Tracing screen pipe

A tracking and screen technology, which is applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc., can solve problems such as the inability to obtain accurate production and the inability to arrange sand control screens in the tracking unit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

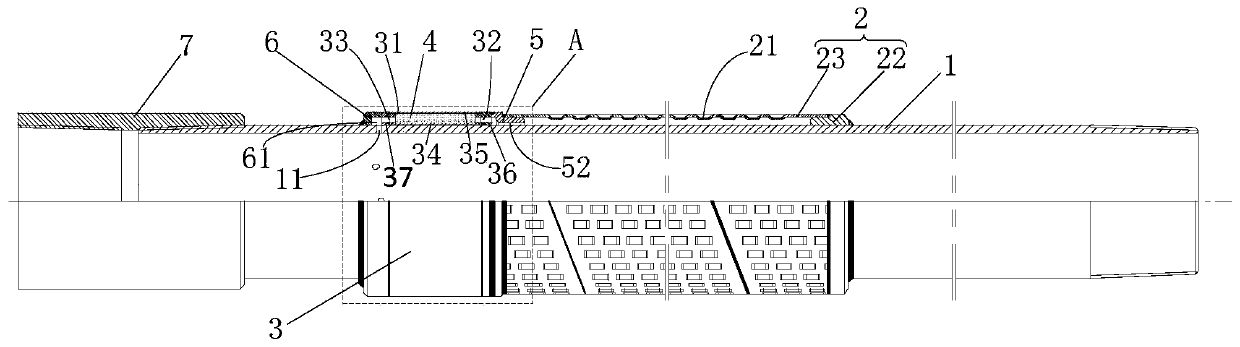

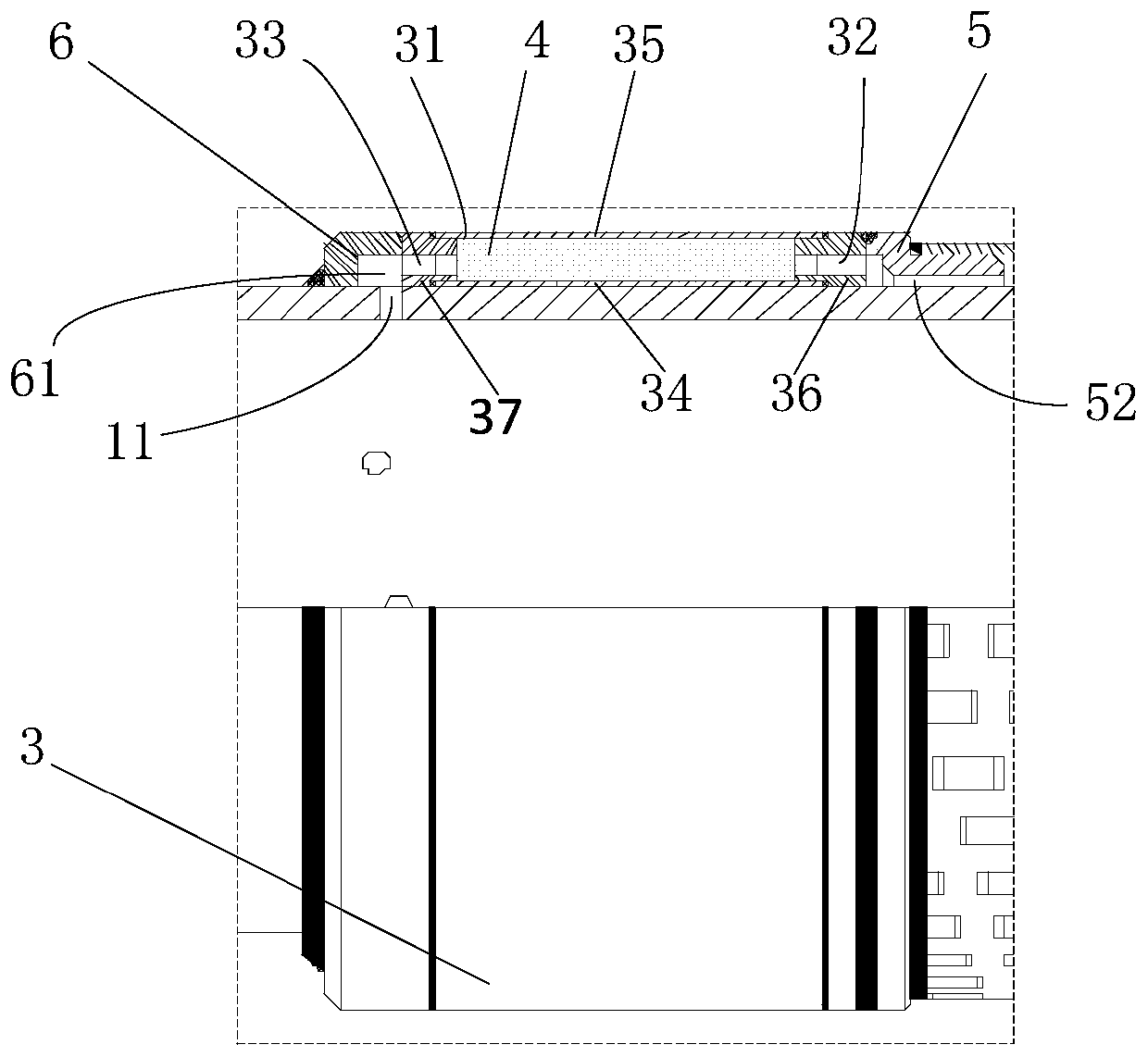

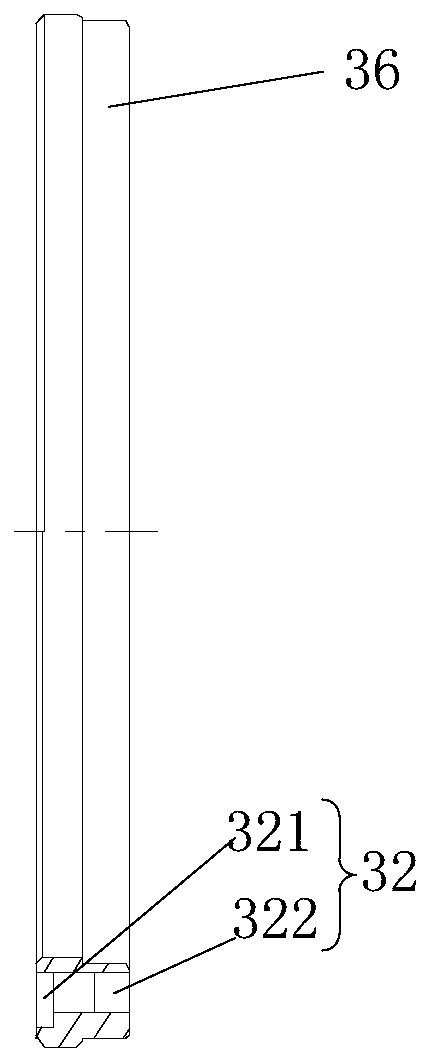

[0038] Such as Figure 1-Figure 5 As shown, Embodiment 1 of the present invention provides a tracer screen, which includes: an oil casing 1, a filter sleeve 2, and a tracer ring 3; the wall of the oil casing 1 is provided with a through hole 11; the The side wall of the filter sleeve 2 has a filter mesh hole 21, the filter sleeve 2 is set on the outer surface of the oil casing 1, and one end is connected to the outer wall of the oil casing 1, and the inner surface of the filter sleeve 2 is connected to the outer surface of the oil casing 1. There is a gap between the outer surfaces of the oil casing 1; the inside of the tracer ring 3 is provided with an accommodating space 31, and the accommodating space 31 is filled with a tracer 4, and the tracer ring 3 Both ends are in communication with the accommodating space 31, the tracer ring 3 is set on the oil casing 1, one end is connected with the other end of the filter sleeve 2, and communicates with the gap, and the other end is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com