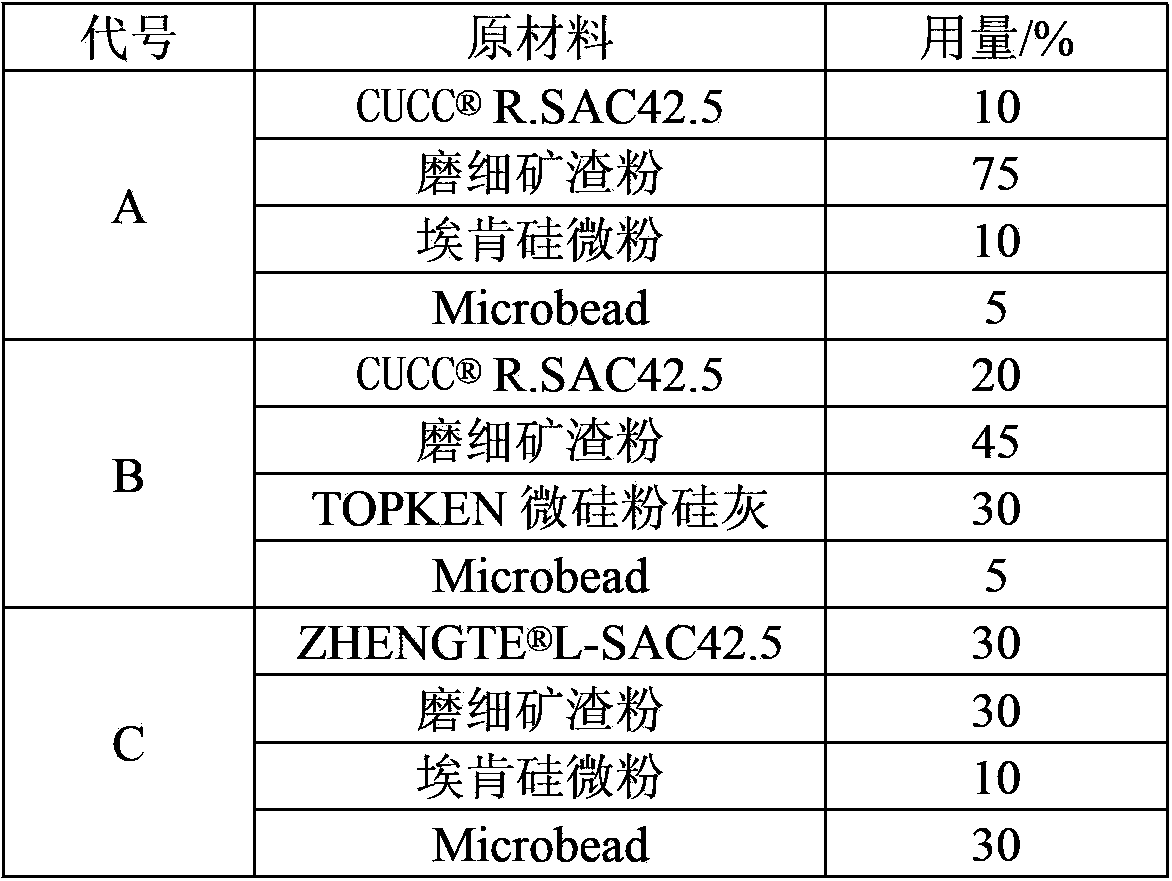

[0033] Examples of mineral admixtures are in accordance with Table 1, and the ratios listed in the table are all mass percentages.

