A multi-beat screw counting machine and screw counting feeding method

A counting machine and screw technology, which is applied in the field of multi-beat screw counting machine and screw counting feeding, to achieve the effect of reducing the sticking rate, reducing the counting error rate and preventing counting errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

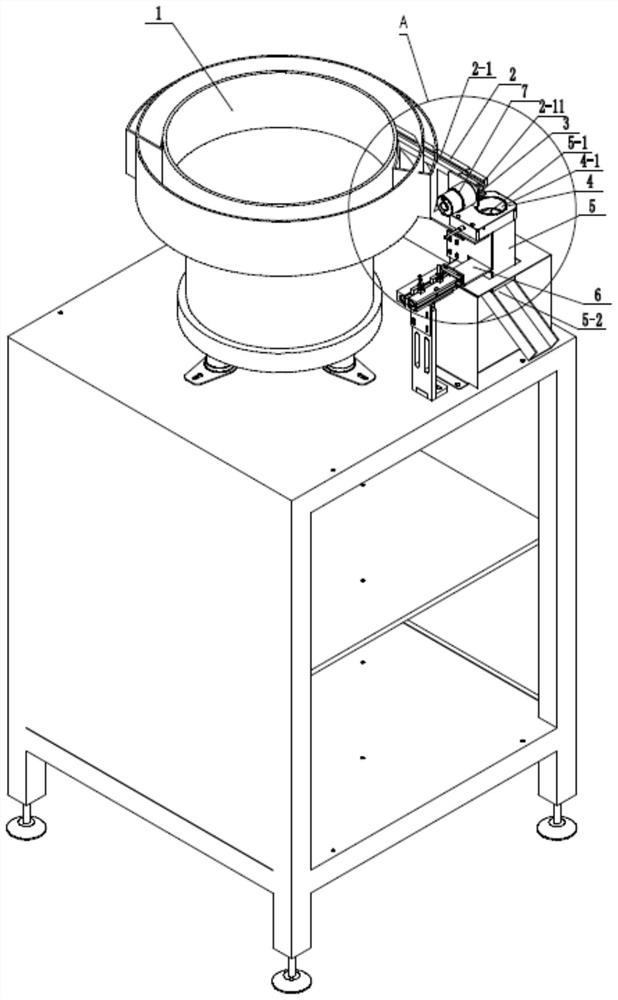

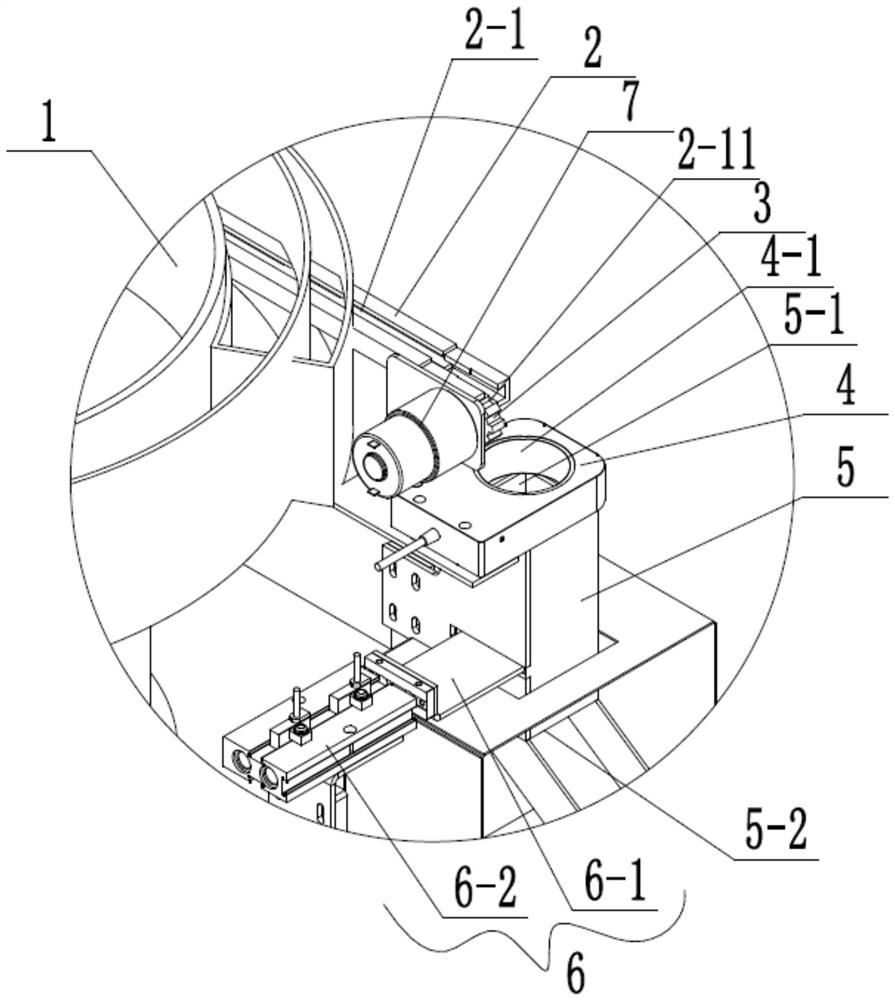

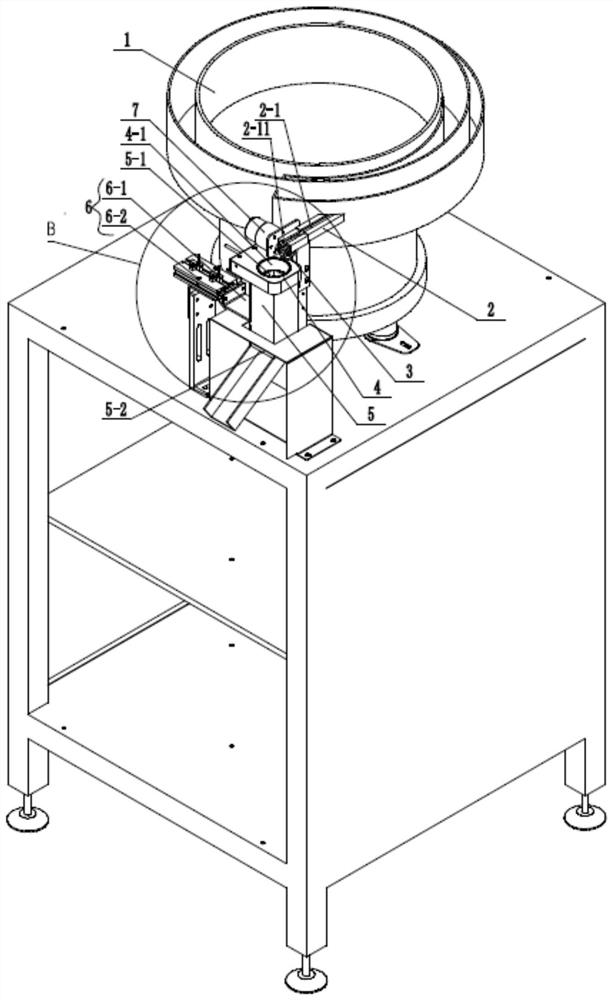

[0052] Embodiment one: see Figure 1-14 , a multi-beat screw counting machine, including a screw vibrating plate 1, a screw conveyor track 2, a distribution gear 3, an annular proximity sensor 4, a temporary storage bin 5 and a discharge switch valve 6.

[0053] Preferably, the screw vibrating plate 1 adopts an equally divided helical top plate. If you can choose the Hy-060 screw vibrating plate produced by Dongguan Hongyang Automation Equipment Co., Ltd. see Figure 1-4 One end of the screw conveying track 2 is connected to the outlet of the screw vibrating plate 1, the distribution gear 3 is arranged on the other end of the screw conveying track 2 and when the distribution gear 3 rotates, the screws at the other end of the screw conveying track 2 can be screwed one by one. Dial out; the distribution gear 3 is connected to the first rotary power source 7, and the first rotary power source 7 is used to drive the distribution gear 3 to rotate. Specifically, the screw conveyi...

Embodiment 2

[0074] Embodiment two: a screw counting feeding method, which uses the multi-beat screw counting machine described in embodiment one, the method includes the following steps:

[0075] S100, installing screws in the screw vibrating plate 1;

[0076] S200, set the screw feeding formula (specifically, four setting values 5, 4, 7, 3 can be input respectively through the touch screen); the screw feeding formula includes the number of screw feeding in the first beat (such as 5 screws) , The number of screw feeds in the second beat (such as 4 screws), the number of screw feeds in the third beat (such as 7 screws), the number of screw feeds in the fourth beat (such as 3 screws), and repeat the cycle in turn;

[0077] S310, the PLC controls the discharge switch valve 6 to start work and makes the discharge port 5-2 of the temporary storage bin 5 in a closed state (see Figure 10-11 );

[0078] S320, the PLC controls the screw vibrating plate 1 to start working, and the screw vibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com