Multifunctional foam fracturing fluid and preparation method thereof

A foam fracturing fluid and multi-functional technology, applied in the field of foam fracturing fluid, can solve the problems of unable to carry proppant, reduce hydraulic fracture conductivity, consume hydrogen ions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

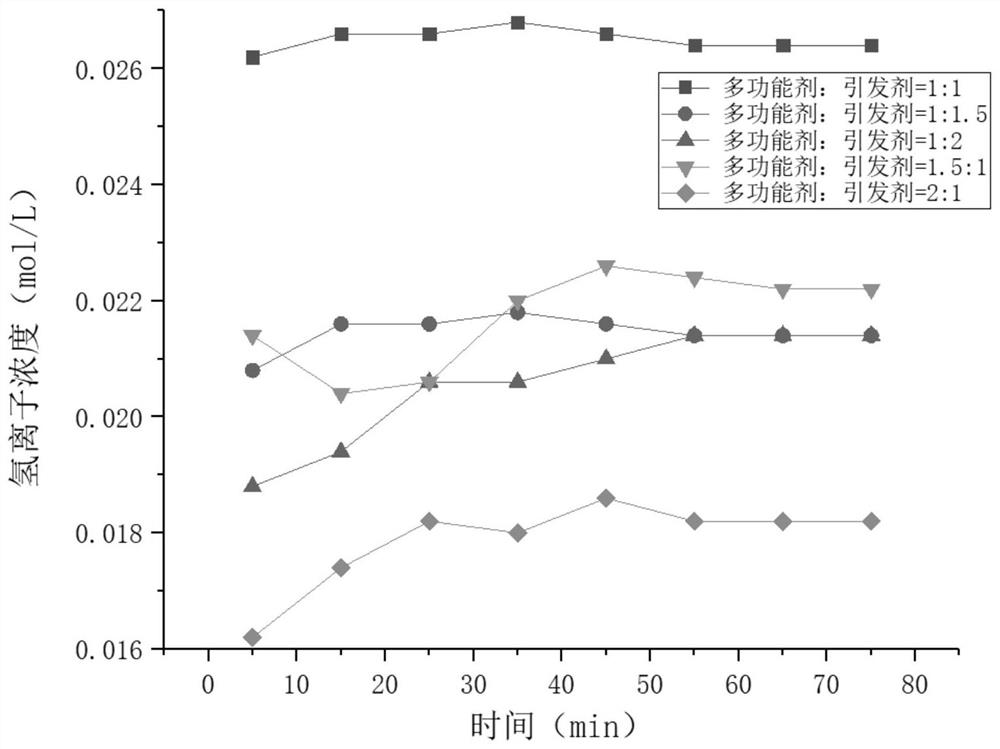

[0043] 0.3wt% multifunctional agent and 0.3wt% initiator are mixed with different volume ratios, and the acid concentration curve at normal temperature is obtained. It can be seen from the figure that at normal temperature, multifunctional agent and initiator can be mixed In the next five minutes, the acid will be generated quickly, and when the volume ratio is 1:1, the concentration of the obtained acid solution will be the highest, that is, this ratio can reduce the pH value of the system environment to the lowest level, which is beneficial to the subsequent multifunctional agent and self-gasification Agents get angry under strong acidic conditions.

Embodiment 2

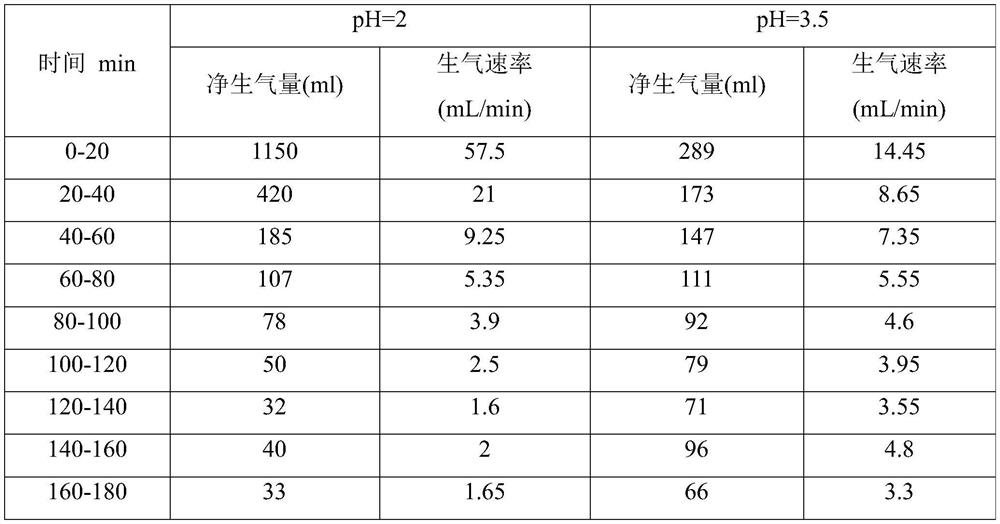

[0045] Mix 0.1 mol of multifunctional agent and 0.1 mol of self-generating agent at a volume ratio of 1:1 to form a 200ml solution, take half of the solution volume, adjust its pH value to 2, and adjust the pH value of the other half volume to 3.5. Put the two together in a water bath at 60°C, and measure the amount and speed of gas generation of the two in different time periods. See Table 1 below for specific data. It can be seen from the table that the stronger the acidity of the self-generating system, the greater the amount of gas generation and the higher the gas generation speed, which is more conducive to the subsequent generation of self-generating foam.

[0046] Table 1 At 60°C, the effect of pH value on the amount and speed of gas generation

[0047]

Embodiment 3

[0049] Mix 0.1 mol of multifunctional agent and 0.1 mol of self-generating agent at a volume ratio of 1:1 to form a 200ml solution, take half of the solution volume, adjust its pH value to 2, and adjust the pH value of the other half volume to 4.8. Put the two together in a water bath at 30°C, and measure the amount and speed of gas generation of the two in different time periods. See Table 2 below for specific data. It can be seen from the table that the stronger the acidity of the self-generating system, the greater the amount of gas generation and the higher the gas generation speed, which is more conducive to the subsequent generation of the self-generating foam system.

[0050]Table 2 The effect of pH value on the amount and speed of gas generation at 30°C

[0051]

[0052]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com