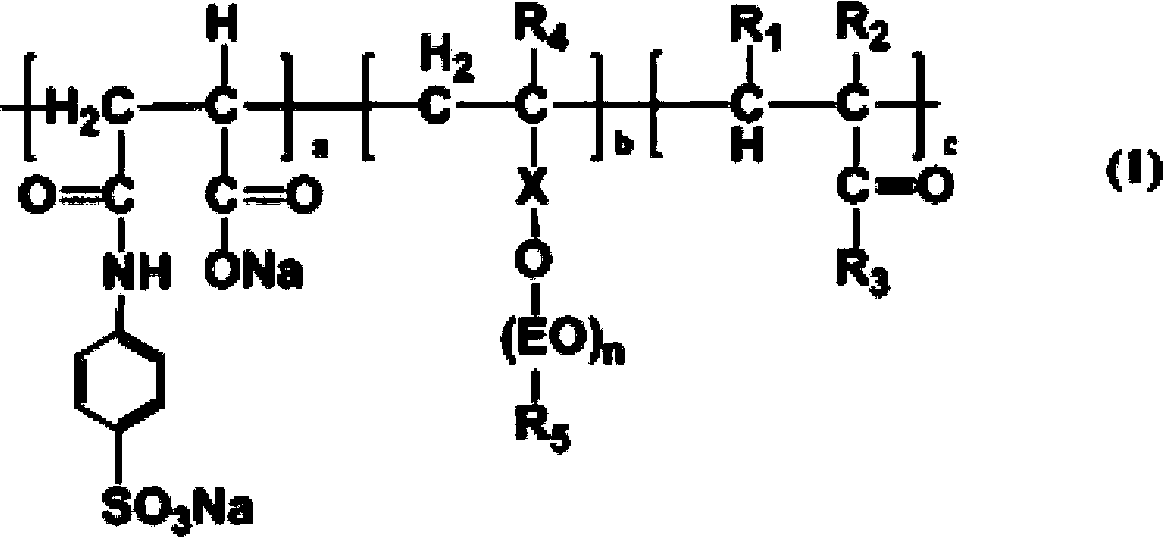

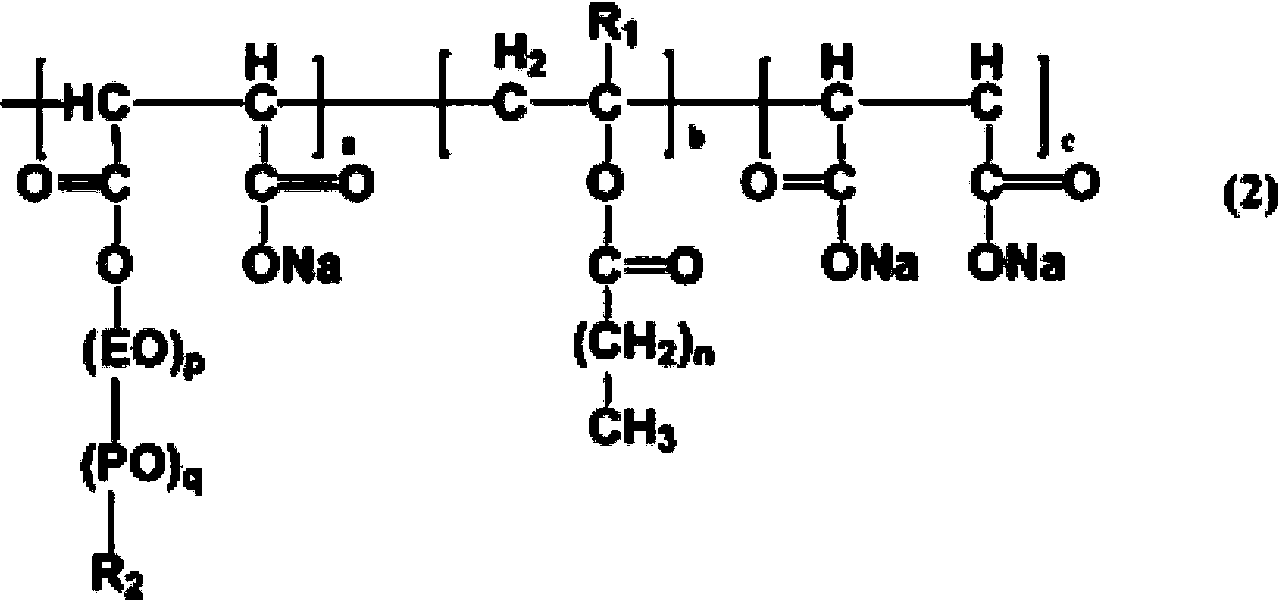

[0034] The calcium sulfoaluminate mineral in each case is or The silica fume has an average particle size of 0.1-0.3um and a specific surface area of 13-28m 2 / g, is Elkem silicon powder or TOPKEN micro-silica powder produced by Shanghai Tiankai Silica Material Co., Ltd.; the average particle size of the fly ash micro-beads is less than 1um, which is the product of Shenzhen Tongcheng New Material Technology Co., Ltd. Microbead ; The ground slag powder should meet the S95 standard in GB / T18046-2008, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com