Hole extrusion strengthening method of aluminum alloy thick plate and lubricant for said method

An aluminum alloy and lubricant technology, which is used in the field of hole extrusion strengthening of aluminum alloy thick plates and lubricants, can solve the problems of reduced extrusion strengthening effect, scratched hole walls, large extrusion force, etc., and achieves excellent reduction. Anti-wear performance, guaranteed effect, effect of uniform friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

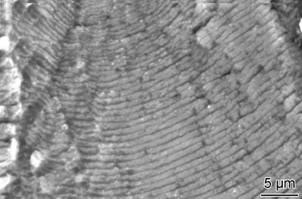

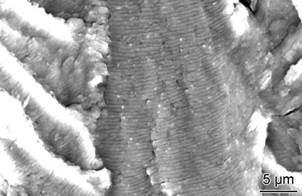

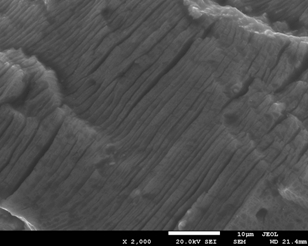

Image

Examples

Embodiment 1

[0093] Prepare lubricant.

[0094] The first lubricant comprises the following components in parts by mass:

[0095] 30 parts of flake graphite, 15 parts of tungsten disulfide, 22 parts of polyimide, 68 parts of epoxy resin, 80 parts of ethanol and 10 parts of xylene.

[0096] The second lubricant comprises each component of following mass parts:

[0097] 20 parts of flake graphite, 10 parts of tungsten disulfide, 22 parts of polyimide, 68 parts of epoxy resin, 80 parts of ethanol and 10 parts of xylene.

[0098] According to the raw material composition of the lubricant, epoxy resin and polyimide are dissolved in a solvent, then flake graphite and tungsten disulfide are added and ultrasonically dispersed to obtain a uniformly dispersed lubricant.

[0099] The lubricant of the embodiment of the present invention has the advantages of high load resistance, low friction coefficient, high toughness, high and low temperature resistance, etc., and also has excellent curing perfor...

Embodiment 2

[0102] Hole extrusion strengthening of 7050 aluminum alloy thick plate includes the following steps:

[0103] 1) Hole to be strengthened: the hole diameter is 10mm, the surface finish of the hole wall is Ra1.6, and the extrusion amount is 1%.

[0104] 2) Coat the first lubricant of Example 1 on the hole wall of the hole to be strengthened, and after the first lubricant is cured and dried, a first anti-friction coating with a thickness of 60 μm is formed; in the first anti-friction coating The second lubricant of Example 1 was coated on the layer, and the second lubricant was solidified and dried to form a second friction-reducing coating with a thickness of 50 μm.

[0105] 3) According to the HB / Z 170-2005 "Hole Extrusion Strengthening of Aeronautical Parts" standard, the hole to be strengthened is extruded and strengthened: insert the tapered metal core rod (extrusion rod) into the hole to be strengthened, and the metal core rod Mechanical pressure is applied at the end, so ...

Embodiment 3

[0107] Example 3 is basically the same as Example 2, except that in step 2), a commercially available graphite dry film for hole extrusion with a graphite mass fraction of 20% is used to replace the first lubricant, and after drying, a graphite film with a thickness of 60 μm is formed. For the anti-friction coating, replace the second lubricant with a commercially available graphite dry film for hole extrusion with a graphite mass fraction of 13%, and form a anti-friction coating with a thickness of 50 μm after drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com