Self-calibrating measuring device and portable testing instrument

A measuring device and self-calibration technology, applied to instruments, analytical materials, etc., to achieve the effects of prolonging service life, easy manufacturing and installation, and reducing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

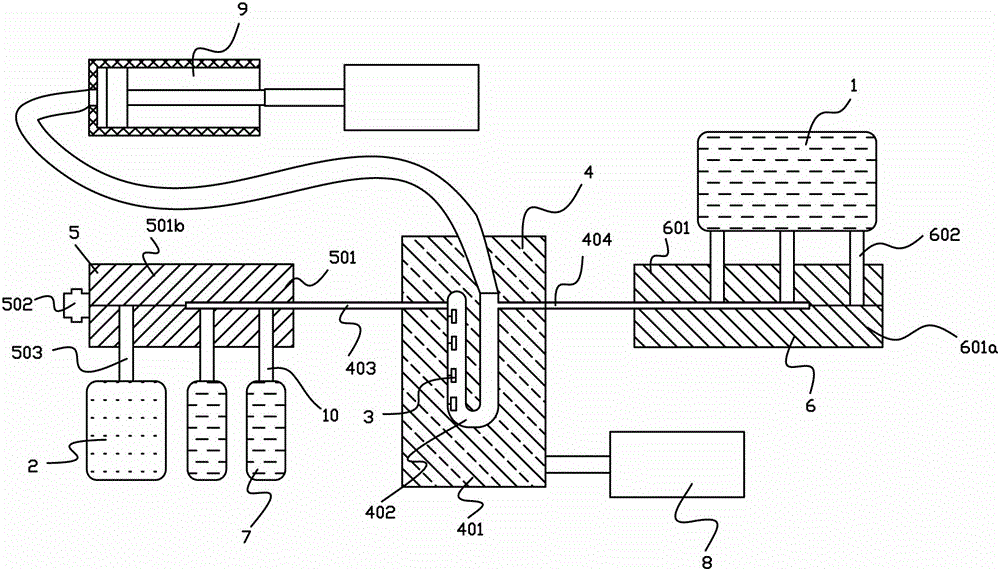

[0036] Embodiment 1, see attached figure 1 , 2 , a self-calibrating measuring device, the entire self-calibrating measuring device is set in a portable testing instrument to form a completed portable testing instrument, specifically, the self-calibrating measuring device includes a calibration liquid pool 1, a waste liquid pool 2, a detection sensor 3 and a mobile detection module 4. The size of the calibration liquid pool 1 and the waste liquid pool 2 is set according to actual needs, which can be two containers, or can be set on a container on the casing of a portable detection instrument. The mobile detection module 4 can move linearly, and is controlled by a linear motor 8 Driven, the linear motor 8 is arranged in the portable detection instrument, and when installing, between the mobile detection module 4 and the housing of the portable detection instrument, a linear guide pair or a similar structure is provided to guide the waste liquid pool 2 and the second The first f...

Embodiment 2

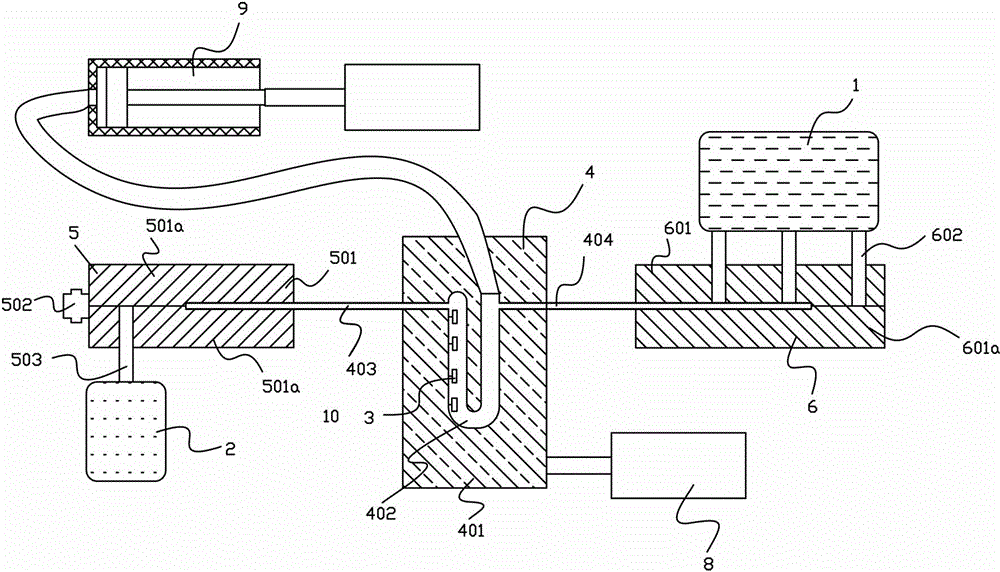

[0042] Embodiment 2, see attached figure 2, in this embodiment, the first elastic closure module 501 includes two first elastic blocks 501a made of elastic material, the elastic material can be polyurethane or elastic rubber, two adjacent elastic blocks 501a The sides are fitted together to form a fitting seam, and the fitting seam is aligned with the first capillary duct 403. Preferably, the middle position of the fitting seam is aligned with the first capillary duct 403. This fitting seam can make The first capillary guide tube 403 passes through, and when the first capillary guide tube 403 is located therein, it can be closed and not in a conducting state, and the detected liquid connection port 502 is arranged on the two first elastic blocks The end part of 501a is used for installing the sampling head, absorbing the liquid to be detected, and communicates with the bonding seam in the waste liquid channel 503, and it is provided with a sealing ring for sealing.

[0043] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com